Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

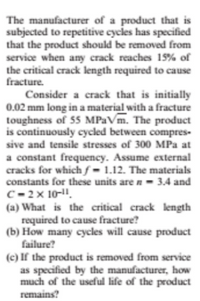

Transcribed Image Text:The manufacturer of a product that is

subjected to repetitive cycles has specified

that the product should be removed from

service when any crack reaches 15% of

the critical crack length required to cause

fracture.

Consider a crack that is initially

0.02 mm long in a material with a fracture

toughness of 55 MPaVm. The product

is continuously cycled between compres-

sive and tensile stresses of 300 MPa at

a constant frequency. Assume external

cracks for whichƒ= 1.12. The materials

constants for these units are n- 3.4 and

C- 2x 10-1.

(a) What is the critical crack length

required to cause fracture?

(b) How many cycles will cause product

failure?

(c) If the product is removed from service

as specified by the manufacturer, how

much of the useful life of the product

remains?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- Prove each of the following equations separately 30 0x - 270 ([1-sin() sin(³9)] y Exy| Oxx 30 cos 1+ sin sin 270 30 K cos() sin() cos(32) K₁ x 2.70 Stresses near the tip of a crack in an elastic material. Crack FIGURE COSarrow_forward(c) A piece of material is subjected to tensile stress of 70 N/mm² in one direction and a compressive stress of 50 N/mm² in a direction at right angles to the previous one. Find fully the stresses on a plane the normal of which makes an angle of 40 degree with the 70 N/mm² stress.arrow_forward4. The following creep data were obtained for a metal alloy tested under a constant load and at a constant temperature (the initial length of the unloaded sample was 2.0 inches): Sample Length (in) Time (hr) 2.004 2.01 100 2.02 200 2.03 400 2.045 1000 2.075 2000 2.135 4000 2.193 6000 2.23 7000 2.30 8000 (fracture) a.) Plot the strain versus time (in hours) curve for this material. b.) Determine the steady-state creep rate.arrow_forward

- A very large, steel plate of yield stress 200 MPa has a crack at the centre of length 18 mm, orientated along the x-axis. If the plate is subjected to far field tensile loading of magnitude 179 MPa and is assumed to be in a state of plane strain, determine the extent of the plastic region at the crack tip, along the x-axis. You may assume Poisson's ratio is (1/3). Express your answer as an integer value of mm.arrow_forwardA brass specimen of the circular cross-section is fractured at 151 kN force and the final length of the specimen at fracture is 48 mm. The fracture strength of the specimen is found to be 72 kN/mm?. The percentage of elongation of the specimen is 44 %. Determine the following (i) Diameter of the specimen, ii) Initial length of the specimen, iii) Stress under an elastic load of 15 kN, iv) Young's Modulus if the elongation is 1.5 mm at 15 kN (v) Final diameter if the percentage of reduction in area is 21 %. ( Initial Cross-sectional Area (in mm?) The Diameter of the Specimen (in mm) Initial Length of the Specimen (in mm) Stress under the elastic load (in N/mm?) Young's Modulus of the Specimen (in N/mm2) Final Area of the Specimen at Fracture (in mm) Final Diameter of the Specimen after Fracture (in mm)arrow_forwardThe principal stresses at a point are 20 (tensile) and o (compressive), and the stress at elastic limit for the material in simple tension is 210 N/ mm². According to maximum shear strain theory, the value of oat failure is (a) 70 N/mm² (c) 140 N/mm² (b) 105 N/mm² (d) 210 N/mm²arrow_forward

- compare the effect of presence of a notch on ductile and brittle materials in terms of fracture behaviourarrow_forwardState the difference between cleavage and fracture of minerals, using quartz and mica as examples.arrow_forward(b) An aluminium plate (100 mm width x 300 mm height x 4 mm thick) with a centre-crack is subjected to a mode-l service load of 40 kN. Assume that the fracture toughness of the material is 24 MPa Vm and Y-1.0. (ii) What is the safety factor on crack length? Assume that the yield strength of aluminium is 425 MPa.arrow_forward

- Is the fracture in the picture below brittle or ductile? Where is the location of the initiation of the fracture and why?arrow_forward2. The Goodman diagram relates oa and om for fatigue failure after a specific number of cycles Nf, where da is the cyclic stress amplitude, and om the mean stress. For a steel specimen it is found that oa oa (0). [1- (om/OTS)] where Ors is the metal's tensile stress (375MPa), and oa (0)~0.450TS is the 107 cycle fatigue limit at zero mean stress. Assuming the specimen is cycled repeatedly between 0 stress and a peak stress, what is the maximum peak stress if failure in < 107 cycles is to be avoided? Ans: 233 MPaarrow_forwardDon't copy and complete solution pleasearrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning