Concept explainers

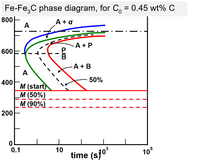

Using the isothermal transformation diagram for a 0.45 wt% C steel alloy (Figure 10.40),

determine the final microstructure (in terms of just the microconstituents present) AND

approximate percentages of the microconstituents that form in a small specimen that has been

subjected to the following time-temperature treatments. In each case assume that the

specimen begins at 845°C (1550°F), and that it has been held at this temperature long enough to

have achieved a complete and homogeneous austenitic structure.

(a) Rapidly cool to 250°C (480°F), hold for 10^3 s, then quench to room temperature.

(b) Rapidly cool to 700°C (1290°F), hold for 30 s, then quench to room temperature.

(c) Rapidly cool to 700°C (1290°F), hold at this temperature for 10^5 s, then quench to room

temperature.

(d) Rapidly cool to 400°C (750°F), hold for 500 s, then quench to room temperature.

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 2 images

- 8)arrow_forwardA cylindrical metal specimen having an original diameter of 10.63 mm and gauge length of 50.1 mm is pulled in tension until fracture occurs. The diameter at the point of fracture is 7.60 mm, and the fractured gauge length is 74.5 mm. Calculate the ductility in terms of (a) percent reduction in area (percent RA), and (b) percent elongation (percent EL). (a) i percent RA (b) i percent ELarrow_forward14) Inc a) Copper and its alloys do not fail due to cycling loading if the applied stress amplitude is below a certain level. b) Alloys with HCP crystal structure do not fail due to cycling loading if the applied stress amplitude is below a certain level. c) If there exist many slip systems such metals and alloys do not fail due to cycling loading if the applied stress amplitude is below a certain level. d) The practical rule that says there exist a fatigue limit for iron based alloys is not strictly true. 15) Indicate the incorrect expression: a) Better surface finish would help increase fatigue life. b) All kinds of inhomogenity would be detrimental in number of cycles that material can terms of the endure regardless of the stress level. c) Corrosion on a material that has excellent surface finish would not affect fatigue behavior of that part. d) Sand blasting as a source of compressive stresses would be useful under fatigue conditionsarrow_forward

- Q4/ A. Explain why ceramic materials do not response to the plastic deformation processes? Also clarify why flexural test is applied to ceramics instead of tensile test? B. Estimate whether a cylindrical aluminum oxide sample will fail or not when it subject to flexural test to achieve flexural strength of 390 MPa knowing that the sample radius is 2.5 mm, separation distance is 30 mm, and the applied load is 620 N respectively.arrow_forwardAn aluminum alloy cylindrical bar of 10 mm diameter is subjected to 5 kN tensile load which reduces the diameter of bar to 9.997 mm. If the Young's modulus of the bar is 6.95 x 104 MPa, calculate the Poisson's ratio of the alloy.arrow_forwardThe assembly shown consists of an aluminum shell (E,= 70 GPa, a, = 23.6 × 10-6rC) fully bonded to a steel core (Es = 200 GPa, as = 11.7 x 10-6rC) and the assembly is unstressed at a temperature of 20°C. Considering only axial deformations, determine the stress in the aluminum when the temperature reaches 215°C. 200 mm 20 mm Aluminum shell Steel 50 mm core The stress in the aluminum is MPa.arrow_forward

- A thin plate of a ceramic material with E = 225 GPa is loaded in tension, developing a stress of 450 MPa. Is the specimen likely to fail if the most severe flaw present is an internal crack oriented perpendicular to the load axis that has a total length 0.25 mm and a crack tip radius of curvature equal to 1 μm?arrow_forwardA ceramic part is used under a complete reverse cyclic stress with a stress amplitude (S) of 250 MPa. The yield strength and fracture toughness of materials is 550 MPa and 12.5 MPa*sqrt(m), respectively. Y is 1.4. What is the critical surface crack length?arrow_forwardA ceramic sample with a rectangular section can support a load of up to 290 N under a common strength test for ceramics. Its flexural strength is then 78.3 MPa and the distance between support points is 45 mm. What would be the dimensions of this sample if its width were twice its height?arrow_forward

- Niloarrow_forwardA cylindrical specimen of undeformed brass that has a diameter of 300 mm is elastically deformed to a tensile strain of 0.001. If the Poisson's ratio for this brass is O.35, what is the change in specimen diameter? O Decrease by 3.00 x 104 m O Decrease by 1.05 x 104 m O Increase by 1.05 x 104 m O Increase by 0.028 mmarrow_forwardA steel plate used for polymer forming is to be bent into a circular shape having an inside radius of 10 m. What maximum thickness can be used for the plate if the normal stress is not to exceed 267 MPa? Assume that the modulus of elasticity for the steel is 201 GPa.arrow_forward

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning