Concept explainers

(a)

Interpretation: Total annual logistics cost needs to be calculated based on the given data.

Concept Introduction: Total supply chain cost is a vital measure of performance of any supply chain and it includes all related costs incurred in the supply chain.

(a)

Explanation of Solution

Given Information:

| Alpha Medical Manufacturing (AMM) outsourcing information for a surgical screw | |||||||

| Contract Manufacturer (Tier 1 supplier) | Price per unit @ Q = 10,000 (C) | Price per unit @ Q = 20,000 (C) | Tariff cost (Ti) per unit | Transport mode cost (Tm) per unit | Order Costs (Co) | Cost to store one unit per year (Ch) | Order Lead Time in Days |

| Xiajing Supplier | $ 1.10 | $0.92 | $0.2 | $0.35 | $ 655 | $ 1.35 | 180 |

| Boston Medical Supplier | $ 1.25 | $1.15 | $0.00 | $0.15 | $ 260 | $ 1.00 | 90 |

| Werkzeug Supplier | $ 1.35 | $1.00 | $0.10 | $0.20 | $ 350 | $ 1.05 | 120 |

Annual Demand (D) = 20,000 units

Working days − 365 days in a year

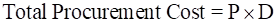

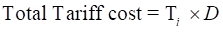

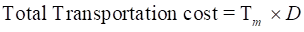

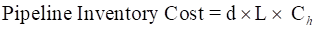

Total Annual Logistic cost can be calculated using following formula:

Total Annual Logistic Cost (TALC) = Total Procurement cost + Total Tariff cost + Total Transportation cost + Total Order Cycle inventory cost + Total Pipeline inventory cost

Where,

D = Annual Demand

Q = Order Quantity

Co = Ordering Cost

Ch= Inventory holding cost

d = Average Daily demand

L = Lead time

For Order quantity of 10,000 units

| Alpha Medical Manufacturing (AMM) outsourcing information for a surgical screw | |||||||

| Contract Manufacturer (Tier 1 supplier) | Total Procurement Cost | Total Tariff Cost ($) | Total Transport Cost ($) | Order Cycle Inventory Cost ($) | Pipeline Inventory Cost ($) | Total Annual Logistic Cost ($) | |

| Xiajing Supplier | 22,000 | 4,000 | 7,000 | 1,310 | 13,315.06 | 47625.06 | |

| Boston Medical Supplier | 25,000 | 0 | 3,000 | 520 | 4,931.5 | 33451.5 | |

| Werkzeug Supplier | 27,000 | 2,000 | 4,000 | 700 | 69,041.09 | 102741.09 | |

For Order quantity of 20,000 units

| Alpha Medical Manufacturing (AMM) outsourcing information for a surgical screw | |||||||

| Contract Manufacturer (Tier 1 supplier) | Total Procurement Cost | Total Tariff Cost ($) | Total Transport Cost ($) | Order Cycle Inventory Cost ($) | Pipeline Inventory Cost ($) | Total Annual Logistic Cost ($) | |

| Xiajing Supplier | 22,000 | 4,000 | 7,000 | $ 655 | 13,315.06 | 46970.06 | |

| Boston Medical Supplier | 25,000 | 0 | 3,000 | $ 260 | 4,931.5 | 33,191.5 | |

| Werkzeug Supplier | 27,000 | 2,000 | 4,000 | $ 350 | 69,041.09 | 102,391.09 | |

| Alpha Medical Manufacturing (AMM) outsourcing information for a surgical screw | |||||||

| Contract Manufacturer (Tier 1 supplier) | Total Procurement Cost | Total Tariff Cost ($) | Total Transport Cost ($) | Order Cycle Inventory Cost ($) | Pipeline Inventory Cost ($) | Total Annual Logistic Cost ($) | |

| Xiajing Supplier | 22,000 | 4,000 | 7,000 | $ 655 | 13,315.06 | 46970.06 | |

| Boston Medical Supplier | 25,000 | 0 | 3,000 | $ 260 | 4,931.5 | 33,191.5 | |

| Werkzeug Supplier | 27,000 | 2,000 | 4,000 | $ 350 | 69,041.09 | 102,391.09 | |

Total Annual Logistics Cost of each supplier at different order quantity will be

| Total Annual Logistic Cost | Order Quantity (Q) | |

| 10,000 units | 20,000 units | |

| Xiajing Supplier | $ 47,625.06 | $ 46,970.06 |

| Boston Medical Supplier | $ 33,451.5 | $ 33,191.5 |

| Werkzeug Supplier | $ 102,741.09 | $ 102,391.09 |

(b)

Interpretation: Recommendation needs to be given based on the given data.

Concept Introduction: Total supply chain cost is a vital measure of performance of any supply chain and it includes all related costs incurred in the supply chain.

(b)

Explanation of Solution

As per the data calculated in above part,

Boston Medical Supplier should be recommended as it has low total annual logistic cost at both order quantities.

(c)

Interpretation: Recommendation needs to be given based on the given data.

Concept Introduction: Total supply chain cost is a vital measure of performance of any supply chain and it includes all related costs incurred in the supply chain.

(c)

Explanation of Solution

Company should also look for quality parameters that will affect product sales and rate the vendors accordingly before making the final supplier decision.

Company should also consider the management oversight cost and calculate the overall supply chain cost at economic order quantity in order to make a balanced supply chain decision.

Want to see more full solutions like this?

- Scenario 3 Ben Gibson, the purchasing manager at Coastal Products, was reviewing purchasing expenditures for packaging materials with Jeff Joyner. Ben was particularly disturbed about the amount spent on corrugated boxes purchased from Southeastern Corrugated. Ben said, I dont like the salesman from that company. He comes around here acting like he owns the place. He loves to tell us about his fancy car, house, and vacations. It seems to me he must be making too much money off of us! Jeff responded that he heard Southeastern Corrugated was going to ask for a price increase to cover the rising costs of raw material paper stock. Jeff further stated that Southeastern would probably ask for more than what was justified simply from rising paper stock costs. After the meeting, Ben decided he had heard enough. After all, he prided himself on being a results-oriented manager. There was no way he was going to allow that salesman to keep taking advantage of Coastal Products. Ben called Jeff and told him it was time to rebid the corrugated contract before Southeastern came in with a price increase request. Who did Jeff know that might be interested in the business? Jeff replied he had several companies in mind to include in the bidding process. These companies would surely come in at a lower price, partly because they used lower-grade boxes that would probably work well enough in Coastal Products process. Jeff also explained that these suppliers were not serious contenders for the business. Their purpose was to create competition with the bids. Ben told Jeff to make sure that Southeastern was well aware that these new suppliers were bidding on the contract. He also said to make sure the suppliers knew that price was going to be the determining factor in this quote, because he considered corrugated boxes to be a standard industry item. Is Ben Gibson acting legally? Is he acting ethically? Why or why not?arrow_forwardScenario 3 Ben Gibson, the purchasing manager at Coastal Products, was reviewing purchasing expenditures for packaging materials with Jeff Joyner. Ben was particularly disturbed about the amount spent on corrugated boxes purchased from Southeastern Corrugated. Ben said, I dont like the salesman from that company. He comes around here acting like he owns the place. He loves to tell us about his fancy car, house, and vacations. It seems to me he must be making too much money off of us! Jeff responded that he heard Southeastern Corrugated was going to ask for a price increase to cover the rising costs of raw material paper stock. Jeff further stated that Southeastern would probably ask for more than what was justified simply from rising paper stock costs. After the meeting, Ben decided he had heard enough. After all, he prided himself on being a results-oriented manager. There was no way he was going to allow that salesman to keep taking advantage of Coastal Products. Ben called Jeff and told him it was time to rebid the corrugated contract before Southeastern came in with a price increase request. Who did Jeff know that might be interested in the business? Jeff replied he had several companies in mind to include in the bidding process. These companies would surely come in at a lower price, partly because they used lower-grade boxes that would probably work well enough in Coastal Products process. Jeff also explained that these suppliers were not serious contenders for the business. Their purpose was to create competition with the bids. Ben told Jeff to make sure that Southeastern was well aware that these new suppliers were bidding on the contract. He also said to make sure the suppliers knew that price was going to be the determining factor in this quote, because he considered corrugated boxes to be a standard industry item. As the Marketing Manager for Southeastern Corrugated, what would you do upon receiving the request for quotation from Coastal Products?arrow_forwardOutline the importance of random supplier visits.arrow_forward

- List and discuss potential supply chain modeling pitfalls to avoid.arrow_forwardWorks Inc. designs industrial tooling parts and makes the molds for those parts. The following activities take place when the company creates a new mold. Classify each cost as unit level (U), batch level (B), product/process level (P), or organizational level (O). Consultation with equipment manufacturer on design specifications Engineering design of mold Creating mold Moving materials from warehouse for test quantity Direct materials for test quantity to judge conformity to design specifications Inspecting test quantity Preparing design specification changes based on test molds Depreciating small kiln used solely for test quantities Depreciating manufacturing buildingarrow_forward12. Supply chain is a system of organizations, people, activities, data and properties involved in moving a productor service from supplier to customer. A. True B. Falsearrow_forward

- Discuss the ethical considerations surrounding the sourcing of rare minerals and materials used in mobile device manufacturing.arrow_forwardDescribe the role of VLANs in Quality of Service (QoS) implementation.arrow_forwardPrepare a short research paper explaining how to source computer chips which will be used in the manufacturing of the computers for your company who is planning to build them in China. Be sure to explain the entire sourcing and qualification process necessary in developing the entire Supply Chain. Explain the key factors involved and how they will impact your operations. Identify all companies you will be considering as vendors and explain why their selection. The paper should be double spaced in MLA format and contain at least 2 academic references not including textbook which can be used as well and as many websites needed, all will need to be MLA format on a separate reference page.arrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning