Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

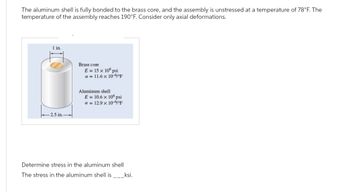

Transcribed Image Text:The aluminum shell is fully bonded to the brass core, and the assembly is unstressed at a temperature of 78°F. The

temperature of the assembly reaches 190°F. Consider only axial deformations.

1 in.

-2.5 in.

Brass core

E = 15 x 106 psi

a = 11.6 × 10-6°F

Aluminum shell

E = 10.6 × 106 psi

a = 12.9 x 10-6°F

Determine stress in the aluminum shell

The stress in the aluminum shell is ____ksi.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- A thick-walled cylindrical pressure vessel with an inside diameter of 280 mm and an outside diameter of 430 mm is made of a steel that has a yield strength of 420 MPa. Determine the maximum internal pressure that may be applied to the vessel if a factor of safety of 3.3 with respect to failure by yielding is required. Part 1 Determine the maximum allowable tensile stress in the vessel wall. Answer: Oallow i MPaarrow_forwardThe assembly shown consists of an aluminum shell (E, = 70 GPa, az= 23.6 x 10-6PC) fully bonded to a steel core (Es= 200 GPa, as = 11.7 x 10 0rC) and the assembly is unstressed at a temperature of 20°C. Considering only axial deformations, determine the stress in the aluminum when the temperature reaches 210°C. 200 mm 20 mm Aluminum shell Steel 50 mm core The stress in the aluminum is |MPa.arrow_forwardRequired information The aluminum shell is fully bonded to the brass core, and the assembly is unstressed at a temperature of 78°F. The temperature of the assembly reaches 175F. Consider only axial deformations. 1 in. Brass core E = 15 x 10° psi a = 11.6 x 10-6/°F Aluminum shell E = 10.6 x 106 psi a = 12.9 x 10-6/°F -2.5 in. Determine the stress in the brass core. The stress in the brass core is ksi.arrow_forward

- Determine the allowable stress in last example if the factor of safety is 2.5.arrow_forwardwith the free body diagramsarrow_forwardA tension test was performed on a steel specimen having an original diameter of 12.5 mm and gauge length of 50 mm. The data is listed in the table. Plot the stress–strain diagram and determine approximately the modulus of elasticity, the yield stress, the ultimate stress, and the rupture stress. Use a scale of 25 mm = 140 MPa and 25 mm = 0.05 mm/mm. Redraw the elastic region, using the same stress scale but a strain scale of 25 mm = 0.001 mm/mm.arrow_forward

- The 10-mm-diameter steel bolt in (Figure 1) is surrounded by a bronze sleeve . The outer diameter of this sleeve is 20 mm, and its inner diameter is 10 mm. Est = 200 GPa, Epr 100 GPa. Part A If the bolt is subjected to a compressive force of P = 15.7 kN, determine the average normal stress in the steel. Express your answer to three significant figures and include appropriate units. Ost = Value MPа Submit Request Answer Part B If the bolt is subjected to a compressive force of P = 15.7 kN, determine the average normal stress in the bronze. Express your answer to three significant figures and include appropriate units. Figure HA P Obr = Value MPа Submit Request Answer 10 mm Provide Feedback 20 mm Parrow_forwardThe principal plane stresses and associated strains in a 35 ksi, 02 = 15 ksi, plane at a point are 01 1 €1 = 1.02(10-3), 2 = 0.180(10-³). ▼ Determine the modulus of elasticity. Express your answer using three significant figures and include the appropriate units. E= Submit Part B V= μA Value Request Answer Submit Determine the Poisson's ratio. Express your answer using three significant figures. ΠΑΠΙ ΑΣΦ | Η VE Units Request Answer ? vec POSSIA space ?arrow_forwardDetermine the principal stresses at points A and B of the cylinder. Consider: L = 70 mm; d = 20 mm; F = 12 kN; P = 15 kN; T = 800 Nm.arrow_forward

- The assembly has the diameters and material make-up indicated. It fits securely between its fixed supports when the temperature is T₁ = 70°F. (Figure 1) this is all the information given. Figure 2014-T6 Aluminum 12 in. -C 86100 Bronze 8 in. 6 ft 304 Stainless steel- C₁ 4 in. 3 ft 1 of 1 Part A Determine the average normal stress in the aluminum when the temperature reaches T₂ = 124 °F. Express your answer to three significant figures and include the appropriate units. σal = Submit Part B The Submit Part C Determine the average normal stress in the bronze when the temperature reaches T₂ = 124 °F. Express your answer to three significant figures and include the appropriate units. Tyt HA Value Submit Request Answer μà Value Request Answer Value Units Determine the average normal stress in the stainless steel when the temperature reaches T₂ = 124 °F. Express your answer to three significant figures and include the appropriate units. Request Answer Units ? www ? Units ?arrow_forward1arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY