Concept explainers

Twelve tasks, with times and precedence requirements as shown in the following table, are 10 be assigned to workstations using a cycle time of 1.5 minutes. Two heuristic rules will be tried: (1) greatest positional weight, and (2) most following tasks. In each case, the tiebreaker will be shortest processing time.

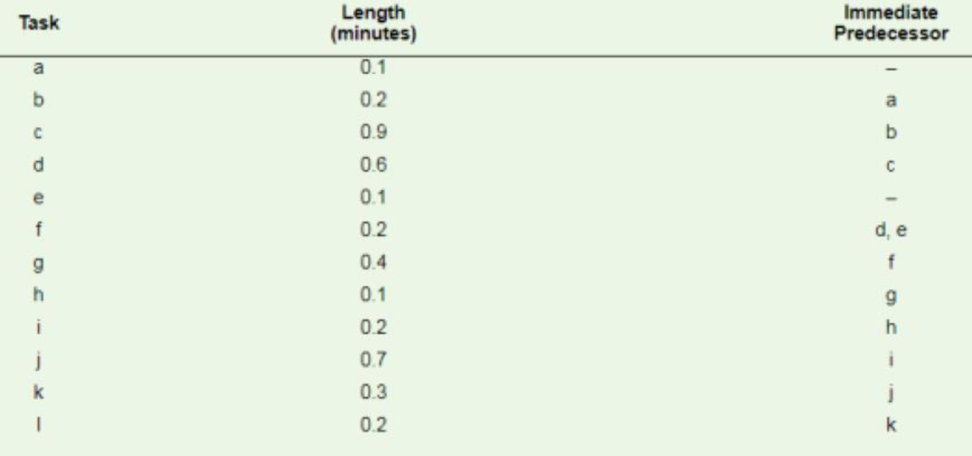

a. Draw the precedence diagram for this line.

b. Assign tasks to stations under each of the two rules.

c. Compute the percentage of idle tune fox each rule.

a)

To draw: The precedence diagram.

Answer to Problem 6P

Precedence diagram:

Explanation of Solution

Given information:

| Task | Duration (minutes) | Immediate (Predecessor) |

| a | 0.1 | Nil |

| b | 0.2 | a |

| c | 0.9 | b |

| d | 0.6 | c |

| e | 0.1 | Nil |

| f | 0.2 | d, e |

| g | 0.4 | f |

| h | 0.1 | g |

| i | 0.2 | h |

| j | 0.7 | i |

| k | 0.3 | j |

| l | 0.2 | k |

Cycle time = 1.5 minutes

Precedence diagram:

The precedence diagram is drawn circles and arrows. The tasks are represented in circles and weights for each task are represented outside the circle. The arrows are represented to show which task is preceding the other task and so on.

b)

1)

To assign: Tasks on the basis of greatest positional weight.

Explanation of Solution

Given information:

| Task | Duration (minutes) | Immediate (Predecessor) |

| a | 0.1 | Nil |

| b | 0.2 | a |

| c | 0.9 | b |

| d | 0.6 | c |

| e | 0.1 | Nil |

| f | 0.2 | d, e |

| g | 0.4 | f |

| h | 0.1 | g |

| i | 0.2 | h |

| j | 0.7 | i |

| k | 0.3 | j |

| l | 0.2 | k |

Cycle time = 1.5 minutes

The number of following tasks, calculation of positional weight, processing time for each task is shown below.

| Task | Following tasks | Number of following tasks | Calculation of positional weight | Positional weight | Processing time |

| a | b, c, d, f, g, h, i, j, k, l | 10 | 0.1 + 0.2 + 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.9 | 0.1 |

| b | c, d, f, g, h, i, j, k, l | 9 | 0.2 + 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.8 | 0.2 |

| c | d, f, g, h, i, j, k, l | 8 | 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.6 | 0.9 |

| d | f, g, h, i, j, k, l | 7 | 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.7 | 0.6 |

| e | f, g, h, i, j, k, l | 7 | 0.1 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.2 | 0.1 |

| f | g, h, i, j, k, l | 6 | 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.1 | 0.2 |

| g | h, i, j, k, l | 5 | 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 1.9 | 0.4 |

| h | i, j, k, l | 4 | 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 1.5 | 0.1 |

| i | j, k, l | 3 | 0.2 + 0.7+ 0.3 + 0.2 | 1.4 | 0.2 |

| j | k, l | 2 | 0.7+ 0.3 + 0.2 | 1.2 | 0.7 |

| k | l | 1 | 0.3 + 0.2 | 0.5 | 0.3 |

| l | Nil | 0 | 0.2 | 0.2 | 0.2 |

Assigning tasks to workstations:

| Workstation number | Eligible task | Assigned task | Task time | Unassigned cycle time | Reason |

| 1.5 | |||||

| 1 | a, e | a | 0.1 | 1.4 | Task 'a' has highest positional weight |

| b, e | b | 0.2 | 1.2 | Task 'b' has highest positional weight | |

| c, e | c | 0.9 | 0.3 | Task 'c' has highest positional weight | |

| d, e | e | 0.1 | 0.2 | Task 'e' is the only eligible task available | |

| d | None | 0.2 (Idle time) | The task time is greater than the unassigned cycle time. | ||

| 1.5 | |||||

| 2 | d | d | 0.6 | 0.9 | Task 'd' is the only eligible task available |

| f | f | 0.2 | 0.7 | Task 'f' is the only eligible task available | |

| g | g | 0.4 | 0.3 | Task 'g' is the only eligible task available | |

| h | h | 0.1 | 0.2 | Task 'h' is the only eligible task available | |

| i | i | 0.2 | 0 | Task 'i' is the only eligible task available | |

| 1.5 | |||||

| 3 | j | j | 0.7 | 0.8 | Task 'j' is the only eligible task available |

| k | k | 0.3 | 0.5 | Task 'k' is the only eligible task available | |

| l | l | 0.2 | 0.3 | Task 'l' is the only eligible task available | |

| 0.3 (Idle time) | All tasks completed |

Overview of tasks assignment:

| Workstation | Assigned tasks | Total cycle time used | Idle time |

| 1 | a, b, c, e | 1.3 | 0.2 |

| 2 | d, f, g, h, i | 1.5 | 0 |

| 3 | j, k, l | 1.2 | 0.3 |

2)

To assign: Tasks on the basis of most following tasks.

Explanation of Solution

Given information:

| Task | Duration (minutes) | Immediate (Predecessor) |

| a | 0.1 | Nil |

| b | 0.2 | a |

| c | 0.9 | b |

| d | 0.6 | c |

| e | 0.1 | Nil |

| f | 0.2 | d, e |

| g | 0.4 | f |

| h | 0.1 | g |

| i | 0.2 | h |

| j | 0.7 | i |

| k | 0.3 | j |

| l | 0.2 | k |

Cycle time = 1.5 minutes

The number of following tasks, calculation of positional weight, processing time for each task is shown below.

| Task | Following tasks | Number of following tasks | Calculation of positional weight | Positional weight | Processing time |

| a | b, c, d, f, g, h, i, j, k, l | 10 | 0.1 + 0.2 + 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.9 | 0.1 |

| b | c, d, f, g, h, i, j, k, l | 9 | 0.2 + 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.8 | 0.2 |

| c | d, f, g, h, i, j, k, l | 8 | 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.6 | 0.9 |

| d | f, g, h, i, j, k, l | 7 | 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.7 | 0.6 |

| e | f, g, h, i, j, k, l | 7 | 0.1 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.2 | 0.1 |

| f | g, h, i, j, k, l | 6 | 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.1 | 0.2 |

| g | h, i, j, k, l | 5 | 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 1.9 | 0.4 |

| h | i, j, k, l | 4 | 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 1.5 | 0.1 |

| i | j, k, l | 3 | 0.2 + 0.7+ 0.3 + 0.2 | 1.4 | 0.2 |

| j | k, l | 2 | 0.7+ 0.3 + 0.2 | 1.2 | 0.7 |

| k | l | 1 | 0.3 + 0.2 | 0.5 | 0.3 |

| l | Nil | 0 | 0.2 | 0.2 | 0.2 |

Assigning tasks to workstations:

| Workstation number | Eligible task | Assigned task | Task time | Unassigned cycle time | Reason |

| 1.5 | |||||

| 1 | a, e | a | 0.1 | 1.4 | Task 'a' has the most following tasks |

| b, e | b | 0.2 | 1.2 | Task 'b' has the most following tasks | |

| c, e | c | 0.9 | 0.3 | Task 'c' has the most following tasks | |

| d, e | e | 0.1 | 0.2 | Task 'e' is the only eligible task available | |

| d | None | 0.2 (Idle time) | The task time is greater than the unassigned cycle time. | ||

| 1.5 | |||||

| 2 | d | d | 0.6 | 0.9 | Task 'd' is the only eligible task available |

| f | f | 0.2 | 0.7 | Task 'f' is the only eligible task available | |

| g | g | 0.4 | 0.3 | Task 'g' is the only eligible task available | |

| h | h | 0.1 | 0.2 | Task 'h' is the only eligible task available | |

| i | i | 0.2 | 0 | Task 'i' is the only eligible task available | |

| 1.5 | |||||

| 3 | j | j | 0.7 | 0.8 | Task 'j' is the only eligible task available |

| k | k | 0.3 | 0.5 | Task 'k' is the only eligible task available | |

| l | l | 0.2 | 0.3 | Task 'l' is the only eligible task available | |

| 0.3 (Idle time) | All tasks completed |

Overview of tasks assignment:

| Workstation | Assigned tasks | Total cycle time used | Idle time |

| 1 | a, b, c, e | 1.3 | 0.2 |

| 2 | d, f, g, h, i | 1.5 | 0 |

| 3 | j, k, l | 1.2 | 0.3 |

c)

To determine: The percentage of idle time.

Answer to Problem 6P

Explanation of Solution

Formula to calculate percentage of idle time:

Calculation of percentage of idle time:

The solutions for most following tasks rule and highest positional weight is same. Hence, the percentage of idle time will also be the same.

The percentage of idle time is 11.11%.

Want to see more full solutions like this?

Chapter 6 Solutions

Loose-leaf for Operations Management (The Mcgraw-hill Series in Operations and Decision Sciences)

- Given the following information, assign tasks to work stations using the most followers rule. Assume the cycle time is 60 seconds and the minimum number of workstations is 3. Submit for each workstation (1,2,3,4 etc.), the tasks assigned in order of assignment, the idle time for each work station and the total idle time. (It will help for you to make the diagram but you are not required to submit the diagram) Task A D w Immediate Predecessor D CE Task Time (seconds) 35 50 20 10 25 40arrow_forwardGlaudious is 45 years old university internship coordinator. He is handling 80 interns and he would like to perform the following tasks in an easy and fast way. He also encountered an accident a year ago which caused his right leg to have a bone minor fracture which caused him to limit the place he can go. He would like that he can perform the tasks anytime and anywhere. Below are the tasks of Prof Glaudios. 1) He registers the students undergoing internship, this includes the term in a schoolyear, the company name where the student is undergoing internship, directsupervisor of the intern, start of duty, Number of Hours of duty per day, andthe Job of the student-intern in the company. 2) He will also view the following: a) Individual internship record in a term-sem-school year b) Interns details in a company Based on the scenario above, model the tasks of Prof Glaudious by creating a Task Analysis.arrow_forwardGlaudious is 45 years old university internship coordinator. He is handling 80 interns and he would like to perform the following tasks in an easy and fast way. He also encountered an accident a year ago which caused his right leg to have a bone minor fracture which caused him to limit the place he can go. He would like that he can perform the tasks anytime and anywhere. Below are the tasks of Prof Glaudios. 1) He registers the students undergoing internship, this includes the term in a schoolyear, the company name where the student is undergoing internship, directsupervisor of the intern, start of duty, Number of Hours of duty per day, andthe Job of the student-intern in the company. 2) He will also view the following: a) Individual internship record in a term-sem-school year b) Interns details in a company using the Professor Glaudious Scenario, provide the requirements specification: a. Functional b. Data c. Environmental d. User e. Usabilityarrow_forward

- 1.Explain the concepts of scheduling and sequencing 2.Describe staff scheduling and appointment system decisions 3.Describe how to solve two-resource sequencing problems.arrow_forwardThere are six jobs as below. The processing time (in days) and due date for each job are below. Job |arrow_forwardThere are six jobs as below. The processing time (in days) and due date for each job are below. Job lamolam A B C D E F (a) the average flow time Processing Time (days) (b) average tardiness 1 16 4 10 5 8 Due Date (days from present time) Please use SPT (shortest processing time) priority rule to calculate: 7 16 4 15 10 18 (c) average number of jobs at the work center, for each of these rules:arrow_forwardFour automobiles have entered Bubba’s Repair Shop for various types of work, ranging from a transmis-sion overhaul to a brake job. The experience level of the mechanics is quite varied, and Bubba would liketo minimize the time required to complete all of thejobs. He has estimated the time in minutes for eachmechanic to complete each job. Billy can completejob 1 in 400 minutes, job 2 in 90 minutes, job 3 in60 minutes, and job 4 in 120 minutes. Taylor willfinish job 1 in 650 minutes, job 2 in 120 minutes, job3 in 90 minutes, and job 4 in 180 minutes. Mark willfinish job 1 in 480 minutes, job 2 in 120 minutes, job3 in 80 minutes, and job 4 in 180 minutes. John willcomplete job 1 in 500 minutes, job 2 in 110 minutes,job 3 in 90 minutes, and job 4 in 150 minutes. Eachmechanic should be assigned to just one of these jobs.What is the minimum total time required to finish thefour jobs? Who should be assigned to each job?arrow_forwardGiven the following information, assign tasks to work stations using the most followers rule. Assume the cycle time is 60 seconds. Submit for each workstation (1,2,3 etc.), the tasks assigned in order of assignment, the idle time for each work station and the total idle time. (It will help for you to make the diagram but you are not required to submit the diagram) Immediate Task Task Time (seconds) Predecessor 35 50 A. 20 10 25 F\ C.E 40 Edit Format Table Paragraph V BIUA 12pt v Immediate Predecessor Task Time (seconds) Taskarrow_forwardI only need help with question 4, but question 3 explains how to do 4 but I'm lost. I already have question 3 done. 3. Sequence the jobs shown below by using a Gantt chart. Assume that the move time between machines is one hour. Sequence the jobs in priority order 1, 2, 3, 4. Job Work Center/Machine Hours Due Date (days) Job 1 A/3, B/2, C/2 Job 2 C/2, A/4 Job 3 B/6, A/1, C/3 Job 4 C/4, A/1, B/2 a. What is the makespan? b. How much machine idle time is there? c. When is each job delivered compared with its due date? d. How much idle time (waiting time) is there for each job? e. Devise a better job sequence for processing. 4. In problem 3, assume there are two machines of type A, two of type B, and two of type C. a. Prepare a finite capacity schedule. b. Compare the FCS to the Gantt chart in problem 3.arrow_forwardThe times required to complete each of eight jobs in a two-machine flow shop are shown in the table that follows. Each job must follow the same sequence, beginning with machine A and moving to machine B. TIME (hours) Job Machine A Machine B a 16 5 b 3 13 c 8 7 d 9 6 e 2 14 f 14 4 g 18 14 h 20 11 Find machine B’s idle time For the sequence determined in part a, how much would machine B's idle time be reduced by splitting the last two jobs in half?arrow_forwardThe three-station work cell at Pullman Mfg., Inc. is illustrated in the figure below. It has two machines at station 1 in parallel (i.e., the product needs to go through only one of the two machines before proceeding to station 2). 20 min/unit Station 1 Machine A Station 1 Machine B 20 min/unit Station 2 12 min/unit b) The bottleneck time of this work cell is number). Station 3 6 min/unit a) The throughput time is minutes (enter your response as a whole number). minutes per unit (enter your response as a whole c) is the bottleneck station. d) If the firm operates 8 hours per day, 6 days per week, the weekly capacity of this work cell is units (enter your response as a whole number).arrow_forwardA B1 B2 B3 C1 C2 C3 D1 D2 D3 E A service process is described by the above flowchart. After going through workstation A, an order needs to be processed by one of the three lines, B1-C1-D1, B2-C2-D2, or B3-C3-D3 (in other words, they are substitutable). Finally, all orders need to go through workstation E. The capacities of the individual workstations are given as follows: Workstation A has a capacity of 3 orders/hour • Workstation B1, B2, and B3 have the same capacity of 4 orders/hour • Workstation C1, C2, and C3 have the same capacity of 3 orders/hour • Workstation D1, D2, and D3 have the same capacity of 4 orders/hour • Workstation E has a capacity of 6 orders/hour What is process time of this service process in minutes?arrow_forwardarrow_back_iosSEE MORE QUESTIONSarrow_forward_ios

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.