Concept explainers

a)

To determine: The labor content.

a)

Explanation of Solution

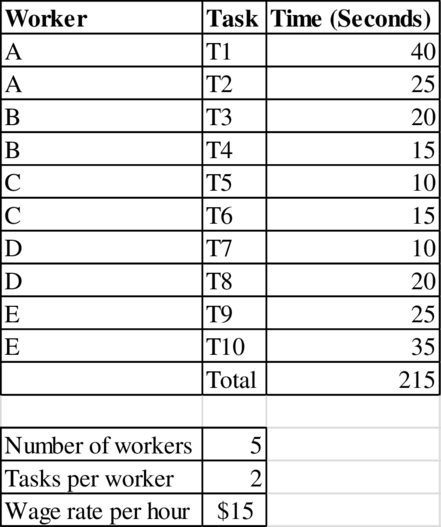

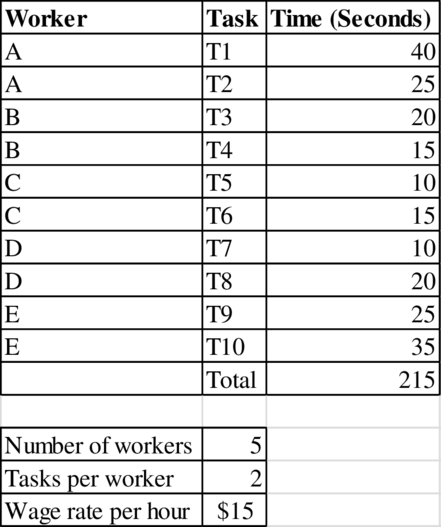

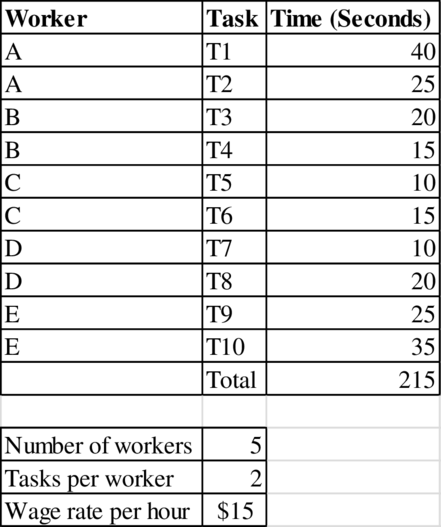

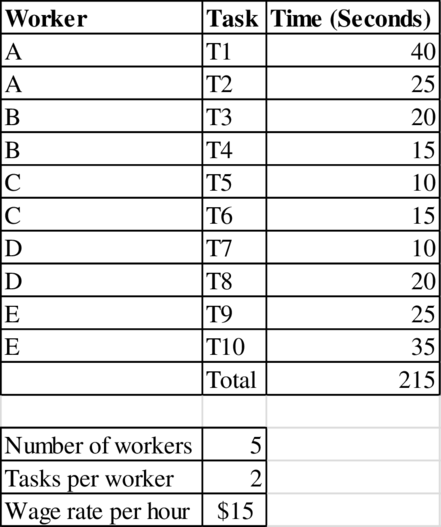

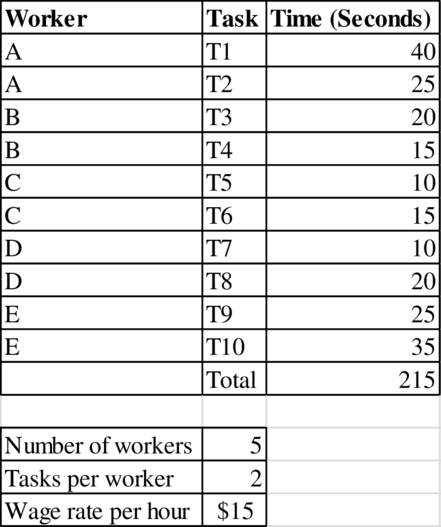

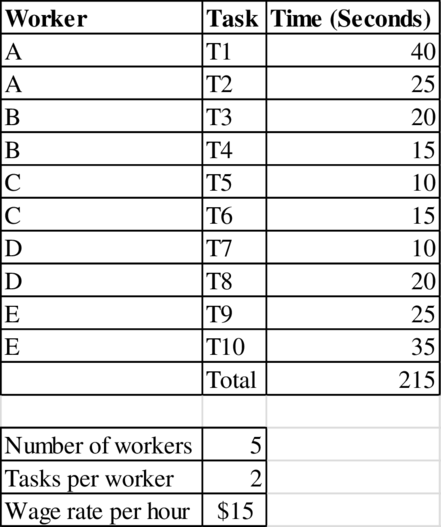

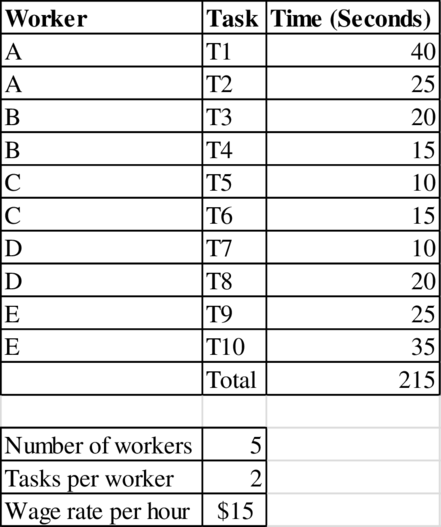

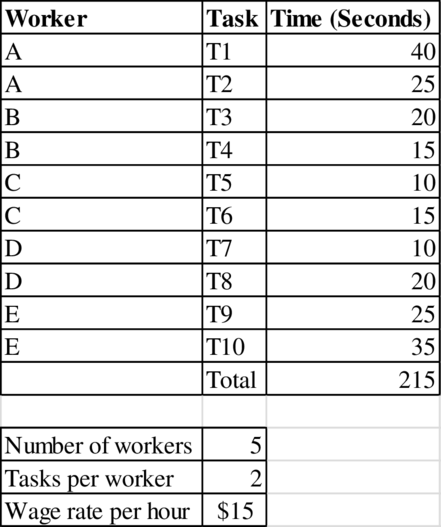

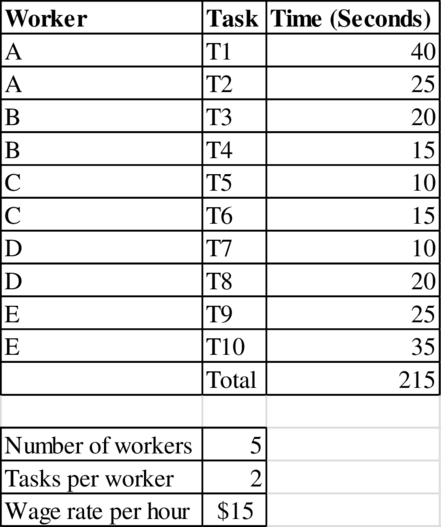

Given information:

Labor content:

The labor content is total time required to perform all the tasks of by the workers. It is 215 seconds.

The labor content is 215 seconds.

b)

To determine: The cost of direct labor for a toothbrush.

b)

Explanation of Solution

Given information:

Calculation of time per worker:

The time for Worker A is 65 seconds.

The time for Worker B is 35 seconds.

The time for Worker C is 25 seconds.

The time for Worker D is 30 seconds.

The time for Worker E is 60 seconds.

The bottleneck is Worker A with 65 seconds. Therefore, the flow rate will be:

Cost of direct labor:

The cost of direct labor per toothbrush is $1.35.

c)

To determine: The utilization of worker A.

c)

Explanation of Solution

Given information:

Utilization of Worker A:

The time for Worker A is 65 seconds. It is the bottleneck time of the entire process. Therefore, the utilization is 100%.

The utilization of 100%.

d)

To determine: The average labor utilization of the process.

d)

Explanation of Solution

Given information:

Average labor utilization of the process:

The cycle time will be equal to the bottleneck time which is 65 seconds. The average labor utilization will be:

The average labor utilization of 66.15%.

e)

To determine: The Takt time.

e)

Explanation of Solution

Given information:

Demand rate = 40 toothbrushes per hour

Takt time:

The Takt time is 90 second per toothbrush.

f)

To determine: The target manpower.

f)

Explanation of Solution

Given information:

Takt time = 50 seconds

Target manpower

The target manpower is 4.3 workers.

g)

To determine: The capacity of the process after hiring the new worker.

g)

Explanation of Solution

Given information:

New capacity of the process:

The new worker is added to Task 1 and Task 2 as it is the bottleneck of the process. After the addition of the new worker, the bottleneck is Worker E with a total time of 60 seconds. Therefore, the new capacity will be:

The capacity of process is 60 toothbrushes per hour.

h)

To determine: The capacity of the process.

h)

Explanation of Solution

Given information:

New capacity of the process:

The tasks are assigned to minimize the maximum work across the various workers. Task 1 is assigned to Worker A. Tasks 2, 3 is assigned to Worker B. Tasks 4, 5, 6, and 7 is assigned to Worker C. Tasks 8, 9 is assigned to Worker D. Task 10 is assigned to Worker E. The bottleneck time now is Worker 3 with 50 seconds. Therefore, the capacity is:

The capacity of process is 60 toothbrushes per hour.

i)

To determine: The capacity of the process with the new method

i)

Explanation of Solution

Given information:

New capacity of the process:

The capacity of process is 83.7 toothbrushes per hour.

Want to see more full solutions like this?

Chapter 4 Solutions

Operations Management

- A process has seven elements composed of combination of worker and machine. Elements A, B, D, and F are worker-controlled while elements C and E are machine controlled. Element G is a worker-controlled irregular element performed every five cycles Machines are idle during elements A, D, and G. Two units are produced every cycle. Below are the observed time (in minutes) and performance rating of each element. Work Element Observed Time (in minutes) Performance Rating A 0.75 115% B 1.20 120% C 1.40 N.A. D 1.05 90% E 1.25 N.A. F 1.20 105% G 1.60 85% Worker's allowance is 20% a) Determine Normal Time . Answer in 4 decimal placesb) What is the standard time? Round up answer in 2 decimal places.c) If the worker's performance during actual production is 125% on all manual elements for seven hours worked on an eight-hour shift, how many units will be produced? Round up answer in integer value.d) Determine the worker's efficiency (in percentage). Answer in 2 decimal placesarrow_forwardThree employees at a fast-food restaurant each perform one of the three activities in serving a customer: take the order, process the order, and deliver the order. The processing time for each activity is given as follows: Activity Processing Time Take the order 30 seconds Process the order 2 minutes Deliver the order 1 minute Assume that the demand is 20 customers/hour. What is the average labor utilization? a 38.9% b 85.7% c 66.7% d 100%arrow_forwardcompany that processes fruits and vegetables is able to produce 500 cases of canned peaches in 1.5 hours with four workers. Each worker is paid 2 Rials per hour. What is labor productivity in terms of cases/labor hour, cases rial?arrow_forward

- Four employees at a fast-food restaurant each perform one of the four activities in serving a customer: greet customer, take order, process order, and deliver order. The processing time for each activity is given as follows: Greet customer Take order Process order Deliver order A) 50% Assume demand is unlimited. What is the average labor utilization? B) 68% C) 40% Activity D) 162% Processing time per customer 2 seconds 30 seconds 60 seconds 5 secondsarrow_forwardIf the overhead rate is $10 per machine hour and there are 20 labor hours, 16 machine hours, and twopersonnel on the job, how much overhead should be applied to the job?arrow_forwardThree professors are grading a combined final exam. Each is grading different questions on the test. One professor requires three minutes to finish her portion, a second takes six minutes, and the third takes two minutes. Assume that there is no learning curve effect. a) What will be their hourly output? b) If there are 45 tests to grade, how long will the grading take? c) If each professor were to grade the exams separately in 18 minutes, how long would it take to grade the 45 tests? How long if another professor (who also required 18 minutes) joined them? d) If another professor pitches in just to help the second professor in the original arrangement, how long will it take the four of them to grade the tests? e) If a fifth professor offers to help, what might happen? *Need answers for parts d and e only*arrow_forward

- Smartphones are made on a 40-step assembly process. All 40 steps are connectedthrough a conveyor belt and all of the 40 steps must work at the same rate even if someof them have more capacity than others. Is this process a machine-paced process or aworker-paced process?a. Machine-pacedb. Worker-pacedarrow_forwardene is working with the operations manager to determine what the standard labor cost is for a spice chest. He has watched the process from start to finish and taken detailed notes on what each employee does. The first employee selects and mills the wood, so it is smooth on all four sides. This takes the employee 1 hour(s) for each chest. The next employee takes the wood and cuts it to the proper size. This takes 43 minutes. The next employee assembles and sands the chest. Assembly takes 3 hour(s). The chest then goes to the finishing department. It takes 3 hour(s) to finish the chest. All employees are cross-trained so they are all paid the same amount per hour, $17.62. What is the standard cost per chest for labor? Round to the nearest penny, two decimal places.arrow_forwardWith respect to products, we might say that an item is worth what a customer will pay for it. Can we say, with respect to wages, that a job is worth what a qualified person will take to do it? Why or why not?arrow_forward

- Consider the example of the three-step process. The first step takes 20 minutes/unit, the second step takes 10 minutes/unit, and the third step takes 15 minutes/unit. Eachstep is staffed by one worker. What is the labor content of the process?arrow_forwardEsplanade Marine Parts Inc. wants to produce parts in batches of 60 parts. Each part must be processed sequentially from workstation A to B. Processing Workstation Batch Size (Q) Time per Part 40 seconds A B 60 60 15 seconds a. How many seconds are required to produce the batch under the assumptions of batch processing? Round your answer to the nearest whole number. seconds b. How many seconds are required to produce the batch under the assumptions of single-piece flow processing? Round your answer to the nearest whole number. seconds C. Compare the two solutions in terms of time saved. Round your answer to the nearest whole number. Using the assumptions of -Select- processing saves seconds.arrow_forwardThe concept that relates to gaining efficiency through the full utilization of dedicated resources, such as people and equipment.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.