Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

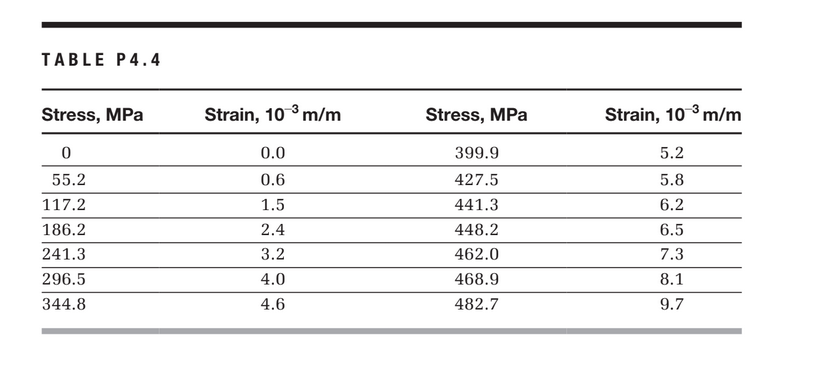

An aluminum alloy bar with a radius of 7 mm was subjected to tension until fracture and produced results shown in Table P4 a. Using a spreadsheet program, plot the stress–strain relationship. b. Calculate the modulus of elasticity of the aluminum alloy. c. Determine the proportional limit. d. What is the maximum load if the stress in the bar is not to exceed the proportional limit? e. Determine the 0.2% offset yield strength. f. Determine the tensile strength. g. Determine the percent of elongation at failure.

Transcribed Image Text:TABLE P4.4

Stress, MPa

Strain, 10 3 m/m

Stress, MPa

Strain, 10 3 m/m

0.0

399.9

5.2

55.2

0.6

427.5

5.8

117.2

1.5

441.3

6.2

186.2

2.4

448.2

6.5

241.3

3.2

462.0

7.3

296.5

4.0

468.9

8.1

344.8

4.6

482.7

9.7

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- 1. The tensile strength vs. temperature curves of aluminum are plotted below. Explain the meaning of these two curves. 400 Ultimate strength 300 Yield strength 200 100 -200 -150 -100 -50 50 100 150 200 250 Temperature, °C Strength, kPaarrow_forwardA steel specimen is tested in tension. The specimen is 25 mm wide by 12.5 mm thick in the test region. By monitoring the load dial of the testing machine, it was found that the specimen yielded at a load of 160 kN and fractured at 214 kN. a. Determine the tensile stress at yield and at fracture. b. If the original gauge length was 100 mm, estimate the gauge length when the specimen is stressed to 1/2 the yield stress.arrow_forwardA steel component is subjected to alternate cyclical loading. The steel follows Basquin's law for high cycle fatigue, o, x N = C, (where the stress amplitude is in MPa). Ignore the geometric detail and assume that Marin's modifying factors are all equal to 1. You are given the minimum stress ain = -213 MPa, the maximum stress omax = 213 MPa. The material data are Tensile strength oUTS = 539 MPa, Basquin's constant c, = 875 MPa, Basquin's exponent a = 0.085. a) Calculate the stress ratio R, the stress amplitude o, in MPa and the mean stress am in MPa. The answers are acceptable with a tolerance of 0.01 for R and of 1 MPa the stresses. R: MPa MPа b) Calculate the corresponding life, in 10° cycles, (tolerance of 0.1 106 cycles) N :arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning