Concept explainers

a)

To determine: The Economic order quantity.

Introduction: Inventory management is the process of ordering, storing and using inventory of the company such raw material, components and finished goods. It governs the flow of goods from manufacturers to warehouse and to the point of sale. The key function is to maintain record of flow of new or returned products which enters or leaves the company.

a)

Answer to Problem 28P

The economic order quantity for vendor A is 336.07 units and for vendor B is 335.08 units.

Explanation of Solution

Given information:

| Vendor 1 | |

| Quantity | Price |

| 1-499 | $17.00 |

| 500-999 | $16.75 |

| 1,000+ | $16.50 |

| Vendor 2 | |

| 1-399 | $17.10 |

| 400-799 | $16.85 |

| 800-1,199 | $16.60 |

| 1,200+ | $16.25 |

Formula:

Where

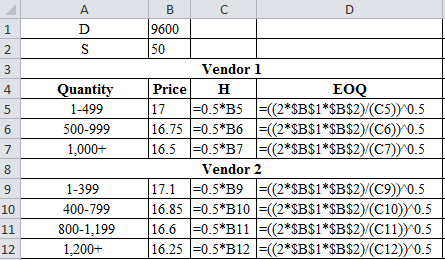

Calculation of Economic order quantity:

For vendor 1 with quantity 1-499:

EOQ is calculated by multiplying 2, 9600 and 50 and dividing the resultant

Same calculation procedure follows for the rest of the quantities and the result is,

| D | 9600 | ||

| S | $50.00 | ||

| Vendor 1 | |||

| Quantity | Price | H | EOQ |

| 1-499 | $17.00 | $8.50 | 336.07 |

| 500-999 | $16.75 | $8.38 | 338.57 |

| 1,000+ | $16.50 | $8.25 | 341.12 |

| Vendor 2 | |||

| 1-399 | $17.10 | $8.55 | 335.08 |

| 400-799 | $16.85 | $8.43 | 337.56 |

| 800-1,199 | $16.60 | $8.30 | 340.09 |

| 1,200+ | $16.25 | $8.13 | 343.74 |

Working:

Based on the above calculation, the EOQ for vendor A is 336.07 units and for vendor B is 335.08 units.

Hence, the economic order quantity for vendor A is 336.07 units and for vendor B is 335.08 units.

b)

To determine: The quantities to be ordered and supplier to be selected.

b)

Answer to Problem 28P

Vendor 2 should be selected at 1,200 units of ordering quantities

Explanation of Solution

Given information:

| Vendor 1 | |

| Quantity | Price |

| 1-499 | $17.00 |

| 500-999 | $16.75 |

| 1,000+ | $16.50 |

| Vendor 2 | |

| 1-399 | $17.10 |

| 400-799 | $16.85 |

| 800-1,199 | $16.60 |

| 1,200+ | $16.25 |

Formula:

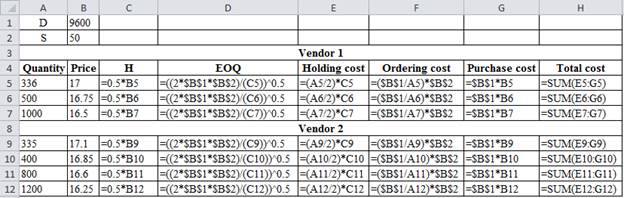

Calculation of ordering quantities:

| D | 9600 | ||||||

| S | $50.00 | ||||||

| Vendor 1 | |||||||

| Quantity | Price | H | EOQ | Holding cost | Ordering cost | Purchase cost | Total cost |

| 336 | $17.00 | $8.50 | 336.07 | $1,428.00 | $1428.6 | $163,200.00 | $166056.57 |

| 500 | $16.75 | $8.38 | 338.57 | $2,093.75 | $960.0 | $160,800.00 | $163853.75 |

| 1000 | $16.50 | $8.25 | 341.12 | $4,125.00 | $480.0 | $158,400.00 | $163005.00 |

| Vendor 2 | |||||||

| 335 | $17.10 | $8.55 | 335.08 | $1,432.13 | $1432.8 | $164,160.00 | $167024.96 |

| 400 | $16.85 | $8.43 | 337.56 | $1,685.00 | $1200.0 | $161,760.00 | $164645.00 |

| 800 | $16.60 | $8.30 | 340.09 | $3,320.00 | $600.0 | $159,360.00 | $163280.00 |

| 1200 | $16.25 | $8.13 | 343.74 | $4,875.00 | $400.0 | $156,000.00 | $161275.00 |

Table 1

Working:

Based on the above calculations it can be inferred that Vendor 2 can be selected because the total cost is least at 1,200 ordering quantities (refer table1).

Hence, vendor 2 should be selected at 1,200 units of ordering quantities.

c)

To determine: The total cost for most economic order quantities.

c)

Answer to Problem 28P

The optimum ordering quantity is 1200 units and total annual cost is $161275.00.

Explanation of Solution

Given information:

| Vendor 1 | |

| Quantity | Price |

| 1-499 | $17.00 |

| 500-999 | $16.75 |

| 1,000+ | $16.50 |

| Vendor 2 | |

| 1-399 | $17.10 |

| 400-799 | $16.85 |

| 800-1,199 | $16.60 |

| 1,200+ | $16.25 |

Calculation of total cost:

Table 1 provides the calculation for total cost.

Hence, the optimum ordering quantity is 1200 units and total annual cost is $161275.00.

d)

To determine: The factors to be considered besides total cost.

d)

Explanation of Solution

Given information:

| Vendor 1 | |

| Quantity | Price |

| 1-499 | $17.00 |

| 500-999 | $16.75 |

| 1,000+ | $16.50 |

| Vendor 2 | |

| 1-399 | $17.10 |

| 400-799 | $16.85 |

| 800-1,199 | $16.60 |

| 1,200+ | $16.25 |

Factors to be considered besides total cost:

Apart from making decision based on total cost some other factor also have to be considered for making decisions to avoid uncertainty. Some other factors like perishability of the chemicals, the environment in which the chemicals are stored, storage space to handle 1,200 pounds of chemical have to be taken into account.

Want to see more full solutions like this?

Chapter 12 Solutions

EBK PRINCIPLES OF OPERATIONS MANAGEMENT

- Economics A hospital uses 18,000 of syringes each year. Holding cost per box is $0.60 ordering costs are $96 per order. The hospital buyer would like to take advantage of quantity discounts offered by the supplier. The cost structure is as follows: Number of boxes Price per box 1,000 to 1,999 $1.25 2,000 to 4,999 $1.20 5,000 to 9,999 $1.15 10,000 or more $1.10 Use this data to answer the following: In what level is the EOQ What is the optimal order quantity? What is total cost at each level after the EOQ level?arrow_forwardChris Sandvig Irrigation, Inc., has summarizedthe price list from four potential suppliers of an undergroundcontrol valve. See the accompanying table. Annual usage is2,400 valves; order cost is $10 per order; and annual inventory holding costs are $3.33 per unit.Which vendor should be selected and what order quantityis best if Sandvig Irrigation wants to minimize total cost?arrow_forwardPHL Manufacturing assembles security monitors. It purchases 900 black-and-white cathode ray tubes per month at $80 each. Ordering costs are $30, and annual carrying costs are 25 percent of the purchase price. - a) Determine the optimal quantity (4 points) - b) Find the total annual cost of ordering and carrying the inventory (2 points) - c) If the supplier offer a price of $79 per tube for ordering 1200 tubes in a lot, would you evaluate and advise PHL to take advantage of the offer?arrow_forward

- . The following table contains figures on the monthly volume and unit costs for a random sample of 16 items from a list of 2,000 inventory items at a health care facility. a-Develop an A-B-C classification for these items. b-Given the monthly usages in the following table, classify the items in A, B, and C categories according to dollar usage. c- Determine the percentage of items in each category and the annual dollar value for each category for part b. The principal table are in the picture belowarrow_forwardChris Sandvig Irrigation, Inc., has summarized the price list from four potential suppliers of an underground control valve. See the table below. Annual usage is 800 valves; order cost is $7 per order; and annual inventory holding costs are $2.15 per unit. D Vendor A units at a time from Vendor C Vendor B Quantity 1-14 15-24 25-99 100-199 200-399 400+ Which vendor should be selected and what order quantity is best if Sandvig Irrigation wants to minimize total cost? Chris Sandvig Irrigation should order (enter your response as a whole number). Vendor A Price $35.00 34.75 33.55 32.35 31.15 30.75 Vendor D Vendor B Quantity 1-24 25-99 100-199 200-399 400+ Price $34.75 34.00 32.80 31.60 30.50 Vendor C Quantity 1-49 50-149 150-299 300+ Price $34.50 33.75 32.50 31.10 Vendor D Quantity 1-149 150-299 300+ Price $34.25 33.00 31.00arrow_forwardYour company has the following items in inventory: Unit Cost $9 $90 $6 Item A B с D E F G H Annual Demand 1200 100 4500 400 35 250 1000 100 $150 $2000 $120 $90 $75 a) What is the annual dollar volume for all items b) Perform an ABC analysis on the data. Which are the A items, the B items and the C item: c) Why is it desirable to classify items into groups, as the ABC classification scheme does? d) Define and discuss the term "productivity" with help of productivity equation.arrow_forward

- Disscus benefits and risks of aggreting inventory in the supply chain . Include in the disscution an explanation of how inventory aggretion may change the structure of the supply chain.arrow_forwardBarangay Punta Princesa is trying to decide between two alternative order plans for its inventory of face masks. Irrespective of the plan to be followed, demand for the item is expected to be 1,000 units annually. Under Plan A, Barangay Punta Princesa through their purchasing officer is using a digital platform for ordering: order costs would be Php 40 per order. Inventory holding costs (carrying costs) would be Php 100 per unit per annum. Under Plan B order costs would be Php 30 per order. And holding costs would 20% and unit cost is Php 480. Find out EOQ and Total Inventory cost, then come up with your decision which plan would result in the lowest total inventory cost?arrow_forwardEmery Pharmaceutical uses an unstable chemical compound that must be kept in an environment where both temperature and humidity can be controlled. Emery uses 200 pounds per month of the chemical, estimates the holding cost to be £3.33 (because of spoilage), and estimates order costs to be £10 per order. What quantity should be ordered, and which supplier should be used? Discuss factor(s) should be considered besides total cost.arrow_forward

- can someone help me with this question? Oleg Blokhin Sportwear uses, for the goalkeeper gloves, a time sensitive and unstable chemical compound that must be kept in an environment where both temperature and humidity can be controlled. He uses 250 pounds per month of the chemical, estimates the holding cost to be £4.25 (because of spoilage), and estimates order costs to be £20 per order. The cost schedules of four suppliers are as follows: (the image) for the first part: Identify and discuss what quantity should be ordered, and which supplier should be used? quantitative answer. please show step by step calculation so i know what you did to get answer. you can type it - no need for writing it. now for anther question: Discuss factor(s) that should be considered besides total. thank you very much:)arrow_forwardDescribe how are reorder point & lead time interrelated in inventory analysis?arrow_forwardBarangay Punta Princesa is trying to decide between two alternative order plans for its inventory of face masks. Irrespective of the plan to be followed, demand for the item is expected to be 1,000 units annually. Under Plan A, Barangay Punta Princesa through their purchasing officer is using a digital platform for ordering: order costs would be Php 40 per order. Inventory holding costs (carrying costs) would be Php 100 per unit per annum. Under Plan B order costs would be Php 30 per order. And holding costs would 20% and unit cost is Php 480. Find out EOQ and Total Inventory cost, then come up with your decision which plan would result in the lowest total inventory cost? can you answer this asap?arrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning