Materials Science And Engineering Properties

1st Edition

ISBN: 9781111988609

Author: Charles Gilmore

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

6.6.6.6.6

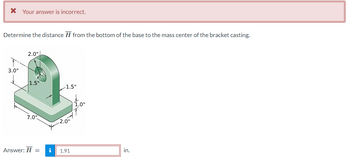

Transcribed Image Text:* Your answer is incorrect.

Determine the distance from the bottom of the base to the mass center of the bracket casting.

3.0"

2.0"

1.5"

1.5"

1.0

7.0"

2.0

1.0"

Answer: H=

= i

1.91

in.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- Refer to Figure P6.4. A strip load of q = 900 lb/ft2 is applied over a width B = 36 ft. Determine the increase in vertical stress at point A located z = 15 ft below the surface. Given: x = 27 ft. Figure P6.4arrow_forwardA W1422 acts compositely with a 4-inch-thick floor slab whose effective width b is 90 inches. The beams are spaced at 7 feet 6 inches, and the span length is 30 feet. The superimposed loads are as follows: construction load = 20 psf, partition load = 10 psf, weight of ceiling and light fixtures = 5 psf, and live load = 60 psf, A992 steel is used, and fc=4 ksi. Determine whether the flexural strength is adequate. a. Use LRFD. b. Use ASD.arrow_forwardDirection: Circle T to indicate true statements or F to indicate false statements. Copper is not a conductor of electricity because only materials that are magnetic can conduct electricity.arrow_forward

- A column in a building is subjected to the following load effects: 9 kips compression from dead load 5 kips compression from roof live load 6 kips compression from snow 7 kips compression from 3 inches of rain accumulated on the roof 8 kips compression from wind a. If lead and resistance factor design is used, determine the factored load (required strength) to be used in the design of the column. Which AISC load combination controls? b. What is the required design strength of the Column? c. What is the required nominal strength of the column for a resistance factor of 0.90? d. If allowable strength design is used, determine the required load capacity (required strength) to be used in the design of the column. Which AISC load combination controls? e. What is the required nominal strength of the column for a safety factor of 1.67?arrow_forwardA tensile test was performed on a metal specimen having a circular cross section with a diameter 0. 510 inch. For each increment of load applied, the strain was directly determined by means of a strain gage attached to the specimen. The results are, shown in Table: 1.5.1. a. Prepare a table of stress and strain. b. Plot these data to obtain a stress-strain curve. Do not connect the data points; draw a best-fit straight line through them. c. Determine the modulus of elasticity as the slope of the best-fit line.arrow_forwardDetermine the smallest value of yield stress Fy, for which a W-, M-, or S-shape from Part 1 of the Manual will become slender. To which shapes does this value apply? What conclusion can you draw from your answer?arrow_forward

- The data in Table 1.5.3 were obtained from a tensile test of a metal specimen with a rectangular cross section of 0.2011in.2 in area and a gage length (the length over which the elongation is measured) of 2.000 inches. The specimen was not loaded to failure. a. Generate a table of stress and strain values. b. Plot these values and draw a best-fit line to obtain a stress-strain curve. c. Determine the modulus of elasticity from the slope of the linear portion of the curve. d. Estimate the value of the proportional limit. e. Use the 0.2 offset method to determine the yield stress.arrow_forwardA tensile test was performed on a metal specimen with a diameter of 1 2 inch and a gage length (the length over which the elongation is measured) of 4 inches. The dam were plotted on a load-displacement graph. P vs. L. A best-fit line was drawn through the points, and the slope of the straight-line portion was calculated to be P/L =1392 kips/in. What is the modulus of elasticity?arrow_forwardUse an elastic analysis and determine the maximum load in the weld (in kips per inch of length).arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Engineering Fundamentals: An Introduction to Engi...Civil EngineeringISBN:9781305084766Author:Saeed MoaveniPublisher:Cengage Learning

Engineering Fundamentals: An Introduction to Engi...Civil EngineeringISBN:9781305084766Author:Saeed MoaveniPublisher:Cengage Learning Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning, Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781305081550Author:Braja M. DasPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781305081550Author:Braja M. DasPublisher:Cengage Learning Architectural Drafting and Design (MindTap Course...Civil EngineeringISBN:9781285165738Author:Alan Jefferis, David A. Madsen, David P. MadsenPublisher:Cengage Learning

Architectural Drafting and Design (MindTap Course...Civil EngineeringISBN:9781285165738Author:Alan Jefferis, David A. Madsen, David P. MadsenPublisher:Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:9781111988609

Author:Charles Gilmore

Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...

Civil Engineering

ISBN:9781337094740

Author:Segui, William T.

Publisher:Cengage Learning

Engineering Fundamentals: An Introduction to Engi...

Civil Engineering

ISBN:9781305084766

Author:Saeed Moaveni

Publisher:Cengage Learning

Solid Waste Engineering

Civil Engineering

ISBN:9781305635203

Author:Worrell, William A.

Publisher:Cengage Learning,

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781305081550

Author:Braja M. Das

Publisher:Cengage Learning

Architectural Drafting and Design (MindTap Course...

Civil Engineering

ISBN:9781285165738

Author:Alan Jefferis, David A. Madsen, David P. Madsen

Publisher:Cengage Learning