Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

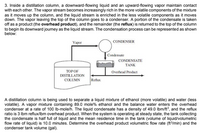

Transcribed Image Text:3. Inside a distillation column, a downward-flowing liquid and an upward-flowing vapor maintain contact

with each other. The vapor stream becomes increasingly rich in the more volatile components of the mixture

as it moves up the column, and the liquid stream is enriched in the less volatile components as it moves

down. The vapor leaving the top of the column goes to a condenser. A portion of the condensate is taken

off as a product (the overhead product), and the remainder (the reflux) is returned to the top of the column

to begin its downward joumey as the liquid stream. The condensation process can be represented as shown

below:

Vapor

CONDENSER

Condensate

CONDENSATE

TANK

Overhead Product

TOP OF

DISTILLATION

COLUMN

Reflux

A distillation column is being used to separate a liquid mixture of ethanol (more volatile) and water (less

volatile). A vapor mixture containing 89.0 mole% ethanol and the balance water enters the overhead

condenser at a rate of 100 Ib-mole/h. The liquid condensate has a density of 49.0 Ibm/ft°, and the reflux

ratio is 3 Ibm reflux/lbm overhead product. When the system is operating at steady state, the tank collecting

the condensate is half full of liquid and the mean residence time in the tank (volume of liquid/volumetric

flow rate of liquid) is 10.0 minutes. Determine the overhead product volumetric flow rate (ft/min) and the

condenser tank volume (gal).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 5 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Similar questions

- As a process engineer in the resin plant, you are dismayed to find in your morning round that the steam supply to your well stirred resin reactor was lost sometime between 6 and 8 AM. Luckily, the operator shut off the reactor feed and withdrawal streams, but the temperature of the resin in there is now falling as the log sheet shows. (Your capital request to improve reactor insulation got hung up in committee). If the resin in reactor gets down to 40 °C, it will begin to solidify and the cleanup will be a real mess. You decided to do a quick calculation to see how much time you have before this happens. Please present your analysis and calculations in the blank space below. Log Sheet Data Time Resin Temp. Ambient Temp. Notes °C °C 05:00 60 10 06:00 60 10 07:00 Lost steam, stop reactor flows 08:00 55 10 09:00 51 10arrow_forwardPlease include your diagram, mass balances, and full work. Thank you.arrow_forwardThe vapor leaving the top of a distillation column goes to a condenser in which either total or partial condensation takes place. If a total condenser is used, a portion of the condensate is returned to the top of the column as refcr and the remaining liquid is taken off as the overhead product (or distillate). If a partial condenser is used, the liquid condensate is returned as reflux and the uncondensed vapor is taken off as the overhead product. The overhead product from an n-butane-n-pentane distillation column is 93 mole% butane. The temperature of the cooling fluid limits the condenser temperature to 39 °C or higher. REFLUX DRUM a) Using Raoult's law, estimate the minimum pressure at which the condenser can operate as a partial condenser (i.e., at which it can produce liquid for reflux) b) The production rate of overhead product is 50 kmol/h, and the mole ratio of reflux to overhead product is 2:1. Calculate the molar flow rates and compositions of the reflux stream and the vapor…arrow_forward

- 05: Acetylene gas (C₂H₂) at 25 °C is burned during a steady-flow combustion process with 30 percent excess air at 27 °C. It is observed that 75x10³ kJ of heat is being lost from the combustion chamber to the surroundings per kmol of acetylene. Assuming combustion is complete, determine the exit temperature of the product gases.arrow_forwardLiquid gas undergoes combustion in air, releasing 100kf of heat and producing two gaseous products. Include energy in the reaction. When HCL reacts with NaOH to produce NaCl and H2O, 60kj of heat is released in the surroundings. a. State whether the surrounding gets warmer or colder. b. Sketch a PE graph for this reaction.arrow_forwardQ3(a) A stream of benzene vapor at 580 °C and 1 atm is cooled and converted to a liquid at 25 °C and latm in a continuous condenser. (i) (ii) Illustrate a completely process path for the above process. Calculate the total enthalpy change for this process.arrow_forward

- 8.29 Show complete solution and diagramarrow_forwardQ2: The feed to a distillation column is separated into net overhead product containing nothing with a boiling point higher than isobutane and bottoms containing nothing with a boiling point below that of propane. Hint: In the overhead there is no n-C5H12 or n-C4H10, and in the bottoms there in no C2H4, C2H6, or C3H6. The composition of the feed is mole % Ethylene 2.0 Ethane 3.0 Propylene Propane Isobutane 5.0 15.0 25.0 n-Butane 35.0 n-Pentane 15.0 Total 100.0 The concentration of isobutane in the overhead is 5.0 mole percent, and the concentration of propane in the bottoms is 0.8 mole percent. 1. Draw a completely labeled flowchart for the above process 2. Do the degree of freedom analysis for the overall processarrow_forwardThe fuel in the form of biogas (65%-mol CH4 and 35%-mol CO2) is burned in a furnace. In order for combustion to take place stoichiometrically, calculate the air to fuel ratio (vol/vol) from this problem!arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The