Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

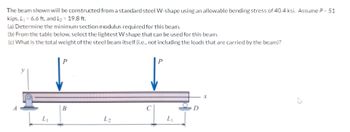

The beam shown will be constructed from a standard steel W-shape using an allowable bending stress of 40.4 ksi. Assume P = 51 kips, L1=6.6 ft, and L2=19.8 ft.

(a) Determine the minimum section modulus required for this beam.

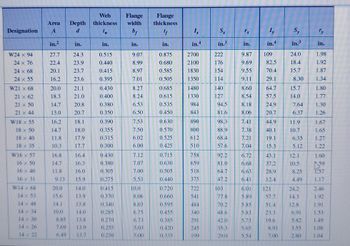

(b) From the table below, select the lightest W shape that can be used for this beam.

(c) What is the total weight of the steel beam itself (i.e., not including the loads that are carried by the beam)?

Transcribed Image Text:The beam shown will be constructed from a standard steel W-shape using an allowable bending stress of 40.4 ksi. Assume P = 51

kips, L₁ = 6.6 ft, and L₂ = 19.8 ft.

(a) Determine the minimum section modulus required for this beam.

(b) From the table below, select the lightest W shape that can be used for this beam.

(c) What is the total weight of the steel beam itself (i.e., not including the loads that are carried by the beam)?

L₁

P

B

L2

с

P

L₁

-D

X

A

Transcribed Image Text:Designation A

W24 x 94

24 × 76

24 × 68

24 × 55

W21 x 68

21 x 62

21 x 50

21 x 44

W18 x 55

18 x 50

18 × 40

18 x 35

W16 x 57

16 x 50

16 x 40

16 x 31

Area Depth

d

W14 × 68

14 × 53

14 x 48

14 × 34

14 x 30

14 x 26

in.2

27.7

22.4

20.1

16.2

20.0

18.3

14.7

13.0

16.2

14.7

11.8

10.3

16.8

14.7

11.8

in.

24.3

23.9

23.7

23.6

20.0

15.6

14.1

10.0

21.1

21.0

20.8

20.7

16.4

16.3

16.0

9.13 15.9

18.1

18.0

17.9

17.7

14.0

13.9

13.8

14.0

8.85

13.8

7.69

13.9

6.49 13.7

Web

thickness

tw

in.

0.515

0.440

0.415

0.395

0.430

0.400

0.380

0.350

0.390

0.355

0.315

0.300

0.430

0.380

0.305

0.275

0.415

0.370

0.340

0.285

0.270

0.255

0.230

Flange

width

bf

in.

9.07

8.99

8.97

7.01

8.27

8.24

6.53

6.50

7.53

7.50

6.02

6.00

7.12

7.07

7.00

5.53

10.0

8.06

8.03

6.75

6.73

5.03

5.00

Flange

thickness

tr

in.

0.875

0.680

0.585

0.505

0.685

0.615

0.535

0.450

0.630

0.570

0.525

0.425

0.715

0.630

0.505

0.440

0.720

0.660

0.595

0.455

0.385

0.420

0.335

Ix

in.4

2700

2100

1830

1350

1480

1330

984

843

890

800

612

510

758

659

518

375

722

541

484

340

291

245

199

Sx

in.3

222

176

154

114

140

127

94.5

81.6

98.3

88.9

68.4

57.6

92.2

81.0

64.7

47.2

103

77.8

70.2

48.6

42.0

35.3

29.0

in.

9.87

9.69

9.55

9.11

8.60

8.54

8.18

8.06

7.41

7.38

7.21

7.04

6.72

6.68

6.63

6.41

6.01

5.89

5.85

5.83

5.73

5.65

5.54

Ty

in.4

109

82.5

70.4

29.1

64.7

57.5

24.9

20.7

44.9

40.1

19.1

15.3

43.1

37.2

28.9

12.4

121

57.7

51.4

23.3

19.6

8.91

7.00

Sy

in.3

24.0

18.4

15.7

8.30

15.7

14.0

7.64

6.37

11.9

10.7

6.35

5.12

12.1

10.5

8.25

4.49

24.2

14.3

12.8

6.91

5.82

3.55

2.80

Ty

in.

1.98

1.92

1.87

1.34

1.80

1.77

1.30

1.26

1.67

1.65

1.27

1.22

1.60

1.57

1.17

2.46

1.92

1.53

1.49

1.08

1.04

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Need neat and clean handwritten solution. Do remember for an upvote.arrow_forwardFor the eccentric loaded beam shown, determine the following:(a)Calculate the axial stress(b)Calculate the bending stress in the top and bottom layers of the beam(c)Determine the combined stress and sketch the combined stress profile in the beam sectionarrow_forwardDraw the shear-force and bending-moment diagram for the beam shown. Assume the upward reaction provided by the ground to be uniformly distributed. Let a = 5.0 ft, b = 3.4 ft, P = 25 kips, and w = 1.1 kips/ft. Label all significant points on each diagram. Determine the maximum value of (a) the internal shear force and (b) the internal bending moment.Note that answers may be positive or negative. Here, "maximum" refers to the largest magnitude value, but you should enter your shear force and bending moment with the correct sign, using the sign convention presented in Section 7.2 of the textbook. If the magnitudes of the largest positive and largest negative values are the same, enter a positive number.arrow_forward

- A 6 ft long 2” x 12” beam is subjected to a uniform (edge-to-edge) distributed load of 1500 lbs per linear foot. The material has a Young's Modulus E=2,000,000psi. If the allowed bending stress is 2000 psi, the allowed deflection is L/360 and the allowed shear stress is 250 psi: Is the beam safe in bending? Is the beam safe in deflection for L/360, ( deflDIST = (5 w L4)/(384 E I)? Is the beam safe in shear?arrow_forwardI am unsure how to start this problem. How do I solve it? Thanks!arrow_forwardFor the beam shown, use only singularity functions. V₁ = 45 lbf/in and V/₂ = 5 in. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. 0 1400 lbf Hinge JA B₁ C R₂ R₁ 4 in 4 in 2 in V1 V2 D R₂ + What is the value of the peak moment between points Cand D? The peak moment between points C and Dis Ibf.in.arrow_forward

- Note:- • Do not provide handwritten solution. Maintain accuracy and quality in your answer. Take care of plagiarism. • Answer completely. • You will get up vote for sure.arrow_forwardDetermine the ratios of the weights of four beams that have same length.are made of the same material,are subjected to the same lmaximum bending moment,and have the same maximum bending stress if their cross sections are (I) a rectangle with height equal to twice the width,(2) a square,(3) a circle , and (4) a pipe with outer diameter d and wall thickmess f = di% (see figures).arrow_forwardpart c and darrow_forward

- A double tee cross section is used for the beam shown below. Assume the following lengths and loads: a = 16 ft b = 8 ft c = 12 ft P= 9000 lb Q = 3000 Ib The moment of inertia of the cross section is l, = 110 in.“. Determine the magnitude (i.e., the absolute value) of the maximum tensile bending stress in the beam. 3.2 in. B C D 5.8 in. Answer: Omax (Tension) : i psiarrow_forwardThe figure below shows the cross-section of an axisymmetric composite beam that comprises steel (Young's modulus 270 GPa) and aluminum (Young's modulus 90 GPa) sections that are bonded together. The steel section is of wall thickness 15 mm and the aluminum section is of wall thickness 10mm. The steel section comprises 4 axisymmetric holes of 5 mm diameter as shown. Given that the beam is bent by a couple moment of 1200 Nm, determine the maximum stress in steel and aluminum. 4 holes of diameter 5 mm. 12 mm steel aluminumarrow_forwardFor certain values of w and P, the maximum positive bending moment in the beam is +8840 lb-ft, and the maximum negative bending moment is-10336 lb-ft. The cross section of the beam is shown. The pertinent section properties of the cross section are e = 4.65 in..f -3.05 in, and I, - 13.7725 in.. Calculate (a) the maximum tensile bending stress and (b) the maximum compressive bending stress that is produced in the beam. Enter your answers with the appropriate sign. A Answer: Of= gc d B b tik psi psi C Darrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY