Concept explainers

(a)

The amount of alpha and gamma phases at temperature

(a)

Answer to Problem 5.62P

The amount of alpha and gamma phases at temperature

Explanation of Solution

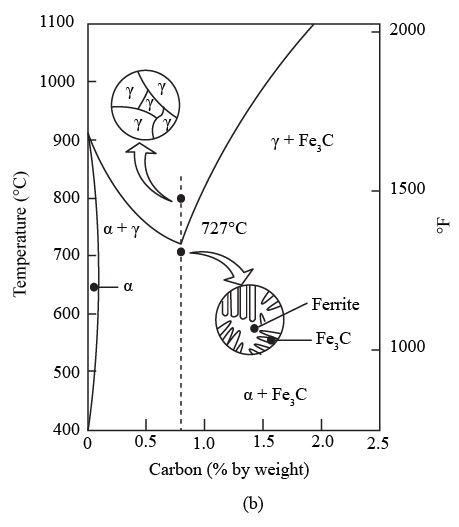

Figure 5.4b

Figure drawn below shows the detailed view of microstructure above and below the eutectoid temperature of

Figure 2

At

Conclusion:

Therefore, the amount of alpha and gamma phases at temperature

(b)

The amount of alpha and gamma phases at temperature

(b)

Answer to Problem 5.62P

The amount of alpha and gamma phases at temperature

Explanation of Solution

Formula used:

The expression for the alpha percentage is given as,

Here,

The expression for the gamma percentage is given as,

Calculation:

The alpha percentage can be calculated as,

The gamma percentage can be calculated as,

Conclusion:

Therefore, the amount of alpha and gamma phases at temperature

(c)

The amount of alpha and gamma phases at temperature

(c)

Answer to Problem 5.62P

The amount of alpha and gamma phases at temperature

Explanation of Solution

At

Formula used:

The expression for the alpha percentage is given as,

Calculation:

The alpha percentage can be calculated as,

Conclusion:

Therefore, the amount of alpha and gamma phases at temperature

Want to see more full solutions like this?

Chapter 5 Solutions

Manufacturing Processes for Engineering Materials (6th Edition)

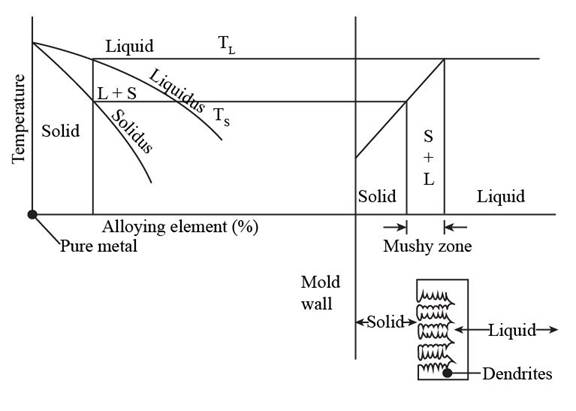

- (9,00 Puanlar) 36 - A riser in the shape of a sphere is to be designed for a sand casting mold. The casting is a rectangular plate, with length = 25 cm, width = 15 cm, and thickness = 2,5 cm. If the total solidification time of the casting itself is known to be 4,5 min, determine the diameter of the riser so that it will take 2596 longer for the riser to solidify. Riser volume: V-(nD³/6 (D=diameter) Riser area: A-TD2 Casting volume: V-L-W-t (L-Length, W=width, t=thickness)arrow_forward(9,00 Puanlar) A riser in the shape of a sphere is to be designed for a sand casting mold. The casting is a rectangular plate, with 8- length 50 cm, width = 35 cm, and thickness = 4 cm. If the total solidification time of the casting itself is known to be 7,5 min, determine the diameter of the riser so that it will take 30% longer for the riser to solidify. %3D Riser volume: V3(TD3)/6(D%3Ddiameter) Riser area: A=TD2 Casting volume: V-L-Wt (L-Length, W=width, t-thickness) a) 8,41 cm b) O 7,34 cm c) 6.62 cm 11,46 cm Boş bırak KÖnceki 8/43 Sonraki> Каpatarrow_forwardWhen casting a 4x10x20 in. Part, which has a top overflow with a H / D = 1.5 ratio, you want to determine the height and diameter of the overflow to prevent shrinkage in the part to be cast. Note: Remember that to achieve this, the overflow has to solidify some time after the piece has solidified, since in this case the overflow acts as a riser.arrow_forward

- Volume of a cube of side / and volume of a sphere of radius rare equal. Both the cube and the sphere are solid and of same material. They are being cast. The ratio of the solidification time of the cube to the same of sphere is 3. 6. 4T (a) 6. 4T (b) 6. 3. 4 4T (c) 6. (d) 6.arrow_forward2b) Figure 3 shows a cooling curve of Cadmium (Cd). Determine (i) the solidification temperature;(ii) the superheat;(iii) the cooling rate, just before solidification begins; (iv) the total solidification time; (v) the local solidification time; and(vi) If the cooling curve was obtained at the center of the casting sketched in the figure, determine the mold constant, assuming that n = 2.arrow_forward2. In the casting of steel under certain mould conditions, the mould constant in Chvorinov's rule is known to be 4.0 min/cm?, based on previous experience. The casting is a flat plate whose length is 25 cm, width is 8 cm, and thickness is 2.5 cm. Exponent n is taken to have a value of 2. Determine how long it will take for the casting to solidify.arrow_forward

- (b) Describe the following process in metal casting: (i) Melting process (ii) Pouring process (iii) Solidifying processarrow_forwardIn sand casting of hollow part of lead, a cylindrical core of diameter 120 mm and height 180 mm is placed inside the mould cavity. The densities of core material and lead are 1600 kg/m3 and 11300 kg/m³ respectively. The net force (in N) that tends to lift he core during pouring of molten metal will bearrow_forwardQ4(a). Sand casting is one of the basic process in metal casting. Illustrate a schematic diagram of a sand-casting mould and explain the function of it features.arrow_forward

- Q3. a) What the structural changes occurring during the annealing of steel casting? (Explain and draw)arrow_forwardA flat plate is to be cast in an open mold whose bottom has a square shape that is 200 mm by 200 mm. The mold is 40 mm deep. A total of 106 mm3 of molten aluminum is poured into the mold. Solidification shrinkage is known to be 6.0%. The linear shrinkage due to thermal contraction after solidification is 1.3%. If the availability of molten metal in the mold allows the square shape of the cast plate to maintain its 200 mm by 200 mm dimensions until solidification is completed, determine the final dimensions of the plate.arrow_forwardQ6 Use the Iron carbon diagram to find 4 of the following. ( 1- The range of solidification temp. (start to end of solidification) for cast iron with 3% C. 2- The solid and liquid percent for Cast Iron with 2.7%C at 1320 °C. 3- Draw the expected microstructure at room temp. for hypo-eutectoid steel with 0.7%C. 4- Draw the expected cooling curve from the melting point to room temp. for cast iron with 4.3%C. 5- The steps and the allotropy change for steel with 0.01%C.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY