Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

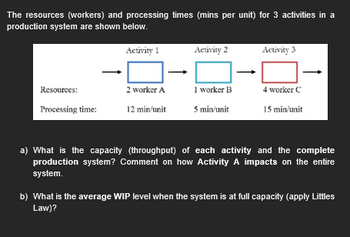

Transcribed Image Text:The resources (workers) and processing times (mins per unit) for 3 activities in a

production system are shown below.

Resources:

Processing time:

Activity 1

1-

2 worker A

12 min/unit

Activity 2

1 worker B

5 min/unit

Activity 3

4 worker C

15 min/unit

a) What is the capacity (throughput) of each activity and the complete

production system? Comment on how Activity A impacts on the entire

system.

b) What is the average WIP level when the system is at full capacity (apply Littles

Law)?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- A local toy manufacturer is using a production line that runs 8 hours per day and produces a toy that requires a total of 7 tasks to be performed. The daily demand is 100 toys. Times of the tasks are 2.73, 2.01, 2.13, 2.0, 2.61, 2.71, and 2.95 minutes for A, B, C, D, E, F, and G, respectively. However, due to the nature of the product there are precedence rules that must be observed. Such that Task A does not need any predecessors; task B requires task A to be completed. To start task C and task D, each require task B to be completed. Task C must be completed prior to stating task E. Task F needs both task D and task E to be completed. Finally, task G can start only once task Fis completed. Given we apply the most remaining tasks rule for balancing the assembly line, with ties broken according to longest task time first, What will the estimated idle time in minutes for THIRD workstation? O a. 1.00 O b. None is the correct answer 0.06 O d. 1.85 e. 0.09arrow_forward9-6. What cycle time would match capacity and demand if demand is 120 units a day, there are two shifts of 480 minutes each, and workers are given three half-hour breaks during each shift, one of which is for lunch or dinner?arrow_forwardWhich operation is the bottleneck of this process? a. Stocking b. Pricing c. Spotting d. Shipping e. Impossible to determinearrow_forward

- A local toy manufacturer is using a production line that runs 8 hours per day and produces a toy that requires a total of 7 tasks to be performed. The daily demand is 100 toys. Times of the tasks are 2.73, 2.01, 2.13, 2.0, 2.61, 2.71, and 2.95 minutes for A, B, C, D, E, F, and G, respectively. However, due to the nature of the product there are precedence rules that must be observed. Such that Task A does not need any predecessors; task B requires task A to be completed. To start task C and task D, each require task B to be completed. Task C must be completed prior to stating task E. Task F needs both task D and task E to be completed. Finally, task G can start only once task F is completed. Given we apply the most remaining tasks rule for balancing the assembly line, with ties broken according to longest task time first, the tasks that will be assigned to the THIRD workstation are O a. E only O b. D and F OC. B, C, and D d. None is the correct answer O e. D onlyarrow_forwardWhich the following is a measure of the reserve capacity, a process has to handle among in unexpected increases in demand a. Capacity cushion b. Capacity bottleneck c. Capacity limit d. Capacity Planningarrow_forwardCanine Kennels Company (CKC) manufactures two different types of dog chew toys (A and B, sold in 1,000-count boxes) that are manufactured and assembled on three different workstations (W, X, and Y) using a small-batch process (see the figure below). Batch setup times are negligible. The flowchart denotes the path each product follows through the manufacturing process, and each product's price, demand per week, and processing times per unit are indicated as well. Purchased parts and raw materials consumed during production are represented by inverted triangles. CKC can make and sell up to the limit of its demand per week; no penalties are incurred for not being able to meet all the demand. Each workstation is staffed by a worker who is dedicated to working on that workstation alone and is paid $6 per hour. Total labor costs per week are fixed. Variable overhead costs are $3,500/week. The plant operates one 8-hour shift per day or 40 hours/week. Which of the three workstations, W, X, or…arrow_forward

- A process is accomplished in 4 sequential steps- S1, S2, S3 and S4. The lead times (in minutes) and the number of resources for every step are indicated in the table below. Sub - Process Time (min) No of resources S1 12 1 S2 8 1 S3 16 1 S4 10 1 Assuming infinite demand, what is the process flow rate? {keep the time dimension as minutes for this, and answer in decimals). Hi all, I do not know how to answer this questions. Please review and advise. Thank youarrow_forwardPvnarrow_forwardOperation 1 Work Center A 2B 3 4 C D SE 5 Hourly Unit 70 80 100 50 60 60 Output Rate Product X is manufactured by starting with raw material and then processing it sequentially through 5 operations using work centers A to E resepectively (see diagram). The hourly rates for each machine are given in the table. What is the maximum output per hour for product X?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.