Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Present your complete-detail solution including the free- body diagrams.

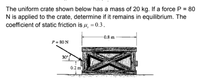

Transcribed Image Text:The uniform crate shown below has a mass of 20 kg. If a force P = 80

N is applied to the crate, determine if it remains in equilibrium. The

coefficient of static friction is µ,

= 0.3.

0.8 m

P = 80 N

30°

0.2 m

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 15.27 For the solid model of a fixture shown in Figure P15-27, the inside surface of the hole is subjected to a temperature increase of 80° C. The right end surfaces are fixed. Determine the von Mises stresses throughout the fixture due to this temperature increase. What is the largest von Mises stress? Is it a concern against yielding of the material? Assume the material is AISI 1020 cold-rolled steel. Figure P15-27. 40 mm 75 mm 30 dia. Fixed 20 rad. 30 mm Fixed 50 mm- 15 mm (All dimensions in mm units) Harrow_forwardPlease help.arrow_forwardPlease help me answer this problem ASAP badly needed. Thank youarrow_forward

- Describe the steelmaking process to obtain a cold thin coil, in SAE 1008 steel, MSG 20 (thickness 0.91 mm) plate with a width of 600 mm starting from a hot-rolled plate. MSG 8 (thickness 4.25 mm) with a width of 1200 mm Requirements: LE min = 300 MPa, LR between 400 and 500 MPa and A min = 20%. The sheet must have a good surface finish and dimensional control. Ensure high Tenacity. Cite and justify the necessary process. Cite the hardening mechanisms usedarrow_forwardProblem#3: You need to design a metallic glass for use in industry. The glass transition temperature of the metallic glass is 250°C. While in use, the sample will be subjected to a permanent tensile stress for tuse=6 years and at a temperature of Tuse=230°C. You need to do the necessary creep experiment in the lab to predict the performance of this material by applying the same stress at different temperature and different time. The creep test will be carried out for tiab=6 hours. At what temperature, Tlab, can this test be performed in the lab under the same tensile stress? [Hint: Use WLF and VFT equations for two cases: 1) Tref=Tg =250 °C and 2) Tr=260 °C.]arrow_forwardProvide 3-dimensional Equation for Hooks Law for strain and for Shear?arrow_forward

- !arrow_forwardGive an example of Support Reaction?arrow_forwardDetermine the single uniformly distributed load in the x direction that would produce the same deformation in the y direction as the original loading for a given rectangular block with the following data: 4 inches long in the x direction, 2.5 inches long in the y direction, and 3.5 inches long in the z direction. The block is subjected to a triaxial loading of three uniformly distributed forces as follows: 52 kips tension in the x direction, 68 kips compression in the y direction, and 49 kips tension in the z direction. Given v = 0.28 and E = 30 x 10° psi, O a. 265.23 kips O b. 255.80 kips Oc 220.25 kips O d. 246.56 kipsarrow_forward

- Q1: How do your results for μs and μk compare to literature values for dry metal on plastic? Cite what you compared to. Do they agree with the literature within error? If not, discuss any systematics that could have contributed to the discrepancy. Q2: Is the force of static friction constant as the incline rises? Explain your answer. My Us value is 0.4452, and Uk value is 0.33arrow_forwardIf the plate thickness in the previous problem were 1 cm, would the thickness be sufficient for a JIC test? Assume these material properties: E = 205 GPa, v = 0.25.arrow_forwardDo the torsion tests, give accurate results?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY