Applied Statics and Strength of Materials (6th Edition)

6th Edition

ISBN: 9780133840544

Author: George F. Limbrunner, Craig D'Allaird, Leonard Spiegel

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Textbook Question

Chapter 17, Problem 17.3P

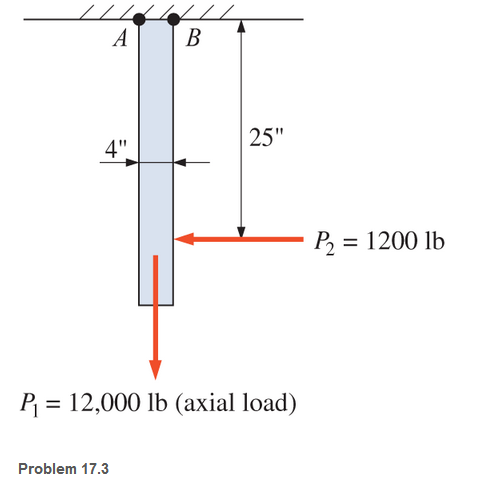

A 1-in.-by-4-in, steel bar is subjected to the loads shown. Calculate the combined stresses at points A and B.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

The vertical load P acting on the wheel of a traveling crane is 13,000 lb. What is the average shear stress in the 1.25 in. diameter axle?

3. Calculate the contact stress between a 100-mm-

diameter steel ball weighing 500 g sitting on a

hardened steel surface plate.

) A machine having a mass of 9555 kg is supported by three solid steelrods arranged as showed in the following figure. Each rod has a diameter of 50 mm. Compute the stresses in MPa in the three rods of AB, BC, and BD.

Chapter 17 Solutions

Applied Statics and Strength of Materials (6th Edition)

Ch. 17 - Prob. 17.1PCh. 17 - A horizontal 30-ft simple span beam is supported...Ch. 17 - A 1-in.-by-4-in, steel bar is subjected to the...Ch. 17 - A W410100 structural steel wide-flange section is...Ch. 17 - A W1272 structural steel wide-flange section is...Ch. 17 - A solid steel shaft 3 in. in diameter and 4 ft...Ch. 17 - A short compression member is subjected to a...Ch. 17 - With reference to Problem 17.7, calculate the...Ch. 17 - A section of a 51-mm-diameter standard-weight...Ch. 17 - For the pipe of Problem 17.9, compute the maximum...

Ch. 17 - A concrete pedestal is in the shape of a cube and...Ch. 17 - 17.12 For the pedestal of Problem 17.11, assume...Ch. 17 - 17.13 Rework Problem 17.11, but assume that the...Ch. 17 - A 12-in-square concrete pedestal is subjected to a...Ch. 17 - 17.15 A short compression member is subjected to a...Ch. 17 - A rectangular concrete footing, 4 ft by 8 ft in...Ch. 17 - The bending and shear stresses developed at a...Ch. 17 - Stresses developed at a point in a machine part...Ch. 17 - Calculate the principal stresses at points A and B...Ch. 17 - 17.20 Rework Problem 17.19 using P = 8000 lb and...Ch. 17 - 17.21 A 1-in.-square steel bar is subjected to an...Ch. 17 - 17.22 A bar having a cross-sectional area of 6...Ch. 17 - Rework Problem 17.22, changing the load to a...Ch. 17 - Solve Problem l7.17 using Mohr’s circle.Ch. 17 - For the elements shown in Problem 17.18, use...Ch. 17 - Solve Problem 17.19 using Mohr’s circle.Ch. 17 - In Problem 17.19, change the load to 8000 lb and...Ch. 17 - For the following computer problems, any...Ch. 17 - For the following computer problems, any...Ch. 17 - For the following computer problems, any...Ch. 17 - For the following computer problems, any...Ch. 17 - A 4-in.-by-8-in. (S4S) Douglas fir timber beam is...Ch. 17 - A horizontal flexural member (a girt) in the wall...Ch. 17 - A simply supported W1850 structural steel...Ch. 17 - A steel link in a machine is designed to avoid...Ch. 17 - 17.36 An 8-in-square (S4S) vertical timber post is...Ch. 17 - A short 3-in.-square steel bar with a...Ch. 17 - A timber member 150 mm by 250 mm (S4S) is loaded...Ch. 17 - A concrete wall 8 ft high and 3 ft thick is...Ch. 17 - 17.40 A short compression member is subjected to a...Ch. 17 - 17.41 Calculate the maximum eccentric load that...Ch. 17 - A short compression member is subjected to two...Ch. 17 - 17.43 Calculate the force P that may be applied to...Ch. 17 - 17.44 A load of 1000 lb is supported on a...Ch. 17 - 17.45 A short compression member is subjected to...Ch. 17 - 17.46 A structural steel wide-flange section is...Ch. 17 - 17.47 A cast-iron frame for a piece of industrial...Ch. 17 - 17.48 The assembly shown is used in a machine. It...Ch. 17 - 17.49 A 50-mm-diameter solid steel shaft is...Ch. 17 - An element of a machine member is subjected to the...Ch. 17 - 17.51 A short-span cantilever built-up beam has...Ch. 17 - Solve Problem 17.50 using Mohr’s circle.Ch. 17 - 17.53 A cantilever beam is subjected to an...Ch. 17 - A 6-in.-diameter solid shaft is subjected to a...Ch. 17 - Rework parts (b) and (c) of Example 17.7 using...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A 15 in diameter rod is subjected to an axial tensile load of 45 kips. Compute. a. The normal stress developed on an inclined plane at an angle of 60° with the cross section of the rod. b. The maximum normal stress developed in the rod.arrow_forwardA 6" diameter pulley attached to a 1" diameter shaft of 2" length is supporting a load of 2000 lb. Determine the location of the highest stresses in the 1" diameter shaft and calculate principal stresses at that point.arrow_forwardA circular rod with a diameter of 40.0 mm has a groove cut to a diameter of 35 mm. A full radius of 3.0 mm is produced at the bottom of the groove. Compute the maximum stress in the rod when an axial tensile force of 46 kN is applied.arrow_forward

- The four bars shown have the same cross-sectional area. For the given loadings, show that (a) the maximum compressive stresses are in the ratio 4:5:7:9, (b) the maximum tensile stresses are in the ratio 2:3:5:3. (Note: the cross section of the triangular bar is an equilateral triangle.)arrow_forwardA steel rod 20 mm in diameter passes centrally through a steel tube of 25 mm internal diameter and 30 mm external diameter. The tube is 800 mm long and is closed by rigid washers of negligible thickness which are fastened by nuts threaded on the rod. The nuts are tightened until the compressive load on the tube is 20 kN. Calculate the stresses in the tube and the rod.Find the increase in these stresses when one nut is tightened by one-quarter of a turn relative to the other. There are 4 threads per 10 mm. Take E = 2 x 105 N/mm2.arrow_forwardAn iron column of annular cross-section has an outer diameter of 200 mm and is subjected to a force of 75 kN. Find the thickness of the wall if the allowable compressive stress is 10 Mpa.arrow_forward

- The structure shown below is hinged to fixed supports at A and C. The bars are each 4 in. by 4 in. in section. Compute the maximum tensile stress developed in bar CB assuming the pin connections at A, B, and C are frictionless. 800 lb 5 ft 5 ft C 500 lb 8 ft 6 ft 2 ft -arrow_forwardThe internal drag truss for the wing of a light airplane is subjected to the forces shown. Determine the stress in members EF, GF and CG. The crossectional area of the truss member is a semi circle with a radius of 1.5 in.arrow_forwardA simplified model of a basketball hoop is shown. During a basket dunk a player hangs from the rim applying a force of 320 lbs including a dynamic load factor. The stand is a square tube with 5 inches outside length and 0.25 inches thickness. The distance from the edge of the rim to the middle of the square tube is 4 ft. Assuming the model is rigid, the normal stress at point A is most closely equal to: a. 1284 psi b. 1248 psi c. 1212 psi d. 36 psi Aarrow_forward

- A cylindrical pressure vessel is designed using steel plating with a thickness equivalent to 15 mm. The inside diameter is 460 mm and its height is 2.5-m. Solve for the maximum internal pressure that can be implied if the longitudinal stress is only up to 120 MPa, while the tangential stress is only up to 50 MPa.arrow_forwardThe bent pipe has a 1.5-in. outer diameter and a 0.2-in. wall thickness. Calculate the largest shear stress that occurs in (a) segment BC; and (b) segment AB. Neglect the stress due to the transverse shear force.arrow_forward5. A load of 5 kN is to be raised by means of a steel wire. Find the minimum diameter required, if the stress in the wire is not to exceed 100 N/mm2.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY

Differences between Temporary Joining and Permanent Joining.; Author: Academic Gain Tutorials;https://www.youtube.com/watch?v=PTr8QZhgXyg;License: Standard Youtube License