Materials Science And Engineering Properties

1st Edition

ISBN: 9781111988609

Author: Charles Gilmore

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

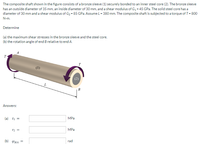

Transcribed Image Text:The composite shaft shown in the figure consists of a bronze sleeve (1) securely bonded to an inner steel core (2). The bronze sleeve

has an outside diameter of 35 mm, an inside diameter of 30 mm, and a shear modulus of G2 - 45 GPa. The solid steel core has a

diameter of 30 mm and a shear modulus of G2 - 85 GPa. Assume L - 380 mm. The composite shaft is subjected to a torque of T- 800

N-m.

Determine

(a) the maximum shear stresses in the bronze sleeve and the steel core.

(b) the rotation angle of end B relative to end A.

(1)

L

B

Answers:

MPa

(a) TI =

MPa

rad

(b) PBIA =

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- The data in Table 1.5.3 were obtained from a tensile test of a metal specimen with a rectangular cross section of 0.2011in.2 in area and a gage length (the length over which the elongation is measured) of 2.000 inches. The specimen was not loaded to failure. a. Generate a table of stress and strain values. b. Plot these values and draw a best-fit line to obtain a stress-strain curve. c. Determine the modulus of elasticity from the slope of the linear portion of the curve. d. Estimate the value of the proportional limit. e. Use the 0.2 offset method to determine the yield stress.arrow_forwardThe composite shaft shown in the figure consists of a bronzesleeve (1) securely bonded to an inner steel core (2). The bronze sleeve has an outside diameter of 25 mm, an inside diameter of 20 mm, and a shear modulus of G1 = 45 GPa. The solid steel core has a diameter of 20 mm and a shear modulus of G2 - 83 GPa. Assume L - 470 mm. The composite shaft is subjected to a torque of T-970 N-m. Determine a) the maximum shear stresses in the bronze sleeve and the steel core. b) the rotation angle of end B relative to end A. Answers: (a) TI = MPa T2 = MPa (b) PRIA = radarrow_forwardPROBLEM 1) An aluminum bar carries the axial loads at the positions shown. If E=70GPA, compute the total deformation of the bar. Assume that the bar is suitably braced to prevent buckling. 0.4m D 10KN 0.8m 0.4m B 5KN 0.6m AL 20KN What is the deformation &pE in mm? A=800 mm² A=1,200 mm²arrow_forward

- An aluminum tube is fastened between a steel rod and a bronze rod as shown. Axial loads are applied at the positions indicated. For Bronze: Allowable stress = 120 MPa, EB = 83,000 MPa For Aluminum: Allowable stress = 120 Mpa, EA = 70,000 MPa For Steel: Allowable stress = 120 MPa, Es = 200,000 MPa Assume that the assembly is suitably braced to prevent buckling. Maximum overall deformation should not exceed 2mm. a) Give the value of the force acting on the bronze so as not to exceed allowable stresses and deformation. b) Give the value of the force acting on the aluminum so as not to exceed its allowable stresses and deformation. c) Give the value of the force acting on the steel so as not to exceed its allowable stresses and deformation.arrow_forwardAn AISI 1040 hot-rolled steel [E = 207 GPa; α = 11.3×10–6/°C] bar is held between two rigid supports. The bar is stress free at a temperature of 30°C. The bar is then heated uniformly. If the yield strength of the steel is 429 MPa, determine the temperature at which yield first occurs.arrow_forwardProblem 1.5-2 A bar of length 2.0 m is made of a structural stoel having the stres-strain dingram shown in the figure. The yield stresa of the steel is 250 MPa and the slope of the initial lincar part of the stress-strain curve (modulus of elasticity) is 200 GP. The bar is loaded axially until it eklongates 6.5 mm, and then the load is removod. How does the final length of the bar compare with its orig- inal length? Hint: Ue the concepts illustrated in Fig. 1-36h) MP 300 200 100 0.002 0.004 0.006arrow_forward

- The composite shaft, consisting of aluminum, copper, and steel sections, is subjected to the loading shown. Determine the displacement of end A with respect to end D. The cross-sectional area and modulus of elasticity for each section are shown in the figure. Neglect the size of the collars at B and C 16 kN 8 KN 9 KN 450 mm- 16 KN C 300 mm- Section AB is Aluminum with Young's modulus of 70 GPa and an area of 63 mm². Section BC is Copper with Young's modulus of 126 GPa and an area of 87 mm². Section CD is Steel with Young's modulus of 200 GPa and an area of 39 mm. The displacement of end A with respect to end Dis Note: Please enter your answer with three significant digits after the decimal point. .mm 8 KN 400 mm- 7 KNarrow_forwardProblem 2: A bronze bar is fastened between a steel bar and an aluminum bar as shown. Axial loads are applied at the positions indicated. Find the largest value of P that will not exceed an overall deformation of 3.0 mm, or the following stresses: 140 MPa in the steel, 120 MPa in the bronze, and 80 MPa in the aluminum. Assume that the assembly is suitably braced to prevent buckling. Use Est = 200 GPa, Eal = 70 GPa, and Ebr = 83 GPa. Steel Bronze 480 mm² 650 mm² 3P 1.0 m 4P 2.0 m Aluminum 320 mm² 1.5 m 2Parrow_forwardQuestion isarrow_forward

- #2 will upvote to anyone who will answerarrow_forward1. See figure below and solve for the maximum value of torque the composite shaft can accommodate given a maximum shear stress of 8ksi in bronze and 12 ksi for the steel. Assume bronze has G = 6 × 103 ksi, and for steel, G = 12 × 103 ksi. %3| L C2" 3" Hollow Bronze Steel Core D = 3 in, d = 2 in D = 2 inarrow_forward1.(e) The state of plane stress shown occurs at a critical point of a steel machine component. As a result of several tensile tests. It has been found that the tensile yield strength is o, = 250 MPa for the grade of steel used. Determine the factor of safety with respect to yield using (a) the maximum shearing stress criterion, and (b) the maximum distortion energy criterion. ↑Y 40 MPa 80 MPa 25 MPaarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:9781111988609

Author:Charles Gilmore

Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...

Civil Engineering

ISBN:9781337094740

Author:Segui, William T.

Publisher:Cengage Learning