Concept explainers

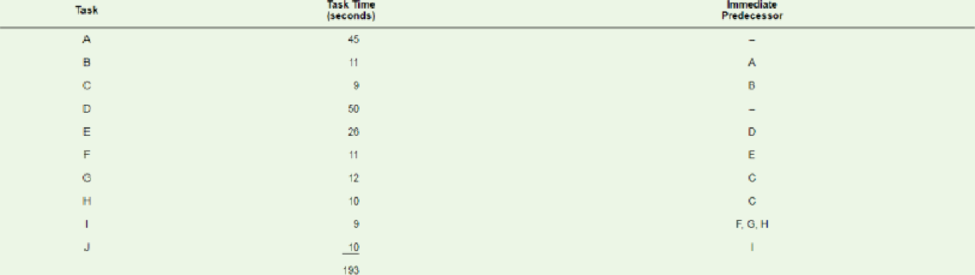

For the given set of tasks, do the following:

a. Develop the precedence diagram

b. Determine the minimum cycle time and then calculate the cycle time for a desired output of 500 units in a seven-hour day. Why might a manager use a cycle tune of 50 seconds?

c. Determine the minimum number of workstations for output of 500 units per day

d. Balance the line using the greatest positional weight heuristic. Break ties with the most following tasks heuristic. Use a cycle tune of 50 seconds.

e. Calculate the percentage idle time for the line.

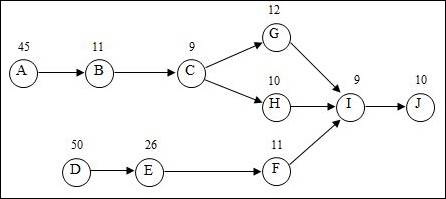

a)

To draw: The precedence diagram.

Introduction:

Process selection:

It is the tactical choices made by a firm in picking the kind of production procedure to be followed in the process of production. The process is selected after reviewing many numbers of criteria and constraints.

Answer to Problem 7P

Precedence diagram:

Explanation of Solution

Given information:

| Task | Task time (seconds) | Immediate predecessor |

| A | 45 | Nil |

| B | 11 | A |

| C | 9 | B |

| D | 50 | Nil |

| E | 26 | D |

| F | 11 | E |

| G | 12 | C |

| H | 10 | C |

| I | 9 | F, G , H |

| J | 10 | I |

| Total | 193 |

Precedence diagram:

The precedence diagram is drawn circles and arrows. The tasks are represented in circles and weights for each task are represented outside the circle. The arrows are represented to show which task is preceding the other task and so on.

b)

To determine: The minimum cycle time and the cycle time for the desired output.

Introduction:

Process selection:

It is the tactical choices made by a firm in picking the kind of production procedure to be followed in the process of production. The process is selected after reviewing many numbers of criteria and constraints.

Answer to Problem 7P

Explanation of Solution

Given information:

| Task | Task time (seconds) | Immediate predecessor |

| A | 45 | Nil |

| B | 11 | A |

| C | 9 | B |

| D | 50 | Nil |

| E | 26 | D |

| F | 11 | E |

| G | 12 | C |

| H | 10 | C |

| I | 9 | F, G , H |

| J | 10 | I |

| Total | 193 |

Operating hours per day = 7

Sum of all task times = 193 seconds

Desired output per day = 500

Calculation of minimum cycle time:

The minimum cycle time is equal to the time of the longest task.

The minimum cycle time is 50 seconds / unit.

Calculation of cycle time for the desired output:

The cycle time is calculated by dividing the operating time per day in seconds by the desired output per day.

The cycle time for the desired output is 50.4 seconds / unit.

The manager might use a cycle time of 50 seconds because it is closer to the calculated time. Also the task times are integers giving it a good chance to balance the line effectively.

c)

To determine: The minimum number of workstations for the desired output.

Introduction:

Process selection:

It is the tactical choices made by a firm in picking the kind of production procedure to be followed in the process of production. The process is selected after reviewing many numbers of criteria and constraints.

Answer to Problem 7P

Explanation of Solution

Given information:

| Task | Task time (seconds) | Immediate predecessor |

| A | 45 | Nil |

| B | 11 | A |

| C | 9 | B |

| D | 50 | Nil |

| E | 26 | D |

| F | 11 | E |

| G | 12 | C |

| H | 10 | C |

| I | 9 | F, G , H |

| J | 10 | I |

| Total | 193 |

Operating hours per day = 7

Sum of all task times = 193 seconds

Desired output per day = 500

Calculation of minimum number of workstations:

The minimum number of workstations is calculated by dividing the sum of all task times with the calculated cycle time.

The minimum number of workstations for the desired output is 4 workstations.

d)

To assign: Tasks on the basis of greatest positional weight.

Introduction:

Process selection:

It is the tactical choices made by a firm in picking the kind of production procedure to be followed in the process of production. The process is selected after reviewing many numbers of criteria and constraints.

Explanation of Solution

Given information:

| Task | Duration (minutes) | Immediate (Predecessor) |

| a | 0.1 | Nil |

| b | 0.2 | a |

| c | 0.9 | b |

| d | 0.6 | c |

| e | 0.1 | Nil |

| f | 0.2 | d, e |

| g | 0.4 | f |

| h | 0.1 | g |

| i | 0.2 | h |

| j | 0.7 | i |

| k | 0.3 | j |

| l | 0.2 | k |

Cycle time = 50 seconds

The number of following tasks, calculation of positional weight for each task is shown below.

| Task | Following tasks | Number of following tasks | Calculation of positional weight | Positional weight |

| A | B, C, G, H, I, J | 6 | 45 + 11 + 9 + 12 + 10 + 9 + 10 | 106 |

| B | C, G, H, I, J | 5 | 11 + 9 + 12 + 10 + 9 + 10 | 61 |

| C | G, H, I, J | 4 | 9 + 12 + 10 + 9 + 10 | 50 |

| D | E, F, I, J | 4 | 50 + 26 + 11 + 9 + 10 | 106 |

| E | F, I, J | 3 | 26 + 11 + 9 + 10 | 56 |

| F | I, J | 2 | 11 + 9 + 10 | 30 |

| G | I, J | 2 | 12 + 9 + 10 | 31 |

| H | I, J | 2 | 10 + 9 + 10 | 29 |

| I | J | 1 | 9 + 10 | 19 |

| J | Nil | 0 | 10 | 10 |

Assigning tasks to workstations:

| Workstation number | Eligible task | Assigned task | Task time | Unassigned cycle time | Reason |

| 50 | |||||

| 1 | A, D | A | 45 | 5 | Task 'A' has more following tasks |

| B, D | None | 5 (Idle time) | The task time is greater than the unassigned cycle time. | ||

| 50 | |||||

| 2 | B, D | D | 50 | 0 | Task 'D' has the highest positional weight |

| 50 | |||||

| 3 | B, E | B | 11 | 39 | Task 'B' has the highest positional weight |

| C, E | E | 26 | 13 | Task 'E' has the highest positional weight | |

| C, F | C | 9 | 4 | Task 'C' has the highest positional weight | |

| F, G, H | None | 4 (Idle time) | The task time is greater than the unassigned cycle time. | ||

| 50 | |||||

| 4 | F, G, H | G | 12 | 38 | Task 'G' has the highest positional weight |

| F, H | F | 11 | 27 | Task 'F' has the highest positional weight | |

| H | H | 10 | 17 | Task 'H' is the only eligible task available | |

| I | I | 9 | 8 | Task 'I' is the only eligible task available | |

| J | None | 8 (Idle time) | The task time is greater than the unassigned cycle time. | ||

| 50 | |||||

| 5 | J | J | 10 | 40 | Task 'J' is the only task remaining |

| 40 (Idle time) | All tasks completed |

Overview of tasks assignment:

| Workstation | Assigned tasks | Total cycle time used | Idle time |

| 1 | A | 45 | 5 |

| 2 | D | 50 | 0 |

| 3 | B, E, C | 46 | 4 |

| 4 | G, F, H, I | 42 | 8 |

| 5 | J | 10 | 40 |

e)

To determine: The percentage of idle time.

Introduction:

Process selection:

It is the tactical choices made by a firm in picking the kind of production procedure to be followed in the process of production. The process is selected after reviewing many numbers of criteria and constraints.

Answer to Problem 7P

Explanation of Solution

Formula to calculate percentage of idle time:

Calculation of percentage of idle time:

The percentage of idle time is 22.80%.

Want to see more full solutions like this?

Chapter 6 Solutions

Operations Management

- As part of a major plant renovation project, the industrial engineering department has been askedto balance a revised assembly operation to achieve an output of 240 units per eight-hour day. Tasktimes and precedence relationships are as follows: [ please refer the attachment for addl details ] Do each of the following:a. Draw the precedence diagram.b. Determine the minimum cycle time, the maximum cycle time, and the calculated cycle time.c. Determine the minimum number of stations needed.d. Assign tasks to workstations on the basis of most following tasks. Use shortest processing timeas a tiebreaker. If ties still exist, assume indifference in choice.e. Compute the percentage of idle time for the assignment in part d.arrow_forwardThe City Commission of Nashville has decided to build a botanical garden and picnic area in the heart of the city for the recreation of its citizens. The precedence table for all the activities required to construct this area successfully is as follows: Code Description A BCDEFGH G I Find location; determine resource requirements Requisition of lumber and sand Dig and grade Saw lumber into appropriate sizes Position lumber in correct locations Nail lumber together Put sand in and under the equipment Put dirt around the equipment Put grass all over the garden, landscape, paint Time (hrs) 20 60 100 35 20 10 20 30 Immediate Predecessor(s) None A A B D, C E F F- G, H Refer to the legend for the activity that corresponds to each code. Using the line drawing tool, draw a Gantt chart for activities E through I of the project.arrow_forwardA company needs to rebalance a product layout for producing new plastic license plates. They plan to use the assembly line six hours in order to meet projected demand of 2,160 license plates each day. The following table describes the tasks involved in the production of this product: Without regard to projected demand, what is the maximum possible cycle time for this assembly line? Task Time (secs) Immediate Predecessor a 3 none b 4 none c 5 a,b d 7 none e 9 c,darrow_forward

- Use excel to show formulas 1. A company is designing a product layout for a new product. They plan to use this production line 16 hours a day in order to meet forecasted demand of 1200 units per day. For output to equal forecasted demand, what should be the actual cycle time for this production?arrow_forwardThe City Commission of Nashville has decided to build a botanical garden and picnic area in the heart of the city for the recreation of its citizens. The precedence table for all the activities required to construct this area successfully is as follows: A- Time B- Code Description (hrs) Immediate Predecessor(s) C- A Find location; determine resource requirements 25 None Requisition of lumber and sand Dig and grade Saw lumber into appropriate sizes 55 A D- C 100 A E- 30 В E Position lumber in correct locations 20 D, C F- F Nail lumber together 10 E G- Put sand in and under the equipment Put dirt around the equipment G 25 F H F H- Put grass all over the garden, landscape, paint 35 G, H Refer to the legend for the activity that corresponds to each code. Using the line drawing tool, draw a Gantt chart for activities E through I of the project. 20 40 60 80 100 120 140 160 180 200 220arrow_forwardDraw a preceding diagram and assign task to stations in order of most following tasks firstarrow_forward

- Use the longest work element rule to balance the assembly line described in the following table and Figure so that it will produce 40 units per hour.a. What is the cycle time?b. What is the theoretical minimum number of workstations?c. Which work elements are assigned to each workstation?d. What are the resulting efficiency and balance delay percentages?e. Use the shortest work element rule to balance the assembly line. Do you note any changes in solution? Work Element Time (Sec) Immediate Predecessor(s) A B C D E F G H I J K 40 80 30 25 20 15 60 45 10 75 15 None A A B C B B D E,G F H,I,Jarrow_forwardThe City Commission of Nashville has decided to build a botanical garden and picnic area in the heart of the city for the recreation of its citizens. The precedence table for all the activities required to construct this area successfully is as follows: Code A B с D E F G H I Description Find location; determine resource requirements Requisition of lumber and sand Dig and grade Saw lumber into appropriate sizes Position lumber in correct locations Time (hrs) 20 60 100 30 20 10 20 10 30 Nail lumber together Put sand in and under the equipment Put dirt around the equipment Put grass all over the garden, landscape, paint Refer to the legend for the activity that corresponds to each code. Using the line drawing tool, draw a Gantt chart for activites E through I of the project. Immediate Predecessor(s) None A A B D, C E F F G, H A B C- D- E F G H- H 0 20 40 60 80 100 120 140 160 180 200 Q ✔arrow_forwardKarina Nieto works for New Products Inc., and one of hermany tasks is assigning new workers to departments. Thecompany recently hired six new employees and would likeeach one to be assigned to a different department. The em-ployees have completed a two-month training session ineach of the six departments from which they received theevaluations shown below (higher numbers are better).Determine how the new employees should be assigned todepartments so that overall performance is maximized.arrow_forward

- Amelio Rodriguez Computing wants to establish an assembly line for producing a new product, the Personal Digital Assistant (PDA). The tasks, task times, and immediate predecessors for the tasks are as follows: Task A B с D E Amelio's goal is to produce 175 PDAs per hour. a) The cycle time for the production of a PDA = Time (sec) 12 14 8 4 20 Immediate Predecessor A A B, C D seconds (round your response to two decimal places). b) The theoretical minimum number of workstations that Amelo can achieve in this assembly line fround your response up to the next whole number). = Were you able to assign all the tasks to the theoretical minimum number of workstations? c) For one to assign the tasks to the actual workstations and be able to use the theoretical minimum number, the activity assignment should be Workstation Tasks Assigned to Workstationarrow_forwardA manager wants to assign tasks to workstations as efficiently as possible and achieve an hourlyoutput of four units. The department uses a working time of 56 minutes per hour. Assign the tasksshown in the accompanying precedence diagram (times are in minutes) to workstations using thefollowing rules:a. In order of most following tasks. Tiebreaker: greatest positional weight.b. In order of greatest positional weight. Tiebreaker: most following tasks.c. What is the efficiency?arrow_forwardA manager wants to assign tasks to workstations as efficiently as possible and achieve an hourly output of 331/3 units. Assume the shop works a 60-minute hour. Assign the tasks shown in the accompanying precedence diagram (times are in minutes) to workstations using the following rules: A. In order of most following tasks. Tiebreaker: greatest positional weight. Work Station Task I II III IV b. In order of greatest positional weight. Tiebreaker: most following tasks. Work Station Tasks I II III IV c. What is the efficiency? (Round your answer to 2 decimal places.) Efficiency _________%arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.