Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

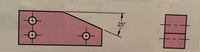

1. a. On the part shown, show a angularity specification to orient the angled surface in relation to the right surface in the side view and top surface in the front view within .005 total. Make sure to label the datum features.

b. Shoudl the 25 degree angle above have a plus/minus tolerance applied or should it be basic? Complete this requirement on the drawing.

c. What is the flatness tolerance on the angled surface above?

Transcribed Image Text:The image depicts a technical diagram of a mechanical part. The diagram consists of two main views:

1. **Top View**:

- This shows a rectangular part with a slanted top edge.

- There are three circular holes within the part, each marked with crosshairs indicating precise center points.

- The top right edge is cut at a 25-degree angle from the horizontal.

2. **Side View**:

- This view provides a vertical cross-section of the part.

- It shows the alignment of two of the circular holes visible from this perspective.

This diagram is useful for understanding both the shape of the part and the precise location of holes, which are critical for assembly or manufacturing processes.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Question 1 1. What is the philosophy of the Go and No-Go gauging? Explain in some details (need schematics) 2. Complete any missing information on part 1&2 and in feature control 1 &2 (assume any tolerance). Explain your analysis ..not just numbers. 3. Add all information needed for Gage 1 & 2 used to inspect Part 1&2 (show your calculations) Part 1 Part 2 Ø1.000+.000 -.005 Ø1.005+.005 -.000 Ø.500+.000 -.005 +.005 Ø.505000 OØ. Ø. Gage 1 Gage 2 7.arrow_forwardQuestion 3 The figures (1&2) shows a Hole-Pattern as drawn and as inspected. fill table 1 and calculate the true position tolerance. Show your calculations. Please note: Dimensions shown is relative to the actual size As drawn 4XØ0500 -0.312 Oe.005(M A BC C Pattern-4 holes # 2 1.000 # 3 +) 1.500 +)arrow_forwardI need help solving problem numbers 4--15.arrow_forward

- Please Fill In the blanks where I have marked red X's using the questions and Image below. 1. On the drawing above, before any geometric controls are applied, what is the coaxility tolerance is implied between the diameters? 2. On the part above, apply datum feature symbols to create a datum axis A-B by using the right and left diamters. 3. Apply a position coaxility between the right and left diamter of 0.1 at MMC. 4. Apply a position tolerance to the large center diameter within a diameter of 0.3 in relation to the single datum axis established by both datum features A and B.arrow_forwardHello Sir,Good Evening. I have a question in my homework realated geometry tolerance lesson. The following below is my question. Please advice thank you. "What is the difference between position tolerance and orientation tolerance?"arrow_forwardState any three rules of orthographic parallel projection.arrow_forward

- i need the answer quicklyarrow_forwardOn the part shown, specify a geometric control to make the left surface in the front view perpendicular to the bottom surface within .005 total, and what would the the flatness on the left surface of the part above be? Can a datum or feature modifier be applied to this feature control frame? why or why not?arrow_forwardApply geometric tolerancing to part according to the instructions below. This exercise will provide you with experience in correctly applying and interpreting geometric tolerancing symbology. If you have trouble applying the symbols, page through this unit looking for similar examples. The Hole Bar in this unit is a good reference. Draw symbols and feature control frames clearly and neatly. 1. Establish the right face in the side view as datum feature A. Qualify this feature with a flatness of .005. 2. Establish the top surface in the front view as datum feature B. Qualify this feature with a perpendicularity of .005 to datum feature A. 3. Establish the left surface in the front view as datum feature C. Qualify this feature with a perpendicularity of .005 to datum features A and B. 4. Establish all necessary dimensions as basic. 5. Position the .250 hole within a diameter of .005 RFS relative to datum features A,B,C. 6. Position the three holes within a diamter of .012 at MMC relative…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY