Certain solid substances, known as hydrated compounds, have well-defined molecular ratios of water to some other species. For example, calcium sulfate dihydrate (commonly known as gypsum, CaSO42H2O), has 2 moles of water per mole of calcium sulfate; alternatively, it may be said that 1 mole of gypsum consists of 1 mole of calcium sulfate and 2 moles of water. The water in such substances is called water of hydration. (More information about hydrated salts is given in Chapter 6.)

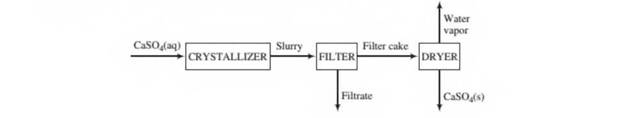

In order to eliminate the discharge of sulfuric acid into the environment, a process has been developed in which the acid is reacted with aragonite (CaCO3) to produce calcium sulfate. The calcium sulfate then comes out of solution in a crystallizer to form a slurry (a suspension of solid particles in a liquid) of solid gypsum particles suspended in an aqueous CaSO4 solution. The slurry flows front tlte crystallizer to a filter in which the particles arc collected as a filter cake. The filter cake, which is 95.0 wt% solid gypsum and the remainder CaSO4 solution, is fed to a dryer in which all water (including the water of hydration in the crystals) is driven off to yield anhydrous (water-free) CaSO4 as product A flowchart and relevant process data arc given below.

Solids content of slurry leaving crystallizer 0.35 kg CaSO4-2H2O/L slurry CaSO4 content of slurry liquid: 0.209g CaSO4/100g H2O Specific gravities: CaSO4-2H2O(s), 2.32; liquid solutions, 1.05

- Briefly explain in your own words the functions of the three units (crystallizer, filter, and dryer).

- Take a basis of one liter of solution leaving the crystallizer and calculate tlte mass (kg) and volume (L) of solid gypsum, the mass of CaSO4 in the gypsum, and the mass of CaSO4 in the liquid solution.

- Calculate the percentage recovery of CaSO4—that is, the percentage of the total CaSO4(precipitated plus dissolved) leaving the crystallizer recovered as solid anhydrous CaSO4.

- List five potential negative consequences of discharging H2SO4 into the river passing the plant.

Want to see the full answer?

Check out a sample textbook solution

Chapter 3 Solutions

ELEM.PRIN.OF CHEM.PROCESS-ACCESS

Additional Engineering Textbook Solutions

Process Dynamics and Control, 4e

Elements of Chemical Reaction Engineering (5th Edition) (Prentice Hall International Series in the Physical and Chemical Engineering Sciences)

Starting Out with C++ from Control Structures to Objects (8th Edition)

Structural Analysis (10th Edition)

Experiencing MIS

C How to Program (8th Edition)

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The