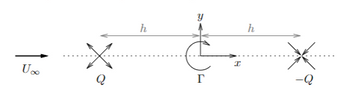

We can model potential flow over a jellybean by using a source (Q), vortex (Γ), and sink (−Q)

placed on the x axis as shown below. When combined with uniform flow (U∞), the superimposed

elementary flows will model flow over a closed shape that resembles a jellybean. For the numerical

parts below, use U∞ = 5m/s, Γ = 10m2/s, Q = 8m2/s, and h = 0.5m.

a) Write the complex potential, F (z), for this flow, in terms of z and the given parameters (not

numerical values).

b) Write the equation for the complex velocity, w(z), again in terms of the given parameters.

c) Determine the location of the stagnation points in this flow, using the given numerical values.

You should find three points, with two at the leading/trailing edge of the closed shape.

Please show all work!!

Step by stepSolved in 2 steps with 2 images

- Suppose that the length of the steel bar is measured by a number of different observers and following set of 11 measurements is recorded as set A (units mm): 398, 420, 394, 416, 404, 408, 400, 420, 396, 413, 330. Next the measurements are taken using different ruler to produce measurement set B: 409, 406, 402, 407, 405, 404, 407, 404, 407, 407, 408. It can be shown that the mean values set A and B are 409 and 406 respectively. Which of the two measurement sets A and B, and the corresponding mean value, should have most confidence in? why? Textarrow_forwardWhen does the reduction in the dimensions occur?arrow_forward8 - In general, Fair Use allows small sections of a work to qualify for copying so long as the entire work or a substantial portion of the work is not being used. TrueFalsearrow_forward

- Please hurryarrow_forwarda= 15.0 in, b= 7.0 in, c= 12.0 in, and d= 12.0 in.,(e = 3.0 in. horizontal), Draw the kinematic diagram in SolidWorks drawing sheet with size A3 iso and suitable scale. Solve the following questions and upload the SolidWorks file below. e 'a What is the degree of freedom of the mechanism? а. b. 0 С. 1 d. 4 е. 2.arrow_forwardWhen do the actual dimensions occur?arrow_forward

- 29- In a turning operation on brass with hardness = 125 HB, the cutting speed = 200 m/min, teed = 0.25 mm/rev, and depth of cut =7.5 mm. How much power will the lathe draw in performing this operation if its mechanical efficiency 90%. Use the table given below to obtain the appropriate specific energy value. Specific Energy U or Unit Power Pu Brinell Unit Horsepower HP, hp/(in'/min) Material Hardness N-m/mm in-lb/in Carbon steel 150-200 1.6 240,000 0.6 201-250 2.2 320,000 0.8 251-300 2.8 400,000 1.0 Alloy steels 200-250 2.2 320,000 0.8 251-300 2.8 400,000 1.0 301-350 3.6 520,000 1.3 351-400 4.4 640,000 1.6 Cast irons 125-175 1.1 160,000 0.4 175-250 1.6 240,000 0.6 Stainless steel 150-250 2.8 400,000 1.0 Aluminum 50-100 0.7 100,000 0.25 Aluminum alloys 100-150 0.8 120,000 0.3 Brass 100-150 2.2 320,000 0.8 Bronze 100-150 2.2 320,000 0.8 Magnesium alloys 50-100 0.4 60,000 0.15 a) 21,007 b) 38.194 10.503 d) 16.667 3332arrow_forwardInformation such as tolerances and scale can be found in the________ of an engineering drawing.arrow_forward3. GEOMETRY OF TECHNICAL DRAWING-TANGENCIES DDRAW TANGENT TO CIRCLE AT POINTP AND TANGENT FROMQ TO LOWER PORTON OF CIRCLE. 2 DRAW ARC TANGENT TO LINE AB AT B, AND THROUGH POINT C. A B DRAW ARC OF 30mm (1.20") R TANGENT TO GIVEN LINES SHOW CONSTRUCTION FOR POINTS OF TANGENCY. DRAW ARC OF 50 mm (2.00")R TANGENT TO GIVEN LINES. SHOW CONSTRUCTION FOR POINTS OF TANGENCY. DRAW ARC OF 30mm(1.20")R TANGENT TO GIVEN LINE 5 DRAW ARC OF 38 mm(1.50")R TANGENT TO GIVEN UNES. SHOW CONSTRUCTION FOR POINTS OF TANGENCY. 6. AND ARC. SHOW CONSTRUCTION FOR POINTS OF TANGENCY. 1.arrow_forward

Welding: Principles and Applications (MindTap Cou...Mechanical EngineeringISBN:9781305494695Author:Larry JeffusPublisher:Cengage Learning

Welding: Principles and Applications (MindTap Cou...Mechanical EngineeringISBN:9781305494695Author:Larry JeffusPublisher:Cengage Learning Precision Machining Technology (MindTap Course Li...Mechanical EngineeringISBN:9781285444543Author:Peter J. Hoffman, Eric S. Hopewell, Brian JanesPublisher:Cengage Learning

Precision Machining Technology (MindTap Course Li...Mechanical EngineeringISBN:9781285444543Author:Peter J. Hoffman, Eric S. Hopewell, Brian JanesPublisher:Cengage Learning Automotive Technology: A Systems Approach (MindTa...Mechanical EngineeringISBN:9781133612315Author:Jack Erjavec, Rob ThompsonPublisher:Cengage Learning

Automotive Technology: A Systems Approach (MindTa...Mechanical EngineeringISBN:9781133612315Author:Jack Erjavec, Rob ThompsonPublisher:Cengage Learning