Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

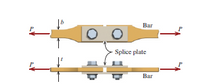

Two flat bars loaded in tension by force P are spliced with

the use of two rectangular splice plates and two 0.375 in. diameter

bolts as shown in Figure P4.3. Away from the connection, the

bars have a width b = 0.625 in. and a thickness t = 0.25 in. The bars

are made of polyethylene having an ultimate tensile strength of

3,100 psi and an ultimate bearing strength of 2,000 psi. The bolts

are made of nylon that has an ultimate shear strength of 4,000 psi.

Determine the allowable load P for this connection if a safety

factor of 3.5 is required. Consider tension and bearing in the bars

and shear in the bolts. Disregard friction between the plates.

Transcribed Image Text:Bar

P.

Splice plate

Bar

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 4. The section of peripheral nerve in neck is under tension of force F=0.18N due to sudden movement that causes large deformation of the nerve. As shown in the below figure, the nerve consists of two structures: fascicles and epineurium with modulus of elasticity of Efascicles=Ef2=MPa and Eepineurium=Ee 0.5MPA. Note: you can model all three fascicles as one part with the cross section of Afascicles=A=3((200×10“)²)= 12 n x10*. Use compatibility condition (fascicles and epineurium deform together) b) Determine the deformation of the peripheral nerve (L=50mm). Note: make sure to include the entire solution including the internal forces in fascicles and/or epineurium. d) If the nerve can tolerate strain up to 0.2, determine if the nerve got injured or not due to this sudden movement Peripheral nerve Under tension AF 50mm Fascicles F 400μm Epineurium 400um 400µm Cross section of peripheral nerve 1000um (Answer: 8 9.4mm )arrow_forwardA stepped bar is fixed at end C. The bar has a cross sectional area of 1000 mm² in AB, and a 2000 mm² cross sectional area in BC. Young's Modulus of the bar's material is 200 GPa. A horizontal force of 100 kN is applied to cross section B. There is a gap b = 0.2mm between right end A and the rigid wall. If the bar is stretched to contact the rigid wall and is welded to it, determine the minimum horizontal force F that needs to be applied to end A. 300 mm 400 mm F A 0.2 mm B 100 KNarrow_forward2. Problem 2: A flat plate, shown below, with a fillet radius of 0.1875 in. is subjected to an axial tension force of 1000 lbs on the right side. The plate is fixed on the left side. The dimension of the plate is given in the figure below and the thickness of the plate is 0.25 in. Note that all dimensions are in inches. It will be faster to model this in Creo Parametric Or Solid Works and then save it as a step file. Material is Structural Steel, same used in the tutorial (RECTANGULAR PLATE WITH CIRCULAR HOLE SUBJECTED TO TENSILE LOADING). 22500 2.25 4.0000 4.00 H PRT_CSYS DEF 0.1875 VPRT CSYS DEF R. 1875 f*f* R₁ 11 10.00 10.0000 3.0000 0.7500 3.0000 -0.7500 1.5000 $ 1.50arrow_forward

- Q2) A plate clutch has 3 discs on the driving shaft and 2 discs on the driven shaft providing 4 pairs of contact surfaces (8 contact surfaces) each of 240 mm external diameter and 120 mm internal diameter. Assuming uniform pressure (P=constant). See figure (Q2) below. a) Find the total springs load pressing the plates to transmit 25 KW at 1575 rpm, taking μ=0.3 b) If there are 6 springs each of stiffness 13 KN/m and each of contact surface has worn away by 1.25 mm. What is the maximum power that can be transmitted if the same speed and µ? discs (driving) driving shaft (rpm) H discs (driven) direction of axial movement driven shaftarrow_forwardA steel panel is subjected to a compressive loading in order to improve the panel stiffness and to increase its buckling strength. It is swaged with the swage depth of 13 mm and swage angle of 60.07°. Its profile is as shown in Fig.Q2. Typical dimensions are shown in the figure and the thickness of the panel is 0.8 mm. The effective length of the panel is 750 mm. The relevant properties are: Modulus of elasticity Yield stress 200 GN/m? 240 MN/m? . Assuming that the buckling stress coefficient for a panel simply supported on both sides is 3.62 and that the post buckling relationship for the panel is Oy = 0.40, +0.60, where oav = average panel stress, o, = edge stress in panel and o = panel buckling stress, determine (a) the load/swage pitch at which initial buckling of the panel will ccur, (b) the instability load per swage pitch. (13 Discuss the effects upon the compressive strength of the panel of: (c) i) Varying the swage width; ii) Varying the swage depth 150 13 150 All dimensions…arrow_forwardPLEASE EXPLAINarrow_forward

- An idealized model of a thin-walled convertible car body cross-section is shown in figure Q16. The effect of doors and windows has been ignored. The car has vertical side walls of thickness t1 and length 1 m and a horizontal base of thickness t2 and length 1.9 m. It is constructed from aluminium with a shear modulus of 24 GPa. t₁ = 15 mm t2 = 15 mm a. For this open section determine the torsional stiffness? Give your answer to 3 significant figures in Pa m4 and non-scientific notation e.g. 10000 rather than 10e05. Do not include units in your answer Note that for an open section, the total area moment JT is the sum over all plates i as given by equation (1) below. Ir = = = Ei bit? Torsional stiffness = GJT t₂ 1.9 m 1m Figure Q16 - idealised model of a thin-walled convertible car bodyarrow_forwardPE Problem for Module 2.1: Solve the complex truss below by the method of substitution. See component reactions at the supports. Match the axial bar force by ticking the circle that corresponds to your answer according to your solution. * 2m 16KN 4m 16 KN a 1m 4m 4m 10 KN 10 KNarrow_forward(5) A gas engine valve spring is loaded to 35kgf when the valve is closed & 52kgf hen the valve is open. The valve lift is 8mm. The outside diameter is to be from 38mm~45mm, & the permissible stress is 413N/mm2 . Determine: (a) the wire & outside diameter; (b) the number of effective coils; (c) the free length when it is squared & ground.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY