Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

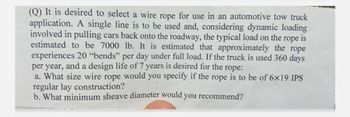

Transcribed Image Text:(Q) It is desired to select a wire rope for use in an automotive tow truck

application. A single line is to be used and, considering dynamic loading

involved in pulling cars back onto the roadway, the typical load on the rope is

estimated to be 7000 lb. It is estimated that approximately the rope

experiences 20 "bends" per day under full load. If the truck is used 360 days

per year, and a design life of 7 years is desired for the rope:

a. What size wire rope would you specify if the rope is to be of 6x19 IPS

regular lay construction?

b. What minimum sheave diameter would you recommend?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- Design a scissor jack for a typical vehicle.• Specify design considerations/requirements (weight to be lifted, initial position, final position, safety factor,etc.)• Specify dimensions and select material for all members. Use the same design channel (Ex. U-channel) forthe 4 major members. Consider buckling if the member is under compression. Specify thread dimension(including engagement length) for the center/horizontal memberarrow_forward3) A double screw (Acme thread angle o = 14.5) mechanism is designed to lift a load of 18,000 lb in such a way that screw is loaded in tension. Use of Safe Factor of safety of 3.2. Select a suitable screw from data table provided in class notes for tensile load and shear load. Limiting tensile and shear stresses are 10,000 psi and 5,500 psi, respectively. Required thickness of Yoke which functions as a nut. It is desired to raise the hatch a total of 30.0 inches in 15 seconds. Use coefficient of friction f= 0.15. List necessary assumptions. Sketch and Label a schematic diagram. Determine a. Nominal major diameter of screw (D) b. Threads per Inch of selected thread (n) c. Thickness of Yoke (h) d. Lead angle (2) e. Torque required to raise the load (Tup) f. Torque required to lower the load (Tdown) g. Efficiency of the screw h. RPM required to operate each screw i. Compute the Total Power required to operate the mechanism.arrow_forwardSubject is machine designarrow_forward

- Design a helical compression spring for a maximum load of 1000 N for a deflection of 25 mm using the value of spring index as 5. The operating load is considered as average load service. Choose a suitable material from table (23.1) for your design. If the same helical compression spring that was designed in Q1, is subjected to a load which vary from 200 N to 600 N. Based on the new condition, will the spring endure the new load? Consider that the allowable shear stress in table (23.1) is the yield stress and the endurance shear stress is 0.8 to 0.9 of the yield in shear. mechanical desgin pls solve fastarrow_forwardRope safety factor (Sf) in an elevator; It is a value that is directly dependent on the number of drive pulleys, deflector pulleys used, the shape of the rope bending, and the pulley channel angle. Determine the safety factor for the pulley-drum connection given below, using V-type pulleys with a channel angle of 35°. The rope diameter is 16 mm. (Include the selected table and the selection directions in the selected graphs).arrow_forwardA 3 x 8 member in a diaphragm resists a tension force caused by the lateral wind pressure. Lumber is Select Structural DF-L. A single line of 7/8 in. diameter bolts is used to make the connection of the member to the diaphragm. Cu = 1.0, C = 1.0, and C = 1.0. Find: a. The maximum axial tension load using ASD. b. The factored axial tension capacity using LRFD. Hint: This is a horizontal member with sheathing on top. Think carefully about orientation when computing the net area.arrow_forward

- (13%) Problem 5: A shop sign weighing m;g hangs from one end of a uniform beam weighing mpg. A hinge attaches the other end of the beam to a wall. The beam has a length of l1. A cable is attached to the beam a distance l2 from the hinge to help support the beam. The cable makes an angle 0 with the beam as shown. e 4 Paul's o o. Auto Repair E A 13% Part (a) On the following free body diagram, draw all of the forces acting on the beam, representing the forces as vectors. Use a coordinate systen with the x-axis on the horizontal (along the length of the beam) and the y-axis vertical (perpendicular to the beam). Use "wb" for the weight of the beam, "ws" for the weight of the sign, "FT" for the force of tension, and "H" for the force on the hinge. Finally, since we don't know the angle that the force on the hinge will act based on the diagram alone, let it be acting at an angle be denoted "o" from the positive y-axis. I A 13% Part (b) Using the free body diagram from part (a), write an…arrow_forward(2) A coil spring is to be used for the front suspension of a car. The spring is to have a rate of 400lb/in, an inside diameter of 4.0-in, & a free length of 14%-in, with squared & ground ends. The material is to be oil-tempered chrome-vanadium steel. Recommend the rod diameter & the number of coils for a design load of 1,500lb.arrow_forwardWrite legibly, provide step by step manual solution, and diagram for below given problem. An iron rod 6m long and 1.6mm2 in cross section stretches 1.2mm when a mass of 315kg is hang on it. Compute the modulus of elasticity of the iron. (Ans. E = 9656.72 Gpa)arrow_forward

- MACHINE DESIGN TOPIC A short compression member with Do = 2Di is tosupport a dead load of 25 tons. The material isto be 4130 steel, WQT 1100 F. Calculate theoutside and inside diameters in terms of incheson the basis of (a) yield strength, (b) ultimatestrength.*For 4130 steel, WQT 1100 FSu = 127 ksiSy = 114 ksi*Use the following Safety FactorsNu = 4Ny = 2arrow_forwardA uniform Steel strut (material Modulus of Elasticity 200 GN/m2, Poisson’s Ratio 0.3) oflength 0.5m and width 100 mm is restrained as appropriate at one end and under an axialtensile load of 25 KN applied to the other end face. It has been initially designed with a thickness of 5mm. This gives a hand calculated stressvalue of 50 MN/ m2, which is a quarter of the material’s Yield Stress, of 200 MN/m2, givinga factor of safety of four. Conduct computer FEA simulations applying element types(tetrahedral, hexahedral) and a range of element sizes (2mm, 5mm & 10mm), presenting findings in a tabulated format.arrow_forward1. Construct a critical end-load intensity against slenderness ratio graph for a range of pinned columns made from a material having a Young's Modulus of 200 GPa and a yield stress of Use slenderness ratios from 0 to 300. 30ОMPа.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY