Concept explainers

a)

To determine: The maximum number horse sculptures that can be made in an hour.

a)

Explanation of Solution

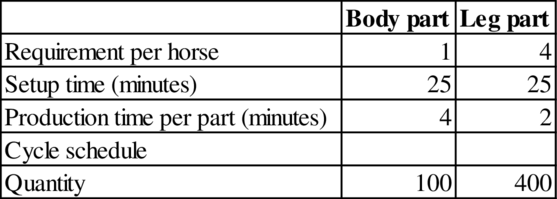

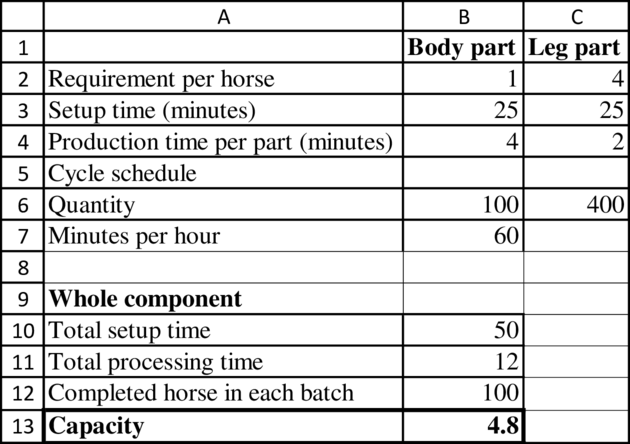

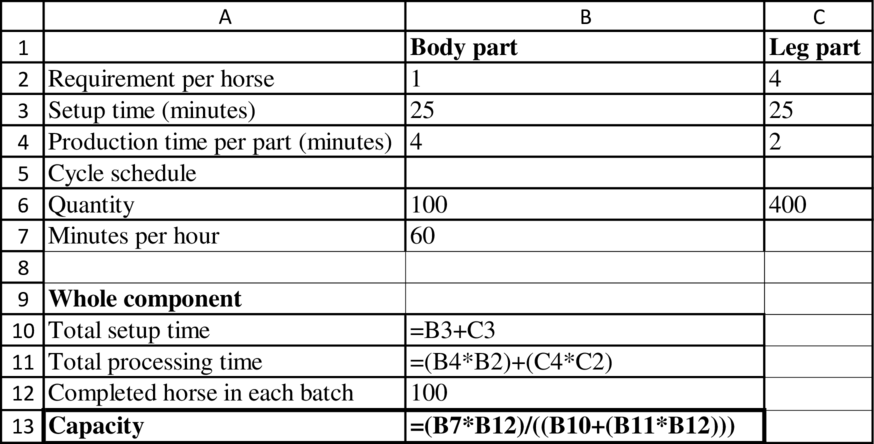

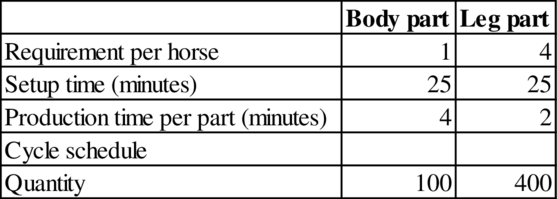

Given information:

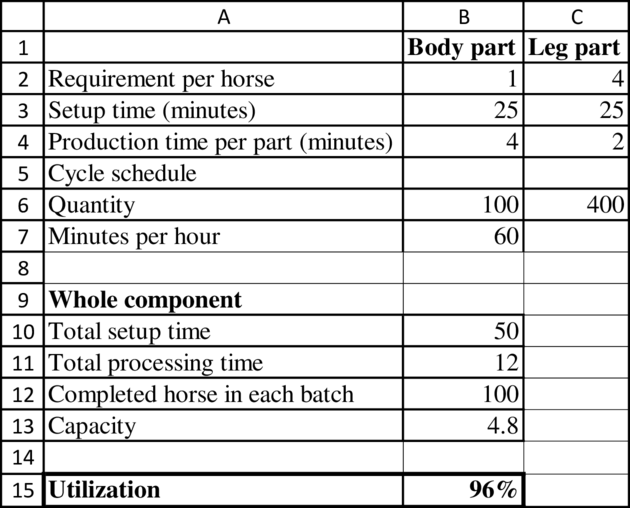

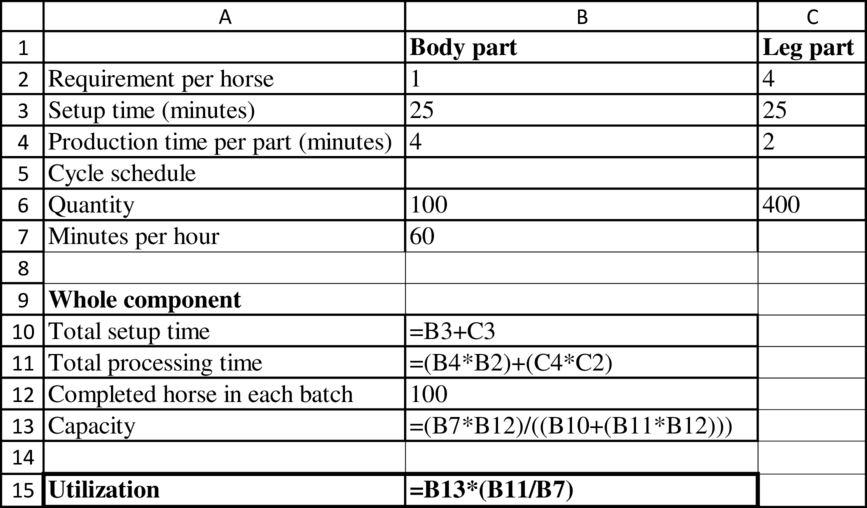

Calculation of maximum number of horses:

Formula:

The maximum number of horse sculptures made in an hour is 4.8.

b)

To determine: The utilization % of the lathe.

b)

Explanation of Solution

Given information:

Calculation of utilization of lathe:

Formula:

The utilization of lathe is 96%.

c)

To determine: The average inventory of body parts.

c)

Explanation of Solution

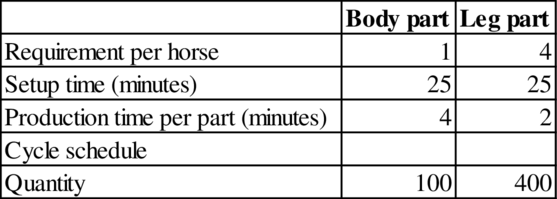

Given information:

1 worker can assemble the horse sculpture in 16 minutes.

Calculation of flow rate:

Calculation of average inventory:

The total batch size of legs is 100 and the processing time is 4 minutes.

The average inventory is 37.5 body.

d)

To determine: The average inventory of leg parts.

d)

Explanation of Solution

Given information:

1 worker can assemble the horse sculpture in 16 minutes.

Calculation of flow rate:

Calculation of average inventory:

The total batch size of legs is 400 and the processing time is 2 minutes.

The average inventory is 100 legs.

e)

To determine: The number of body parts that needs to be made to minimize the inventory while not constraining the flow through the assembly.

e)

Explanation of Solution

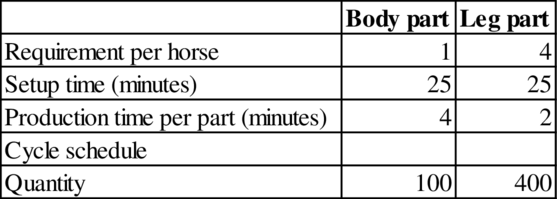

Given information:

1 worker can assemble the horse sculpture in 16 minutes.

Calculation of batch size:

The target capacity is the flow rate at 3.75 sculptures per hour. There is 1 body in each component set. Therefore, the batch size will be:

The body parts batch size is 12.5 body.

f)

To determine: The number of leg parts that needs to be made to minimize the inventory while not constraining the flow through the assembly.

f)

Explanation of Solution

Given information:

1 worker can assemble the horse sculpture in 16 minutes.

Calculation of batch size:

The target capacity is the flow rate at 3.75 sculptures per hour. There is 4 body in each component set. Therefore, the batch size will be:

The leg parts batch size is 50 leg.

Want to see more full solutions like this?

Chapter 7 Solutions

Operations Management

- Cablesplice, Inc.'s manufacturing process consists of five steps: making con- ductors, adding insulation, adding sheathing, irradiation, and printing and coil cuttingUnits are measured in meters. In 970,000 meters of cable, 700 defects were found in the conductors, and 75,000 defects were found in the insulation. In 440,000 meters of cable, 8,930 defects were found in the sheathing, and no defects were found in the remaining two steps. (a) Find DPU and the dpmo, and (b) the sigma level for each process step.arrow_forwardkareem is making a fruit salad made up of strawberries and bananas in a ratio of 5:3. how many cups of each are needed to make 160 cups of fruitarrow_forwardA production process at Kenneth Day Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). 7 units/hr 5 units/hr Assembly 0.8 units/hr Sawing Sanding Welding Assembly 2.1 units/hr 0.8 units/hr Drilling 2.5 units/hr Assembly 0.8 units/hr a) is the bottleneck. b) The bottleneck time is minutes per unit (round your response to two decimal places). c) The throughput time of the overall system is minutes (round your response to two decimal places).arrow_forward

- A machine makes two components; call them types A and B. It takes 630 seconds to switch production between the component types. During that time, no production occurs. When in production, each unit of A or B requires 0.5 second to be completed. The two components, A and B, are combined in an assembly process to make a final product; call it C. The assembly step can combine the two components into 1 unit every 4 seconds, or 15 units per minute. Suppose the machine rotates between one batch of 2,520 units of A and 2,520 units of B. In that case, what is the capacity of the machine in component pairs per minute, where a component pair is one unit of A and one unit of B?arrow_forwardA machine makes two components; call them types A and B. It takes 630 seconds to switch production between the component types. During that time, no production occurs. When in production, each unit of A or B requires 0.5 second to be completed. The two components, A and B, are combined in an assembly process to make a final product; call it C. The assembly step can combine the two components into 1 unit every 4 seconds, or 15 units per minute. Suppose the machine rotates between one batch of 2,520 units of A and 2,520 units of B. In that case, what is the capacity of the machine in component pairs per minute, where a component pair is one unit of A and one unit of B? Suppose the machine rotates between one batch of 2,520 units of A and 2,520 units of B. What is the utilization of the machine? Suppose the machine rotates between one batch of 2,520 units of A and 2,520 units of B. What is the average inventory of B components? If the production schedule could be adjusted with…arrow_forwardA machine makes two components; call them types A and B. It takes 250 seconds to switch production between the component types. During that time, no production occurs. When in production, each unit of A or B requires 0.5 second to be completed. The two components, A and B, are combined in an assembly process to make a final product; call it C. The assembly step can combine the two components into 1 unit every 2 seconds, or 30 units per minute. Assume there is ample demand. If the production schedule could be adjusted with the goal of minimizing inventory in the process, how many units of A should be produced before switching to component B? In other words, calculate the optimal batch size for component A. Assume the same number of units of B would be produced as well. answer:_______unitsarrow_forward

- The sales department clerk receives a customer orders from the customers and prepares a three-part sales order. The three copies are sent to the credit department for approval, where the clerk reviews the Customer Credit Records. After approval, the credit department clerk returns one copy of the sales order to the Sales Department, where it is reviewed and filed. The remaining two copies are sent to the warehouse. The Warehouse clerk picks the goods from the shelves and sends them along with one copy of the sales order to the shipping department. The third copy of the sales order is filed in the warehouse. Upon receipt if the goods, the shipping clerk prepares a shipping notice and sends the goods and one copy of the sales order to the customer. The clerk then sends the shipping notice to the Billing Department. Upon receipt of the shipping notice the billing clerk updates the customer’s account receivable and files the shipping notice in the department. Required Prepare a system…arrow_forwardA machine makes two components; call them types A and B. It takes 250 seconds to switch production between the component types. During that time, no production occurs. When in production, each unit of A or B requires 0.5 second to be completed. The two components, A and B, are combined in an assembly process to make a final product; call it C. The assembly step can combine the two components into 1 unit every 2 seconds, or 30 units per minute. Assume there is ample demand. Suppose the machine rotates between one batch of 1,000 untis of A and 1,000 units of B. In that case, what is the capacity of the machine in component pairs per minute, where a component pair is one unit of A and one unit of B? answer: __________ component pair per minutearrow_forwardA production process at Kenneth Day Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). 6 units/hr Sawing 2.5 units/hr Sanding Drilling 1.8 units/hr Welding 7 units/hr Assembly 0.7 units/hr Assembly 0.7 units/hr Assembly 0.7 units/hrarrow_forward

- The diagram below represents a process where two components are made at stations A1 and A2 (one component is made at A1 and the other at A2). These components are then assembled at station B and moved through the rest of the process, where some additional work is completed at stations C, D, and E. Assume that one and only one person is allowed at each station. Assume that the times given below for each station represent the amount of work that needs to be done at that station by that person, with no processing time variation. Assume that inventory is not allowed to build in the system. Al 0.3 min. A2 0.4 min. B 0.75 min. D 0.65 min. 0.60 min. E 0.55 min. What is the average hourly output of the process when it is in normal operation? Average hourly output unitsarrow_forwardThe diagram below represents a process where two components are made at stations A1 and A2 (one component is made at A1 and the other at A2). These components are then assembled at station B and moved through the rest of the process, where some additional work is completed at stations C, D, and E. Assume that one and only one person is allowed at each station. Assume that the times given below for each station represent the amount of work that needs to be done at that station by that person, with no processing time variation. Assume that inventory is not allowed to build in the system. A1 0.30 min. B 0.75 min. 0.65 min. 0.90 min. 0.55 min. A2 0.40 min. What is the average hourly output of the process when it is in normal operation? (Round your answer to the nearest whole number.) Average hourly output unitsarrow_forwardThe following diagram represents a process where two components are made at stations A1 and A2 (one component is made at A1 and the other at A2). These components are then assembled at station B and moved through the rest of the process, where some additional work is completed at stations C, D, and E. Assume that one and only one person is allowed at each station. Assume that the times given for each station represent the amount of work that needs to be done at that station by that person, with no processing time variation. Assume that inventory is not allowed to build in the system. What is the average hourly output of the process when it is in normal operation?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.