Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

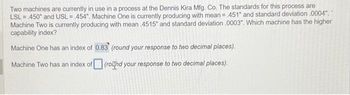

Transcribed Image Text:Two machines are currently in use in a process at the Dennis Kira Mfg. Co. The standards for this process are

LSL = 450" and USL= 454". Machine One is currently producing with mean = 451" and standard deviation .0004","

Machine Two is currently producing with mean .4515" and standard deviation .0003". Which machine has the higher

capability index?

Machine One has an index of 0.83 (round your response to two decimal places).

Machine Two has an index of (round your response to two decimal places).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 5 images

Knowledge Booster

Similar questions

- Consider a process with lower process control limit as 1.338 and upper process control limit as 1.342 . The lower specification limit is 1.335 and the upper specification limit is 1.345. Utilizing the information provided, is the process is capable of meeting design specifications?arrow_forwardS Book Hint Print eferences Problem 13-2 (Algo) A metal fabricator produces connecting rods with an outer diameter that has a 1 ± 0.02 inch specification. A machine operator takes several sample measurements over time and determines the sample mean outer diameter to be 1.004 inches with a standard deviation of 0.006 inch. Calculate the process capability index for this example. (Round your answer to 3 decimal places.) Process capability indexarrow_forward7. An ad agency tracks the complaints, by week received, about the billboards in its city: Week No. of Complaints 1 3 2 6 3 4 4 12 5 2 6 9 This exercise contains only parts a, b, and c. Part 2 a) The type of control chart that is best to monitor this process is c minus chart ______ . Part 3 b) Using z = 3, the control chart limits for this process are (assume that the historical complaints rate is unknown): UCLc = ________ complaints per week (round your response to two decimal places). The upper control limit is: ________ The lower control limit is: _________ The central limit is ___________arrow_forward

- A process generating attribute data has an estimated sigma capability = 3.3. Assuming the process mean is shifted +/- 1.5 sigma from the target value, what is the estimated dpmo? Estimated dpmo = ____.arrow_forwardBlueMoon Bottlers has a bottle-filling process with a mean value of 64 ounces and a standard deviation of 8 ounces. Suppose the upper and lower specification limits are 71 and 57 ounces, respectively. What is the process capability index of this process? (Note: You MUST show every single step and detailed derivation for full credit)arrow_forwardTwelve samples, each containing five parts, were taken from a process that produces steel rods at Emmanual Kodzi's factory. The length of each rod in the samples was determined. The results were tabulated and sample means and ranges were computed. The results were: Sample Sample Mean (in.) Range (in.) Sample Sample Mean (in.) Range (in.) 1 11.404 0.044 7 11.403 0.021 2 11.400 0.051 8 11.407 0.058 3 11.389 0.042 9 11.397 0.039 4 11.406 0.037 10 11.403 0.038 5 11.395 0.048 11 11.401 0.054 6 11.397 0.053 12 11.406 0.061 Part 2 For the given data, the x = enter your response here inches (round your response to four decimal places). The control limits for the 3-sigma R-chart are (round all intermediate calculations to three decimal places before…arrow_forward

- What is the meaning of x ̅ ~ N (50, 2)? 1. The Sampling distribution is distributed normally with a mean of 50 and a standard deviation of 2 2. Sampling distribution of x is distributed normally with a mean of 2 and a standard deviation of 50 3. x is normally distributed with a mean of 50 and a standard deviation of 2 4. x-bar is normally distributed with a mean of 2 and a standard deviation of 50arrow_forwardThe director of research and development is testing a new drug. She wants to know if there is evidence at the 0.05 level that the drug stays in the system for more than 399 minutes. For a sample of 81 patients, the mean time the drug stayed in the system was 401 minutes. Assume the standard deviation is known to be 21. Step 1 of 5: Enter the hypotheses: Step 2 of 5: Enter the value of the z test statistic. Round your answer to two decimal places. Step 3 of 5: Specify if the test is one-tailed or two-tailed. Step 4 of 5: Enter the decision rule. Step 5 of 5: Enter the conclusion.arrow_forward50 motor generators are inspected per day from a stable process. The best estimate of the fraction of nonconforming is 0.076. Determine the centeral line and control limits. On a particular day, 5 nonconforming generators were discovered. Is this process in or out of control? For the information given in the problem, construct a np-chartarrow_forward

- Design specifications require that a key dimension on a product measure 106 ± 12 units. A process being considered for producing this product has a standard deviation of five units. What can you say (quantitatively) regarding the process capability? Assume that the process is centered with respect to specifications. answer 0.8000 Suppose the process average shifts to 98. Calculate the new process capability. Note: Round your answer to 4 decimal places. ? What is the probability of defective output after the process shift? ?arrow_forwardA metal fabricator produces connecting rods with an outer diameter that has a 1± 0.02 inch specification. A machine operator takes several sample measurements over time and determines the sample mean outer diameter to be 1.005 inches with a standard deviation of 0.003 inch. Calculate the process capability index for this example. Note: Round your answer to 3 decimal places. Process capability indexarrow_forwardC: Determine the UCL and LCL for a X−�− chart. Note: Round your answers to 3 decimal places. D: Determine the UCL and LCL for R-chart. Note: Leave no cells blank - be certain to enter "0" wherever required. Round your answers to 3 decimal places. E: What comments can you make about the process? multiple choice Process is in statistical control Process is out of statistical controlarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.