Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

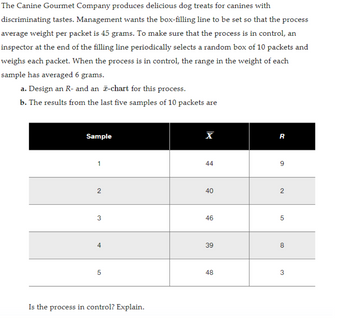

Transcribed Image Text:The Canine Gourmet Company produces delicious dog treats for canines with

discriminating tastes. Management wants the box-filling line to be set so that the process

average weight per packet is 45 grams. To make sure that the process is in control, an

inspector at the end of the filling line periodically selects a random box of 10 packets and

weighs each packet. When the process is in control, the range in the weight of each

sample has averaged 6 grams.

a. Design an R- and an e-chart for this process.

b. The results from the last five samples of 10 packets are

Sample

1

2

3

4

5

Is the process in control? Explain.

X

44

40

46

39

48

R

9

2

5

8

3

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 4 images

Knowledge Booster

Similar questions

- If a point on a control chart falls outside one of the control limits, this suggests that the process output is non-random and should be investigated. O a. TRUE O b. FALSE 10 19 NEXT PAGE 28 IOUS PAGE Finish at 82°F Mostly erarrow_forwardNorthshore hospital surgeon, Bill, wants to build 3-sigma x- bar control limits for the open heart surgery. The target value for the mean of the process (x-bar) is 10 units, and the standard deviation of the process is 8. If samples of size 16 are to be taken, what will be the upper and lower control limits, respectively? Question 33 options: 8 and 12 16 and 4 -8 and 28 18 and 6 16 and 4arrow_forwardSam’s Long Life 60-watt light bulbs are designed to have a life of 1,350 hours with tolerance of ± 340 hours. A recent representative sample from the process that makes these light bulbs revealed a mean of 1,290 hours, with a standard deviation of 94 hours. Compute a. Compute the process capability ratio and the process capability index, and comment on the overall capability of the process b. Explain to what extent the process for producing Sam’s Long Life 60-watt light bulbs would have to be improved to achieve 4-sigma quality. c. show detail workarrow_forward

- An X-bar chart has the following control limits UCL=251.5 and LCL=248.5. The sample size is n=4, the process mean is equal to 250 and the process standard deviation is sigma = 1.0. What is the Cp value ? 0.500 not enough information 0.316 0.408 0.447 0.353arrow_forwardAt Quick Car Wash, the wash process is advertised to take less than 7 minutes. Consequently, management has set a target average of 390 seconds for the wash process. Suppose the average range for a sample of 9 cars is 8 seconds. Use the accompanying table to establish control limits for sample means and ranges for the car wash process. LOADING... Click the icon to view the table of factors for calculating three-sigma limits for the x overbarx-chart and R-chart. Factors for calculating three-sigma limits for the x overbarx-chart and R-chart Size of Sample (n) Factor for UCL and LCL for x overbarx-chart (Upper A 2A2) Factor for LCL for R-Chart (Upper D 3D3) Factor for UCL for R-Chart (Upper D 4D4) 2 1.8801.880 00 3.2673.267 3 1.0231.023 00 2.5752.575 4 0.7290.729 00 2.2822.282 5 0.5770.577 00 2.1152.115 6 0.4830.483 00 2.0042.004 7 0.4190.419 0.0760.076 1.9241.924 8 0.3730.373…arrow_forwardAt Quick Car Wash, the wash process is advertised to take less than 6 minutes. Consequently, management has set a target average of 320 seconds for the wash process. Suppose the average range for a sample of 10 cars is 10 seconds. Use the accompanying table to establish control limits for sample means and ranges for the car wash process.arrow_forward

- The output of a certain integrated-circuit productionline is checked daily by inspecting a sample of 100 units.Over a long period of time, the process has maintaineda yield of 80 percent, that is, a proportion defective of 20 percent, and the variation of the proportion defec-tive from day to day is measured by a standard devi-ation of 0.04. If on a certain day the sample contains 38 defectives, find the mean of the posterior distribu-tion of as an estimate of that day’s proportion defec-tive. Assume that the prior distribution of Θ is a beta distribution.arrow_forwardThe Canine Gourmet Company produces delicious dog treats for canines with discriminating tastes. Management wants the box-filling line to be set so that the process average weight per packet is 45 grams. To make sure that the process is in control, an inspector at the end of the filling line periodically selects a random box of 10 packets and weighs each packet. When the process is in control, the range in the weight of each sample has averaged 5 grams. Click the icon to view the table of factors for calculating three-sigma limits for the x-chart and R-chart. a. Design an R- and an x-chart for this process. The UCLR equals 8.89 grams and the LCLR equals 1.12 grams. (Enter your response rounded to two decimal places.) The UCL equals 46.54 grams and the LCL equals 43.46 grams. (Enter your responses rounded to two decimal places.) b. The results from the last 5 samples of 10 packets are shown below. Is the process in control? Explain. The process variability is in Sample 1 2 3 4 5…arrow_forwardIn process industry during a daily production run, a total of five (05) samples are collected with four (04) observations within each sample. The sample means (X-bar) are; 14.09, 13.94,16.86, 20.00, and 16.64 respectively. The corresponding ranges are; 9.90, 7.73, 4.41, 7.56, and 3.49 respectively. The lower and upper control limits of the x-bar chart are respectively O a. 11.44, 20.66 O b. 11.29, 20.65 C. None is correct Od. 11.47, 21.14 e. 11.47, 16.55arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.