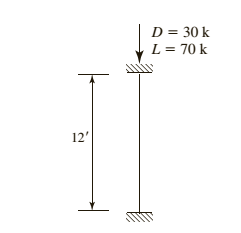

(a)

To select:

American standard channel for the given compression member using LRFD.

Answer to Problem 4.8.4P

Explanation of Solution

Given information:

Given compression member is :

Calculation:

Calculate the factored load by LRFD by using the equation.

Here

Substitute

Try a C section

AISC must be used, as this shape is non slender and is neither a double angle nor a tee shape

Check the effective slenderness ratio about y-axis using the formula.

Here K is the effective length factor

L is the length of the member between the supports.

r is the radius of gyration

Take the properties steel from the AISC steel table. K value depends on the end conditions

Calculate the elastic buckling stress using the formula.

Check for slenderness ratio by using the formula.

Here

Substitute

Since

Calculate the nominal compressive strength of column using the formula.

Substitute,

=

=

Calculate design strength of the column using by LRFD method

Here we have

Check the effective slenderness ratio about x-axis using the formula.

Substitute

From the manual companion CD:

Calculate the elastic buckling stress using the formula.

Calculate the value of

Calculate the total stress by equation

Calculate the value of

In order to determine which compressive strength equation to be use, compare the value of

Since

Calculate the maximum strength by using the formula.

.

Conclusion:

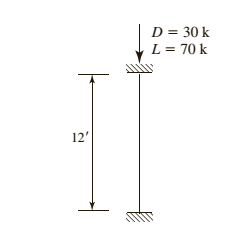

(b)

To select:

American standard channel for the given compression member using ASD.

Answer to Problem 4.8.4P

Explanation of Solution

Given information:

Given compression member is

Calculation:

Calculate the factored load by LRFD by using the equation.

He re

Substitute

Try a C section

AISC must be used, as this shape is non slender and is neither a double angle nor a tee shape

Check the effective slenderness ratio about y-axis using the formula

Here K is the effective length factor

L is the length of the member between the supports

r is the radius of gyration

Take the properties steel from the AISC steel table. K value depends on the end conditions

Calculate the elastic buckling stress using the formula.

Check for slenderness ratio by using the formula.

Here

Substitute

Since

Calculate the nominal compressive strength of column using the formula.

Substitute,

=

=

Calculate design strength of the column using by ASD method.

Here we have

Check the effective slenderness ratio about x-axis using the formula.

Substitute

From the manual companion CD:

Calculate the elastic buckling stress using the formula.

Calculate the value of

Calculate the total stress by equation

Calculate the value of

In order to determine which compressive strength equation to be use, compare the value of

Since

Calculate the maximum strength by using the formula.

Conclusion:

Want to see more full solutions like this?

Chapter 4 Solutions

STEEL DESIGN (LOOSELEAF)

- 7 7a 7b 7c Alaterally supported beam was designed for flexure. The beam is safe for shear & deflection. The most economical section is structural tubing however the said section is not readily available at the time of the construction. If you are the engineer in charge of the construction what alternative section will be the best replacement? Why? The section is 8" x 8" x 7.94 mm thick: Use Fy=248 MPa: E=200,000 MPa AISC wall thickness Ix 106 S x 103 Jx 103 mm4 mm3 mm4 rx =ry Area Ag (mm2) mm Designation Weight/m 8x8 7.94 47.36 6,039 79.25 37.84 371.99 60.35 expla'n briefly your cho'ce. (transform your comparative analys's 'nto a narative form to support your cho'ce) 8x8 14.29 80.61 10,258 76.2 59.52 585.02 99.06 8x8 72.7 9,290 76.96 54.53 539.13 90.32 8x8 9.53 56.09 7,161 78.48 44.12 432.62 70.76 mm 12.7 Zx 103 mm3 437.53 714.48 650.57 512.92arrow_forwardQ1:A: The Ix6 in. plate shown in Figure below is connected to a lx10 in. plate with longitudinal fillet welds to transfer a tensile load. Determine the LRFD design tensile strength of the member if F, = 50 ksi and Fu = 65 ksi. PLI X 10 in PL1 x 6 in P P w= 6 in Longitudinal fillet welds L=8 inarrow_forwardA PL 38 X 6 tension member is welded to a gusset plate as shown. The steel is A36 (Fy = 36ksi, Fu = 58ksi). a. The design strength, Pu based on gross area b. The design strength, Pu based on effective area PL % x6 3/8" 6" Cross Sectional area of PL3/8x6 a) Blank 1 b) Blank 2arrow_forward

- The lap joint in the figure is fastened by four 20 mm Ø A325X bolts. Calculate the maximum safe load P that can be applied if the plates are 25 mm thick A-36 steel Use ASD. 4 @ 40 mm P 2 @ 60 mm Parrow_forwardA structural tee bracket is attached to a column flange with six bolts as shown in Figure . All structural steel is A992. Check this connection for compliance with the AISC Specification. Assume that the bearing strength is controlled by the bearing deformation strength of 2.4dtFu. a. Use LRFD. b. Use ASD.arrow_forward4.3-4 Determine the available strength of the compression member shown in Figure P4.3-4. in each of the following ways: a. Use AISC Equation E3-2 or E3-3. Compute both the design strength for LRFD and the allowable strength for ASD. 15 HSS 10x6x ASTM A500, Grade B steel (Fy=46 ksi) 2/3arrow_forward

- 2) Find the axial stresses of menbers FD, GD, GE State if it is tensile or Compressive. 4M 3M A LE 3m G 20 RN Go KNarrow_forwardThe given beam is laterally supported at the ends and at the 1 3 points (points 1, 2, 3, and 4). The concentrated load is a service live load. Use Fy=50 ksi and select a W-shape. Do not check deflections. a. Use LRFD. b. Use ASD.arrow_forward

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning