Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

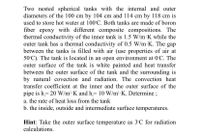

Transcribed Image Text:Two nested spherical tanks with the internal and outer

diameters of the 100 cm by 104 cm and 114 cm by 118 cm is

used to store hot water at 100 C. Both tanks are made of boron

fiber epoxy with different composite compositions. The

thermal conductivity of the inner tank is 1.5 W/m K while the

outer tank has a thermal conductivity of 0.5 W/m K. The gap

between the tanks is filled with air (use properties of air at

50°C). The tank is located in an open environment at 0'C. The

outer surface of the tank is white painted and heat transfer

between the outer surface of the tank and the surrounding is

by natural covection and radiation. The convection heat

transfer coefficient at the inner and the outer surface of the

pipe is h 20 W/m' K and h 10 W/m K. Determine;

a. the rate of heat loss from the tank

b. the inside, outside and intermediate surface temperatures.

Hint: Take the outer surface temperature as 3°C for radiation

calculations.

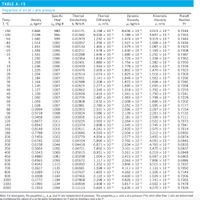

Transcribed Image Text:TABLE A-15

Properties of air at 1 atm pressure

Dynamic

Viscosity

µ, kg/m-s

Kinematic

Prandtl

Specific

Heat

Thermal

Thermal

Temp.

T, °C

Conductivity

k, W/m-K

Density

Diffusivity

Viscosity

v, m?/s

Number

P, kg/m³

Cp, J/kg-K

a, m?/s

Pr

-150

-100

8.636 x 10-6

1.189 x 10-5

2.866

983

0.01171

4.158 x 10-6

3.013 x 10-6

0.7246

8.036 x 10-6

1.252 x 10-5

1.356 x 10-5

1.465 x 10-5

1.578 x 10-5

1.696 x 10-5

2.038

966

0.01582

5.837 x 10-6

0.7263

0.01979

0.02057

-50

1.582

999

1.474 x 10-5

9.319 x 10-6

0.7440

1.527 x 10-5

1.579 x 10-5

1.630 x 10-5

1.680 x 10-5

1.729 x 10-5

1.754 x 10-5

1.778 x 10-5

1.802 x 10-5

1.825 x 10-5

1.849 x 10-5

1.872 x 10-5

-40

-30

1.514

1.451

1002

1004

1.008 x 10-5

1.087 x 10-5

0.7436

0.7425

0.7408

0.02134

0.02211

0.02288

-20

1.394

1005

1.169 x 10-5

-10

1.341

1006

1.252 x 10-5

0.7387

1.292

1006

0.02364

1.818 x 10-5

1.338 x 10-5

0.7362

1.880 x 10-5

1.944 x 10-5

2.009 x 10-5

2.074 x 10-5

2.141 x 10-5

2.208 x 10-5

1.269

1006

0.02401

1.382 x 10-5

0.7350

1.246

1.225

10

1006

0.02439

1.426 x 10-5

0.7336

15

1007

0.02476

1.470 x 10-5

0.7323

1007

1007

1007

1.516 x 10-5

1.562 x 10-5

1.608 x 10-5

1.655 x 10-5

20

1.204

0.02514

0.7309

25

1.184

0.02551

0.7296

30

1.164

0.02588

0.7282

35

1.145

1007

0.02625

2.277 x 10-5

1.895 x 10-5

0.7268

2.346 x 10-5

2.416 x 10-5

2.487 x 10-5

2.632 x 10-5

2.780 x 10-5

2.931 x 10-5

1.702 x 10-5

1.750 x 10-5

1.798 x 10-5

40

1.127

1007

0.02662

1.918 x 10-5

0.7255

1.109

0.02699

1.941 x 10-5

1.963 x 10-5

45

1007

1007

0.7241

50

1.092

0.02735

0.7228

0.02808

0.02881

2.008 x 10-5

2.052 x 10-5

2.096 x 10-5

1.896 x 10-5

1.995 x 10-5

2.097 x 10-5

2.201 x 10-5

60

1.059

1007

0.7202

1.028

0.9994

70

1007

0.7177

0.02953

0.7154

0.7132

80

1008

1008

3.086 x 10-5

3.243 x 10-5

3.565 x 10-5

2.139 x 10-5

2.181 x 10-5

2.264 x 10-5

2.345 x 10-5

90

0.9718

0.03024

100

0.9458

1009

0.03095

2.306 x 10-5

0.7111

120

0.7073

0.7041

0.8977

1011

0.03235

2.522 x 10-5

0.8542

0.8148

2.745 x 10-5

2.975 x 10-5

140

1013

0.03374

3.898 x 10-5

4.241 x 10-5

4.593 x 10-5

4.954 x 10-5

5.890 x 10-5

6.871 x 10-5

7.892 x 10-5

2.420 x 10-5

2.504 x 10-5

2.577 x 10-5

2.760 x 10-5

2.934 x 10-5

160

1016

0.03511

0.7014

180

0.7788

1019

1023

0.03646

3.212 x 10-5

0.6992

200

0.7459

0.03779

3.455 x 10-5

0.6974

0.6746

250

300

1033

0.04104

4.091 x 10-5

0.6946

4.765 x 10-5

5.475 x 10-5

0.6158

1044

0.04418

0.6935

3.101 x 10-5

3.261 x 10-5

3.415 x 10-5

3.563 x 10-5

3.846 x 10-5

350

0.5664

1056

0.04721

0.6937

6.219 x 10-5

6.997 x 10-5

7.806 x 10-5

9.515 x 10-5

8.951 x 10-5

1.004 x 10-4

1.117 x 10-4

1.352 x 10-4

1.598 x 10-4

1.855 x 10-4

2.122 x 10-4

2.398 x 10-4

3.908 x 10-4

5.664 x 10-4

0.6948

0.6965

400

0.5243

1069

0.05015

450

0.4880

1081

0.05298

500

0.4565

1093

0.05572

0.6986

600

0.4042

1115

0.06093

0.7037

4.111 x 10-5

4.362 x 10-5

700

0.3627

1135

0.06581

1.133 x 10-4

0.7092

1.326 x 10-4

1.529 x 10-4

800

0.3289

1153

0.07037

0.7149

900

0.3008

1169

0.07465

4.600 x 10-5

0.7206

1000

1500

4.826 x 10-5

5.817 x 10-5

6.630 x 10-5

0.2772

1184

0.07868

1.741 x 10-4

0.7260

0.09599

2.922 x 10-4

4.270 x 10-4

0.1990

1234

0.7478

2000

0.1553

1264

0.11113

0.7539

Note: For ideal gases, the properties C, k, µ, and Pr are independent of pressure. The properties p, v, and a at a pressure P (in atm) other than 1 atm are determined

by multiplying the values of p at the given temperature by Pand by dividing v and a by P.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A supply of 50 kg of chicken at 6degC contained in a box is to be frozen to -18degC in a freezer. Determine the amount of heat that needs to be removed. The latent heat of chicken is 247 kJ/kg and its specific heat is 3.32 kJ/kg-degC above freezing and 1.77 kJ/kg-degC below freezing. The freezing temperature of the chicken is -2.8degCarrow_forwardConsider a furnace (as a plane wall) which has a thickness of 15 cm and a surface area of 1 m?. The inside surface of the furnace wall (the hot left side of the wall) is at temperature T1. The furnace wall is made of brick with thermal conductivity of 1.198 W/m.K. The outside surface of the furnace wall (the right side of the wall) has a surface emissivity of 0.8 and is maintained at T2=101 °C and subject to air at 25 °C with convection heat transfer coefficient of 20 W/m?.K. The surroundings temperature at the outside of the furnace wall is at 25 °C. Required: Draw a clear and consistent schematic of the problem and label the operating conditions on the schematic. Perform systematic analysis, state your assumptions and justify the equation used and determine the following (circle your final answers): (i) The rate of heat transfer by convection (in W); (ii) The rate of heat radiation (in W); (iii) The surface temperature of the furnace wall T1 (in °C); (iv) The rate of conduction heat…arrow_forwardConsider a double-paned window consisting of two panes of glass, each with a thickness of 0.500 cm and an area of 0.795 m2 , separated by a layer of air with a thickness of 1.50 cm. The temperature on one side of the window is 0.00 ∘C∘C; the temperature on the other side is 21.0 ∘C∘C. In addition, note that the thermal conductivity of glass is roughly 36 times greater than that of air. Approximate the heat transfer through this window by ignoring the glass. That is, calculate the heat flow per second through 1.50 cmcm of air with a temperature difference of 21.0 ∘C∘C. (The exact result for the complete window is 25.6 J/sJ/s .)arrow_forward

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY