Operations Management: Sustainability and Supply Chain Management (12th Edition)

12th Edition

ISBN: 9780134130422

Author: Jay Heizer, Barry Render, Chuck Munson

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 14, Problem 29P

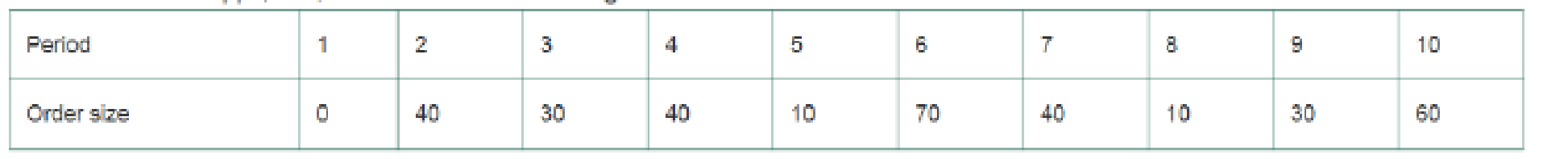

Karl Knapps, Inc., has received the following orders:

The entire fabrication for these units is

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

Coleman Rich, Ltd., has received the followingorders:Period 1 2 3 4 5 6 7 8 9 10Order size 60 30 10 40 70 10 40 30 40 0The entire fabrication for these units is scheduled on one machine.There are 2,250 usable minutes in a week, and each unit will take

65 minutes to complete. Develop a capacity plan, using lot split-ting, for the 10-week time period.

An assembly plant for the Blood Pressure RX, a portable blood pressure device, has

400

minutes available daily in the plant for the device, and the average demand is

80

units per day. Final assembly requires 6 separate tasks. Information concerning these tasks is given in the following table.

Task

Performance Time (minutes)

Task Must Follow Task Listed Below

A

4

-

B

1

-

C

1

A, B

D

3

C

E

4

D

F

2

E

b) Given the demand, what is the cycle time for this operation?

The cycle time for this operation is

enter your response here

minutes/unit (enter your response as a whole number).

c) What is the theoretical minimum number of workstations?

The theoretical minimum number of workstations is

enter your response here

stations (enter your response as a whole number and, if your unrounded answer includes decimal values,…

Describe the techniques to deal with bottleneck operations and some of those techniques that does not decrease throughput time ?

Chapter 14 Solutions

Operations Management: Sustainability and Supply Chain Management (12th Edition)

Ch. 14 - What is the difference between a gross...Ch. 14 - Prob. 2DQCh. 14 - What are the similarities between MRP and DRP?Ch. 14 - How does MRP II differ from MRP?Ch. 14 - Which is the best lot-sizing policy for...Ch. 14 - What impact does ignoring carrying cost in the...Ch. 14 - MRP is more than an inventory system; what...Ch. 14 - What are the options for the production planner...Ch. 14 - Master schedules are expressed in three different...Ch. 14 - What functions of the firm affect an MRP system?...

Ch. 14 - Prob. 11DQCh. 14 - Identify five specific requirements of an...Ch. 14 - What are the typical benefits of ERP?Ch. 14 - What are the distinctions between MRP, DRP, and...Ch. 14 - As an approach to inventory management, how does...Ch. 14 - What are the disadvantages of ERP?Ch. 14 - Use the Web or other sources to: a. Find stories...Ch. 14 - Prob. 18DQCh. 14 - Use the Web or other sources to identify what an...Ch. 14 - You have developed the following simple product...Ch. 14 - You are expected to have the gift bags in Problem...Ch. 14 - Prob. 3PCh. 14 - Prob. 4PCh. 14 - The demand for subassembly S is 100 units in week...Ch. 14 - Using the information in Problem 14.3, construct a...Ch. 14 - Using the information in Problem 14.3, construct a...Ch. 14 - Refer again to Problems 14.3 and 14.4. In addition...Ch. 14 - Refer again to Problems 14.3 and 14.5. In addition...Ch. 14 - a. Given the product structure and master...Ch. 14 - Prob. 11PCh. 14 - Based on the data in Figure 14.13, complete a net...Ch. 14 - Prob. 13PCh. 14 - A part structure, lead time (weeks), and on-hand...Ch. 14 - You are product planner for product A (in Problem...Ch. 14 - Prob. 16PCh. 14 - Prob. 17PCh. 14 - Data Table for Problems 14.17 through 14.20 14.17...Ch. 14 - Develop an EOQ solution and calculate total...Ch. 14 - Develop a POQ solution and calculate total...Ch. 14 - Using your answers for the lot sizes computed in...Ch. 14 - Prob. 26PCh. 14 - Grace Greenberg, production planner for Science...Ch. 14 - Karl Knapps, Inc., has received the following...Ch. 14 - Coleman Rich, Ltd., has received the following...Ch. 14 - Prob. 31PCh. 14 - Using the data for the coffee table in Problem...Ch. 14 - When 18,500 Orlando Magic Fans Come to Dinner...Ch. 14 - When 18,500 Orlando Magic Fans Come to Dinner...Ch. 14 - When 18,500 Orlando Magic Fans Come to Dinner...Ch. 14 - MRP at Wheeled Coach Video Case Wheeled Coach, the...Ch. 14 - MRP at Wheeled Coach Video Case Wheeled Coach, the...Ch. 14 - MRP at Wheeled Coach Video Case Wheeled Coach, the...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Explain the techniques to deal with bottleneck operations and some of those techniques that does not decrease throughput time ?arrow_forwardBalance the assembly line using Ranked Positional Weight method using the data in Table 2 and determine the idle time at each station. The cycle time for meeting the demand is 38 minutes. тable 2 Time Immediate Operation (min) predecessor A B 3 C 10 А, В D 13 E 19 24 22 16arrow_forwardAnswer both clearlyarrow_forward

- A firm that produces electric golf carts has just received an order for 200 carts, which must be ready for delivery at the start of week 8. Information concerning the product structure, lead times, and quantities on hand is shown in the following table. Use this information to do each of the following: a. Construct an assembly time chart in Excel.arrow_forwardFor manufacturing electric bus Total labor hours, estimation process, and summary resultsarrow_forwardYou've just been assigned the job of setting up an electric fan assembly line with the following tasks and precedence relationships The assemtly line wil be nunning 8 hours per day and 5 days per week, The demand forast is 600 Items per week. Your goal is to minimie the numbor of workstations necesary to complete enough units to satisfy the demand forecast. What is the takt time (in minutes) needed to produce the required number of units? (Integer Answer, do not put anything other than numbers.) What is the theoretical minimum number of workstations that you will need (apply the round-up rule)? (Integer Answer, do not put anything other than numbers.)arrow_forward

- Product A is assembled from one B and two C’s. Each itemrequires one or more operations, as indicated by the circles in the product structure diagram. Assume lead time is neg-ligible. From the information given: a. Develop a load profile chart for each of the three workcenters.b. Level the loads. Discuss possible consequences ofshifting work to other periods.arrow_forwardManufacturing Company uses FIFO method of accumulating costs in a two-department process. Materials are introduced at the inception of the process except for a special material which is added in department 2 at 60% completion as to overhead. Inspection is done at the end of the process in both departments. Production data for Department 2 are given below: In process, beginning, (80% labor, 70% overhead)2,000 Transferred in 14,900 In process, ending (40% labor, 20% overhead) 3,000 Normal spoilage 200 Abnormal spoilage (found at 30% completion as to laborand 15% as to overhead due to internal failure) 400 Cost data for the month:In process beginning:Transferred in 15,020 Special materials 1,900 Direct labor 4,388 Overhead 11,044 Current costs:Transferred in 137,080 Special materials 14,030 Direct labor 46,000 Overhead 113,564 The cost of units transferred to finished goods is?The cost of spoilage charged to revenue is?arrow_forwardWhich operation is the bottleneck of this process? a. Stocking b. Pricing c. Spotting d. Shipping e. Impossible to determinearrow_forward

- Describe the inputs, outputs, and nature of MRP processing.arrow_forwardSunspot Beverages, Ltd., of Fiji uses the weighted-average method in its process costing system. It makes blended tropical fruit drinks in two stages. Fruit juices are extracted from fresh fruits and then blended in the Blending Department. The blended juices are then bottled and packed for shipping In the Bottling Department. The following Information pertalns to the operations of the Blending Department for June. Percent Completed Materials Conversion Work in process, beginning Started into production Completed and transferred out Work in process, ending Units 104,000 494,500 484,500 114,000 70% 40% 75% 25% Materials Conversion Work in process, beginning Cost added during June $ 44,300 S 16,300 $ 474,400 $ 347,930 Requlred: 1. Calculate the Blending Department's equivalent units of production for materials and conversion in June. 2. Calculate the Blending Department's cost per equivalent unit for materials and conversion in June. 3. Calculate the Blending Department's cost of ending…arrow_forwardWhat are advantages and disadvantages of work cells? What is a heuristic? Name several that can be used in assembly-line balancing.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY