Concept explainers

Case summary:

Person PH, the

To develop: A better schedule by reducing the number of orders and carrying some amount of inventory and identify the cost savings with the new schedule.

Explanation of Solution

Given information:

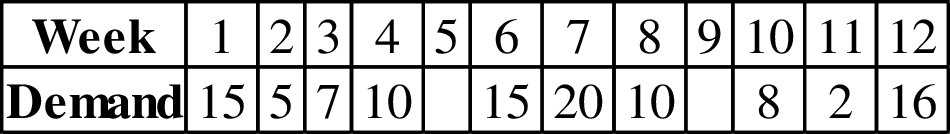

Model 1000 Master Schedule

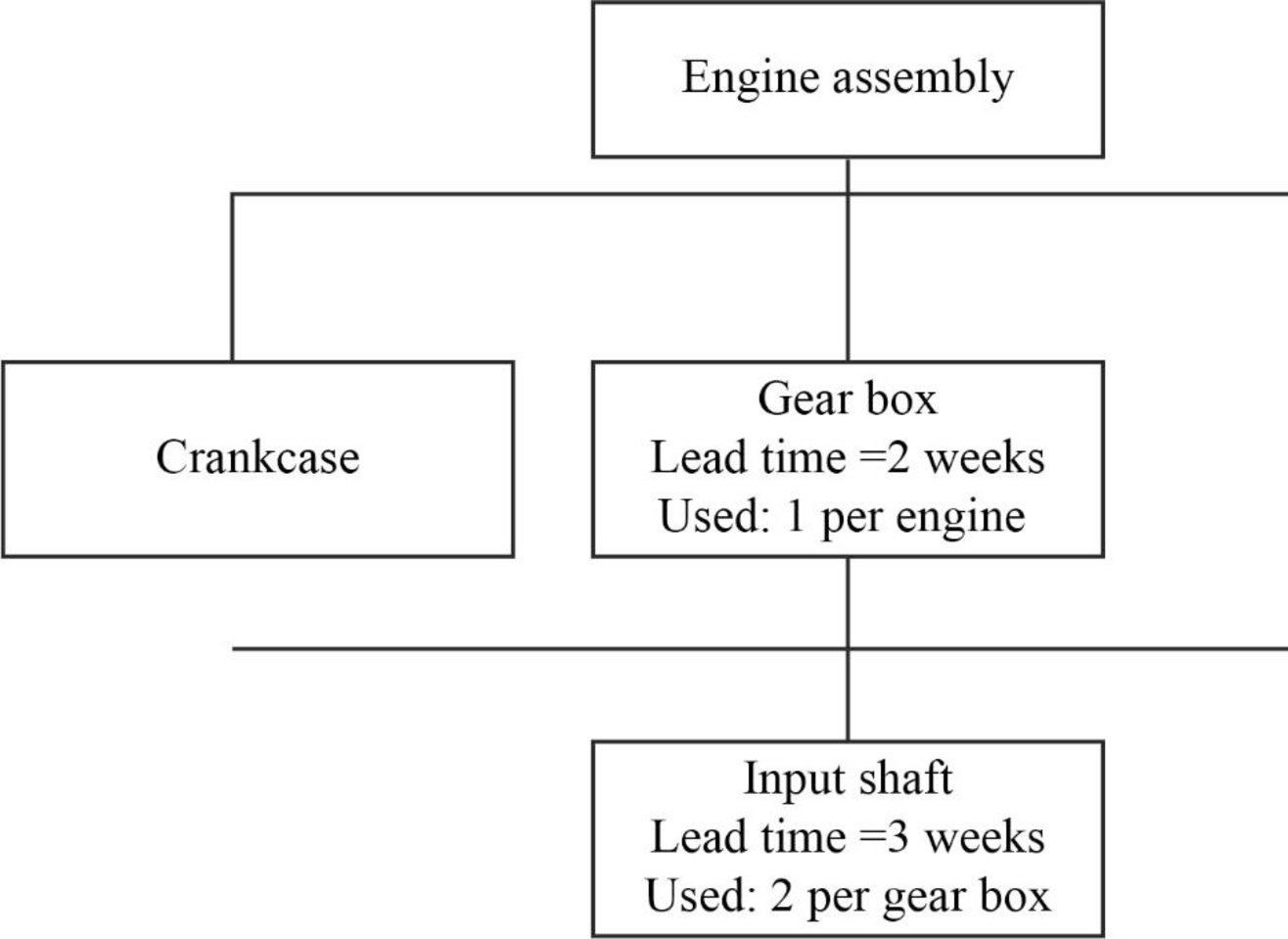

Model 1000 Product Structure

- There are 17 gearboxes on-hand at the beginning of week 1. 5 gearboxes are on order and should be delivered at the beginning of week 2.

- There are 40 input shafts present on-hand at the beginning of week 1, and 22 are scheduled to be delivered at the beginning of week 2.

Cost:

Gearbox:

Setup cost (S) = $90 per order.

Inventory carrying cost (I) = $2 per unit per week.

Input shaft:

Setup cost (S) = $45 per order.

Inventory carrying cost (I) = $1 per unit per week.

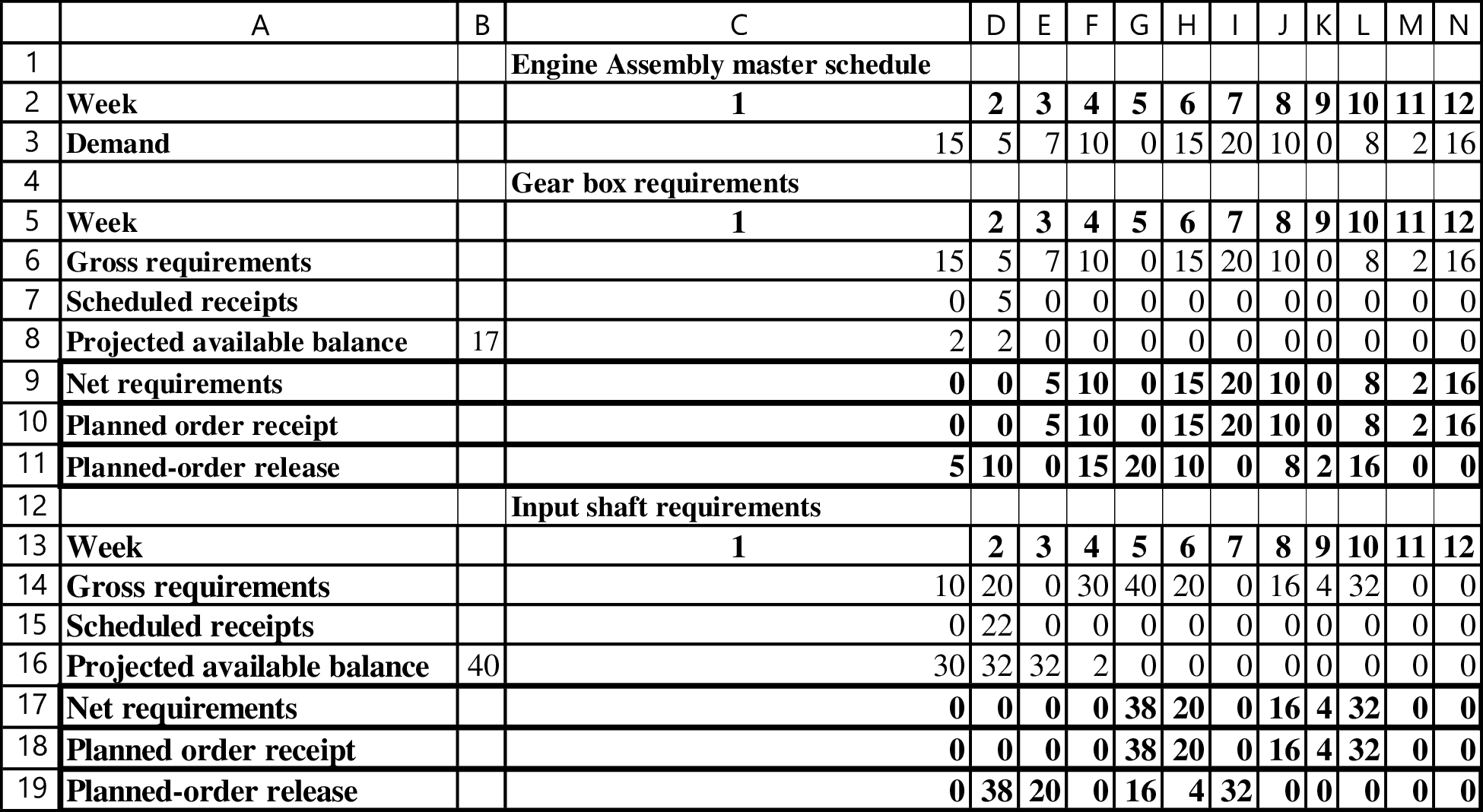

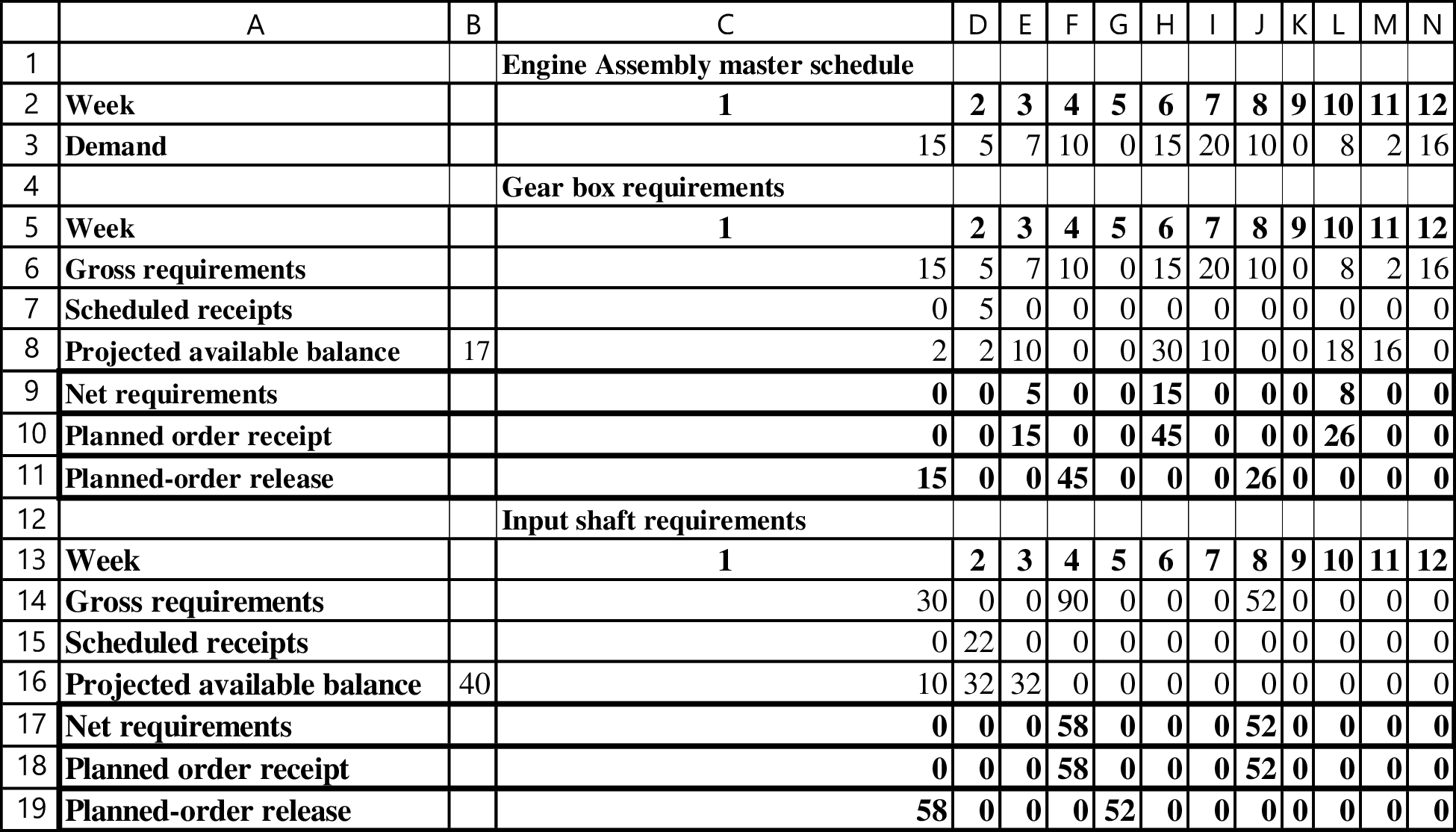

Existing schedule:

Each gearbox will require two units of the input shaft. Hence, the planned order release of the gearbox is doubled when they become the gross requirements of the input shaft.

Calculation of cost of the schedule:

Gearbox:

There are 8 planned order releases. The inventory is 2 units in week 1 and 2 units in week 2. Therefore, the total cost would be:

Input shaft:

There are 5 planned order releases. The inventory is 30 units in week 1, 32 units in week 2, 32 units in week 3, and 2 units in week 4. Therefore, the total cost would be:

The total cost of the schedule would be:

The cost of the existing schedule is $1,049.

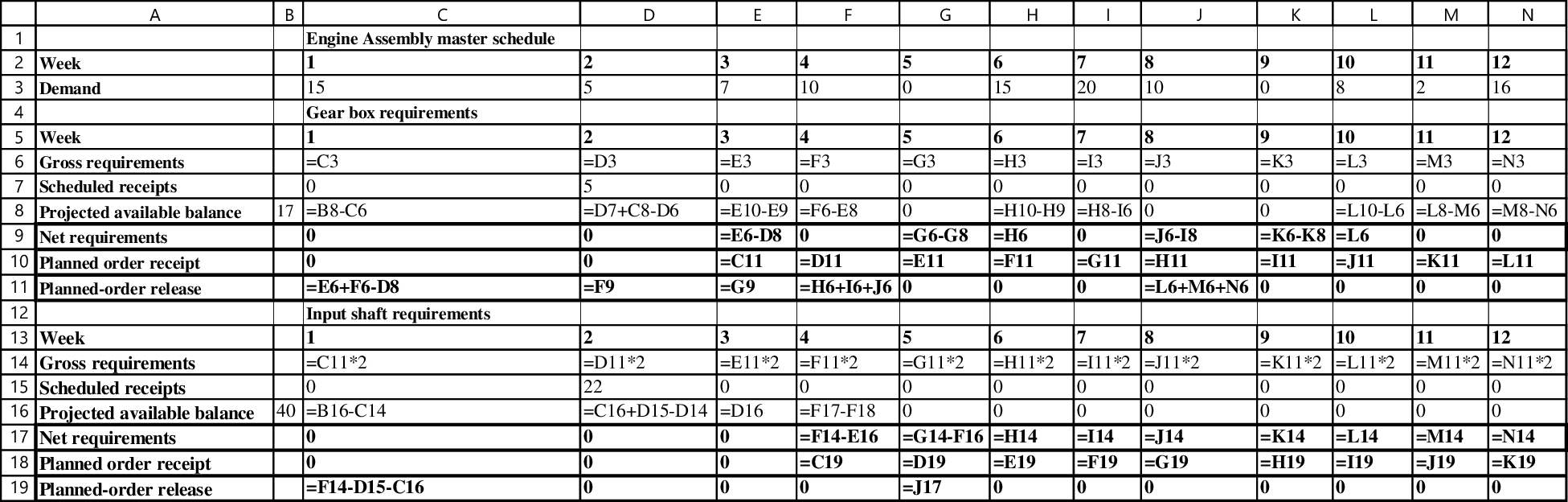

Calculation of net requirements and planned order release for the new schedule:

In order to reduce the number of orders, the planned order releases of three weeks are combined together and released with a lead time of 2 weeks while carrying some amount of inventory.

Formula:

Calculation of cost of the schedule:

Gearbox:

There are 3 planned order releases. The inventory is 2 units in week 1, 2 units in week 2, 10 units in week 3, 30 units in week 6, 10 units in week 7, 18 units in week 11, and 16 units in week 12. Therefore, the total cost would be:

Input shaft:

There are 2 planned order releases. The inventory is 10 units in week 1, 32 units in week 2, and 32 units in week 3. Therefore, the total cost would be:

The total cost of the schedule would be:

The cost of the new schedule is $610.

Calculation the cost difference between the two schedules:

The cost savings with the new schedule is $439.

Want to see more full solutions like this?

Chapter 21 Solutions

Operations and Supply Chain Management (Mcgraw-hill Education)

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.