Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

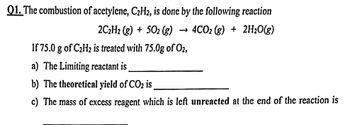

Transcribed Image Text:Q1. The combustion of acetylene, C₂H2, is done by the following reaction

2C₂H2 (g) +502 (g) 4CO2 (g) + 2H₂O(g)

If 75.0 g of C₂H₂ is treated with 75.0g of O2,

a) The Limiting reactant is

b) The theoretical yield of CO₂ is

c) The mass of excess reagent which is left unreacted at the end of the reaction is

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps

Knowledge Booster

Similar questions

- As reported in US Patent 4203923, cyclohexanone is an important chemical raw material in the production of nylon intermediates. The separation and purification section for cyclohexanone production usually done through a series of distillation units. Liquid mixture of cyclohexanone (1) and phenol (2) was reported to exist in equilibrium with its vapor at 144 °C (417.15K). The system conforms closely to Modified Raoult’s Law. The mixture forms azeotrope at composition of 0.695. (Refer Table) (a) Provide a sketch that clearly shows that the system exhibits azeotrope(α12)x1=0 = P1sat eA / P2sat and (α12)x1=1 = P1sat / P2sat eA (b) State Paz and sketch a P-xy diagram of the systemarrow_forwardThe decomposition of N,0, can be described by the equation 2 N,0,(soln) → 4NO, (soln) + O,(g) Consider the data in the table for the reaction at 45 °C in carbon tetrachloride solution. 1 (s) [N,O3] (M) 2.576 215 2.250 456 1.934 755 1.602 Given the data, calculate the average rate of reaction for each successive time interval. What is the average rate of reaction for the time interval from 0 s to 215 s? average rate of reaction: M/s What is the average rate of reaction for the time interval from 215 s to 456 s? average rate of reaction: M/s What is the average rate of reaction for the time interval from 456 s to 755 s? average rate of reaction: M/sarrow_forwardNaOH (Caustic soda) may be produced in a process from the following reactions: CaCO3 = CaO + CO2 CaO+H2O = Ca(OH)2 2NaCl + CaCO3 = Na2CO3 + CaCl2 Na2CO3+ Ca(OH)2 = 2 NaOH + CaCO3 1. Write the overall reaction for NaOH production using salt (NaCl), limestone (CaCO3) and water (H2O) as raw materials 2. What are the required feed rates of salt (NaCl), limestone (CaCO3) and water (H2O) required to produce 1000 lbm/day of NaOH as a 10% wt solution.arrow_forward

- (a) Consider the following chemical reaction: 3FE203(s) + CO(g) → 2Fe304(s) + CO2(g) AH° = ? Use the following thermochemical data to determine the enthalpy change of this reaction. (6) 2FE2O3 (s) AH° = -1652 kJ 4Fe(s) + 302(g) C(s,graphite) + ½O2(g) → CO(g) 3Fe(s) + 202 (g) → CO2(g) AH° = -110.5 kJ Fe304(s) C(s,graphite) + O2(g) AH° = -1117 kJ AH° = +395.5 kJ (b) What is the standard enthalpy of formation of carbon dioxide? (2)arrow_forwardAlumina from bauxite separation stage calculations A crucial step in the production of aluminum from bauxite ore is the separation of alumina from the remaining mineral impurities in the ore. In the Bayer process this is accomplished by treating bauxite with aqueous NaOH to produce NaAIO2 (alumina). NaOH(aq) + Al(OH)3(s) → NaAIO2(aq) + 2H2O(1) Since NaAIO2 is water soluble while the residual mineral constituents of bauxite are not, a separation can be achieved by allowing the minerals to settle out and decanting the aqueous solution of NAAIO2 and unreacted NaOH. In order to further recover any NAAIO2 entrained in the settled mineral solids, this "mud" is repeatedly washed with water and allowed to settle, and the wash water is decanted. The figure below shows one stage of this washing-settling process. Wash water Slurry - Open to air Mixer/Wash tank Setling tank Decanted solution System boundary Washed mud In this stage, a feed slurry consisting of 10 wt% solids, 11 wt% NaOH, 16 wt%…arrow_forwardBasic Principles of Chemical Engineering Question Please solve step by steparrow_forward

- A batch process is operated with the following sequence. The feed to the batch process consists of a solution of 500 L of ethanol with 120 mole of A and 120 mole of B. If the temperature of the solution is sufficient, A and B will react to form P (the desired product): A (eth) + B (eth) → P (s) DHreact = − 250 kJ/mol (1) product P is sparingly soluble in ethanol, which helps facilitate its removal from the reaction solution. It can be assumed that the reaction rate is first-order in both the concentration of A (cA ) and B (cB ), and so second-order overall: -r A = k c A cB (2) The batch process consists of the following FOUR steps: Initially, the tank is empty. 1. Fill tank with solution (ethanol/A/B). 50°C (1 hour) Increase temperature of the feed from 20°C to 2. Reaction takes place isothermally at 50°C (4 hours, to give conversion of 50%) 3. Filtration of reaction solution to give product P (2 hours) 4. Drying with hot nitrogen gas followed by the removal of powder product (3…arrow_forwardNitromethane, CH3NO2 , can be used as a fuel. When the liquid is burned, the (unbalanced) reaction is mainlyCH3NO2(l) + O2(g) → CO2(g) + N2(g) + H2O(g)a. The standard enthalpy change of reaction (ΔH°van ) for the balanced reaction (with lowest whole-number coefficients) is −1288.5 kJ. Calculate ΔHf0 for nitromethane.b. A 15.0-L flask containing a sample of nitromethane is filled with O2 and the flask is heated to 100.°C. At this temperature, and after the reaction is complete, the total pressure of all the gases inside the flask is 950. torr. If the mole fraction of nitrogen (χnitrogen) is 0.134 after the reaction is complete, what mass of nitrogen was produced?arrow_forwardAcetylene is produced from methane in the following reaction 2CH. (g) → C₂H₂(g) + 3H₂(g) An undesired side reaction is the decomposition of acetylene C₂H₂ (g) →2C₂(c) + H₂(g) Methane at 1000° C is fed to the reactor at a rate of 10 mol/s. The reactor operates isothermally at 1000° C. a. The fractional conversion of methane is 0.60 and the molar ratio of acetylene produced to methane consumed is 0.417. Calculate the rate of heat transfer (in kW) from/to the reactor. (Q= + 1100 kW) b. Calculate the rate of heat transfer (in kW) from/to the reactor if no side reaction occurs and the reaction goes to completion. 1819I ||arrow_forward

- Label the acid, base, conjugate acid and conjugate base in the following reactions: a.) NH3 (aq) + H2O (l) ⇌ NH3+ (aq) + OH– (aq) b.) H2S (g) + HF (aq) ⇌ F– (g) + H3S+ (g) c.) HCl (g) + CH3OH (g) ⇌ CH3OH2+ (g) + Cl– (g)arrow_forward11.7 mole dichloromethane (CH2Cl2) enter a reactor with 21.6 mole hydrogen (H2) and 37.5 mole oxygen (O2). The following reaction takes place: CH2Cl2 + H2 + 3/2 O2 → COCl2 + 2 H2O 6.4 mole of H2O are produced. Calculate the extent of the reaction.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The