Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

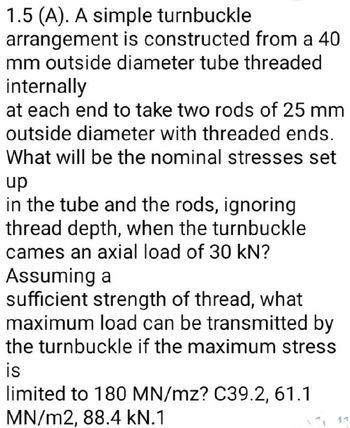

Transcribed Image Text:1.5 (A). A simple turnbuckle

arrangement is constructed from a 40

mm outside diameter tube threaded

internally

at each end to take two rods of 25 mm

outside diameter with threaded ends.

What will be the nominal stresses set

up

in the tube and the rods, ignoring

thread depth, when the turnbuckle

cames an axial load of 30 kN?

Assuming a

sufficient strength of thread, what

maximum load can be transmitted by

the turnbuckle if the maximum stress

is

limited to 180 MN/mz? C39.2, 61.1

MN/m2, 88.4 kN.1

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- Group5/Two fork end pieces are to be joined together by a single steel pin of 25mm diameter and they are required to transmit 50 kN. Determine the minimum cross-sectional area of material required in one branch of either fork if the stress in the fork material is not to exceed 180 MN/m². What will be the maximum shear stress in the pin?arrow_forwardProblem 1 only, solve carefully, include the units and dra the diagram. Thanks! . A taper pin is used to fix a lever to a shaft, if it is to transmit a maximum torque of 850 in-lb. The shaft diameter is 1.75inches and has an ultimate stress of 60,000 psi, if the factor of safety is 3, findA. Force that will shear the pin, kNB. Shear pin diameter, mmarrow_forward4: The boom AC is a 4-in. square steel tube with a wallthickness of 0.25 in. The boom is supported by the 0.5-in.-diameter pinat A, and the 0.375-in.-diameter cable BC. The working stresses are 25ksi for the cable, 18 ksi for the boom, and 13.6 ksi for shear in the pin.Neglect the weight of the boom.1. Calculate the maximum value of P (kips) based on boom compression and the maximum value of P (kips) based on tension in the cable.2. Calculate the maximum value of P (kips) based on shear in pin.arrow_forward

- The tensile load on the bar mentioned varies from 4,000 lb to a minimum of 1,200 lb. Rapid cycling for many million cycles is expected. As the tensile load fluctuates between 4,000 lb and 1,200 lb, it creates fluctuating normal stresses. Calculate the following stresses at the section through the hole. Note: SAE 1050 OQT 1300 steel, wrought steel (a) Maximum tensile stress (psi) (b) Minimum tensile stress (psi) (c) Median stress (psi)arrow_forwardSolveSample Problem 4.1.All remain as presented, except for the following changes.The factor ofsafety is now 2, and not 3.As Presented, the thickness of the tube is uniform. In the new one that you are solving,let the thicknessesof the top and bottom be the same,ttb, and the thicknesses of theleft and right be the same,tlr.Theheightand the width of the tube are still respectively 5 in and 3.25 in.As you make thesethickness changes,you are to keep thetotal mass of the tube unchanged. Answer the same questions (a) and (b).Explain your findingsarrow_forwardSolve the given problem. Show the FREE BODY DIAGRAM. Show the COMPLETE and CLEAR solution.arrow_forward

- A sleeve made of AISI 1040 CD steel has inner and outer diameters 40mm and 50mm, respectively. It is press fit on a solid shaft of same material with diameter 42mm such that the nominal diameter between sleeve and shaft became 41mm. a. Find the pressure developed between shaft and sleeve. b. Draw the tangential, radial, and total stress as a function of radius, for both sleeve and shaft. c. Find the maximum shaft diameter that can be used before failure.arrow_forward3.Shaft A, shown below, is made from AISI 1020 hot-rolled steel, welded to a fixed support, and is subjected to loading by equal and opposite forces F via shaft B. A theoretical stress-concentration factor Kts of 1.6 is induced by the 1/8" fillet. The length of shaft A from the fixed support to the connection at shaft B is 2 ft. The load F cycles from 150 to 500 lbf. (a) For shaft A, the factor of safety for infinite life using the Modified Goodman fatigue failure criterion is ( _) (b) For shaft A, the factor of safety for infinite life using the Gerber fatigue failure criterion is ( in fillet 2-in dia Shaft A 1 in 1 in Shaft Barrow_forwardA 1.25 in.-square steel punch is to push through an aluminum plate that is supported on a die, thus forming a square opening in the plate. a. If the allowable compressive stress in the plate is 24 ksi, what is the maximum punching force, in pounds, that this die can exert on the plate? b. If the aluminum has an ultimate shear strength of 6500 psi, find the maximum thickness t, in inches, through which a hole may be punched. Write to three decimal places. Punch force Steel punch Aluminum plate Die Punched piecearrow_forward

- i need the answer quicklyarrow_forwardPlease see attatchment and thank you.arrow_forwardProblem 2 only, solve carefully, include the units and dra the diagram. Thanks! A 3/4 inch diameter rivet is used to fastened two 25 mm thick plate. If the shearing stress of rivet is 80 Mpa, A. What tensile force applied each plate to shear the bolt, pounds?B. What bearing stress that the bolt can withstand, MPAarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY