Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

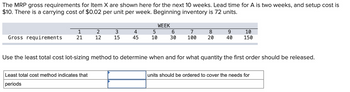

Transcribed Image Text:The MRP gross requirements for Item X are shown here for the next 10 weeks. Lead time for A is two weeks, and setup cost is

$10. There is a carrying cost of $0.02 per unit per week. Beginning inventory is 72 units.

WEEK

1

2

3

4

5

6

7

8

9

10

Gross requirements

21

12

15

45

10

30

100

20

40

150

Use the least total cost lot-sizing method to determine when and for what quantity the first order should be released.

Least total cost method indicates that

periods

units should be ordered to cover the needs for

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- Flora's Fabulous Fontains top product is its Model A. Flora is preparing for her busy season and is building 1,800 Model A fountains. Calculate the gross requirements for each component assuming that there is no beginning inventory. Use the following information: Component Immediate Parent Usage per Parent A none - B A 2 C A 1 D A 3 E A 2 F B 4 G B 2 H D 4 I D 2 J E 1 K E 6 L E 2 M F 3 N F 5 O H 2 P K 1 Q K 2 Put the answers down into the table: (If answer is zero, please enter 0, do not leave any fields blank) Component Gross Requirement A enter the gross requirement B enter the gross requirement C enter the gross requirement D enter the gross requirement E enter the gross requirement F enter the gross requirement G enter the gross requirement H enter the gross requirement I enter the gross requirement J enter the gross requirement…arrow_forwardJA manufacturing company produces finished products as well as re- placement parts. One particular product has the following bill of materials: 2. (4) D (30) (25) (20) The manufacturer independent demand requirements for both the parent item as well as the subassemblies for the next 8 weeks: Independent Period Demand 2 4 6. Assembly A Assembly B 25 25 25 15 15 15 70 100 70 100 25 25 25 25 25 Assembly C 15 15 15 15 15 Assemblies D and E are purchased from a supplier so they are not manufac- tured by the company, and therefore have no independent demand. CRarrow_forwardComplete the MPS record below for a single item. (Enter your responses as integers. A response of "0" is equivalent to being not applicable.) Order Policy: 100 units Lead Time: 1 week February Item: A Quantity on Hand: 80 Forecast Customer orders (booked) Projected on-hand inventory MPS quantity 1 60 35 20 0 January 2 70 15 3 18 8 60 90 BID 4 40 0 LE Week 5 45 30 6 45 70 7 55 0 8 50 0arrow_forward

- 2.7 Which of the following help explain how the Reorder Point (ROP) works in conjunction with the Economic Order Quantity (Q), the number of orders (N) and the time between orders (T)? a) The Economic Order Quantity (Q) and the Annual Demand (D) are used to determine the number of Order (N) b) The number of orders (N) and the number of days that a firm works (W) are used to determine the time span between orders (T) c) Orders are placed every T days unless the inventory on hand fall to or below the Reorder Point d) Only a and b e) f) Only b and c All of a, b and c 2.8 The objective of Inventory Management is to balance inventory investment (cost) and customer service. a) TRUE b) False 2.9 The Economic Order Quantity (EOQ), the number of orders, the Reorder Point (ROP), the time between orders are important analytics in Inventory Management. a) TRUE b) FALSE 2.10 The number of working days for a firm is an important input in calculating the components of the Economic Order Quantity…arrow_forwardComplete the master productin schedule based on thefollowing information:Week 1 2 3 4 5 6 7 8 9Forecast 320 100 30 110 40 240 290 60 410Customer Orders 60 50 80 20 60 60 0 0 0Projected On-Hand Inventory 600MPS ReleasedMPS DueAvailable-to-promise (ATP) Scheduled production whenever projected on-had inventory drops below 30MPS lot size: 300Production lead time or lead time for MPS releases 1arrow_forwardAssume you are the manager of a shop that assembles power tools. You have just received an order for 55 chain saws, which are to be shipped at the start of week 8. Pertinent information on the saws follows: Item Lead Time (weeks) On Hand Saw A B C D E F 2 1 2 2 1 1 2 Gross requirements Scheduled receipts Projected on hand Net requirements Planned order receipt Planned order release Ĉ E(3) & E(2) LT = 1 week Lot size: Lot-for-Lot 15 10 5 65 20 10 30 Skip Extension Tip: Double click to open in new tab Show Transcribed Text Develop the material requirements plan for component E using lot-for-lot ordering for all items. (Leave no cells blank - be certain to enter "0" wherever required.) Components A(2), B(1), C(4) E(3), D(1) D (2), F(3) E(2), D (2) Beg. Inv. 1 2 3 190 5 210 6arrow_forward

- Flora is preparing for her busy season and is building 2500 Model A fountains. Calculate the gross requirements for each component assuming that there is no beginning inventory. Component Immediate Parent Usage per Parent Lead Time (weeks) Beginning Inventory A none — 1 0 B A 2 2 250 C A 1 6 500 D A 3 3 750 E A 2 2 750 F B 4 2 3000 G B 2 4 1000 H D 3 2 5000 I D 2 4 5000 J E 1 8 1000 K E 5 1 5000 L E 2 4 2500 M F 3 3 250 N F 6 3 2560 O H 2 4 0 P K 1 2 500 Q K 2 3 1000arrow_forwardExplain how is ordering in small lot sizes essential for just in time implementation and what benefi are epected to be achieved ?arrow_forwardA company produces skateboards. Each skateboard (A) consists of one unit of board (B), and two units of sub-assembly of roller-set (C). Roller-sets comprise of 2 components: 2 rollers (D) and one axle (E). The MPS is as follows: Week 1 2 3 4 5 6 7 8 9 10 A D 40 50 60 80 What are the planned order releases for item A? A has an on-hand inventory of 10, safety stock of 0. The lead time is 1 week and the ordering policy is Lot-for-Lot (L4L).arrow_forward

- Complete the master production schedule (enter your responses as whole numbers). On-hand inventory at end of week 1: 190 Week Forecasted demand Booked orders Projected ending inventory Master production schedule Available to promise 2 280 125 680 770 3 400 170 280 4 290 265 640 650 5 250 150 390 6 260 265 965 840 7 250 240 715 8 290 125 1295 870 555 9 310 190 985arrow_forwardK Develop a lot-for-lot solution and calculate total relevant costs for the gross requirements in the following table*. Period 1 Gross requirements 30 Develop a lot-for-lot solution (enter your responses as whole numbers). Period Gross requirements On-hand at beginning of period On-hand at end of period Order receipt Order release 2 40 3 40 1 30 U 4 2 *Holding cost = $2.50/unit/week; setup cost = $150; lead time = 1 week; beginning inventory = 40. 5 6 7 30 70 20 3 40 8 4 9 10 10 80 5 6 7 30 70 20 8 11 9 10 D 12 50 10 11 12 80 50arrow_forwardOne unit of A is composed of two units of B and three units of C. Each B is composed of one unit of F. C is made of one unit of D, one unit of E, and two units of F. Items A, B, C, and D have 28, 40, 36, and 25 units of on-hand inventory. Items A, B, and C use lot-for-lot (L4L) as their lot-sizing technique, while D, E, and F require multiples of 62, 110, and 90, respectively, to be purchased. B has scheduled receipts of 15 units in Period 1. No other scheduled receipts exist. Lead times are one period for Items A, B, and D, and two periods for Items C, E, and F. Gross requirements for A are 15 units in Period 1, 12 units in Period 2, 50 units in Period 6, and 50 units in Period 8. Find the planned order releases for all items. (Leave no cells blank - be certain to enter "O" wherever required.) Period 3 4 6 7 8 Gross requirements Item A Scheduled receipts OH = 28 Projected available balance Net requirements Planned order receipts Planned order releases LT = 1 SS = 0 Q = L4L Gross…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.