Interpretation:

The cold working process required to produce 0.2 in. diameter of copper wire from the original rod of 2 in. diameter needs to be explained. The process needs to be explained with the hot working.

Concept introduction:

Cold working is a metal forming process performed below recrystallization temperature and hot working is done above the recrystallization temperature.

Answer to Problem 8.82P

73.33 % cold working is required to reduce the diameter of the copper rod from 2 inches to 0.26 in. at

Explanation of Solution

Given Information:

Calculation:

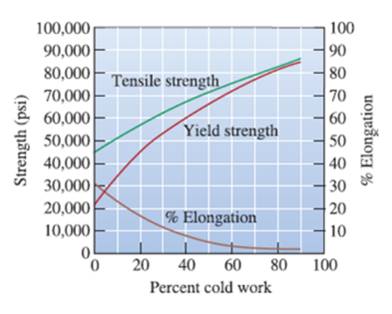

The figure shows the properties of copper versus the percentage of cold work.

From the figure, one can obtain the % of cold work for copper corresponding to 60000 psi yield strength and 5 % elongation as follows:

The % cold work is given to calculate the final diameter of the wire as follows:

Here,

To calculate the temperature,

Here,

Hence, annealing is done for 0.263 inches at

To calculate the percentage cold work for cold working to produce 1 in diameter wire from 2-inch diameter rod.

Hence, 75 % cold work is required to reduce from 2 into 1 in diameter at

Now, to calculate % of cold work to reduce diameter from 1 into 0.5 in.

Hence 75% cold work is needed toreduce diameter from 1 into 0.5 in at

To calculate % of the cold world to reduce diameter from 0.5 into 0.263 in.

Hence, 72.33 % cold work needed to reduce diameter from 0.5 into 0.263 in at

If cold working is replaced by hot working, then % hot work required to produces a diameter of 0.2 in from 2 in diameter rod is,

Thus, cold working and hot working formulas are same only hot working does not require, further annealing.

Want to see more full solutions like this?

Chapter 8 Solutions

Essentials Of Materials Science And Engineering

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY