Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

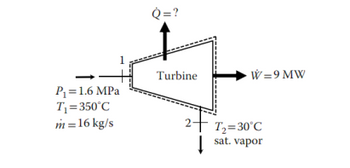

Steam at 1.6 MPa and 350°C enters a steam turbine at a flow rate of 16 kg/s. The

steam leaves the turbine as a saturated vapor at 30°C. The turbine delivers 9 MW of

power. A schematic of the turbine and its operating conditions are given in the

Figure below. Determine the heat transfer rate from this turbine.

Transcribed Image Text:P₁ = 1.6 MPa

T₁

= 350°C

m = 16 kg/s

Q=?

Turbine

↓

W = 9 MW

T₂=30°C

sat. vapor

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- You are designing an electric air heater for large conference rooms. A 75mm OD, 4mm wall thickness intake pipe sucks air into the unit at 2 m/s. The air passes over a 3m long heater coil and is exhausted at a temperature of 38degC. What is the average heat rate of the heater coil into the air?arrow_forwardRefrigerant 22 at a pressure of 1500 kPa leaves the condenser and rises vertically11 m to the expansion valve. The pressure drop due to friction in the liquid line is21 kPa. In order to have no vapor in the refrigerant entering the expansion valve,what is the maximum allowable temperature at that point?arrow_forward1. Refrigerant 134-a enters a compressor at 180kPa as a saturated vapor with a flow rate of 0.4m³/min and leaves at 700kPa. The power supplied to the refrigerant during the compression process is 2.5kW. What is the temperature of the refrigerant at the exit of the compressor?arrow_forward

- Water flows through two adiabatic turbines and a heat exchanger as shown in the picture. Hot air is used to provide additional energy to the water between the two turbines. The first turbine has a power output of 8,000 kW. Determine the power output of the second turbine in kW and the process efficiency of each turbine. Determine the state of steam in turbine 1, Formulate the 1st Law for turbine 1, and solve for the flow rate of steam. Formulate the 1st Law for the heat exchanger, and solve for the temperature at exitarrow_forwardIn an adiabatic turbine, this steam flow is 50 kg / s. The power produced by the turbine is 29 MW.Steam enters the turbine with a pressure of 50 bar and a speed of 60 m / s. At the outlet, at a pressure of 0.06 barIt comes out as saturated water with a speed of 130 m / s. Accordingly, the heat lost by the turbine andFind the turbine inlet and outlet temperatures of steamarrow_forwardA steam plant. the pressure levels are 10 kPa and 6000 kPa, and the steam leaves the turbine as saturated vapor. The pump efficiency is 0.70 and the turbine 0.75. determine the thermal efficiency of the plantarrow_forward

- The change of enthalpy of air in the cooling tower is 82 kJ/ kg and the mass flow of air is 215 kg/ min. Water enters the tower at the rate of 55 gpm at 46°C.A.) Calculate the exit temperatureB.) Determine the efficiency of the tower if the approach is 8.81°C.arrow_forwardFor air properties use online source: https://www.peacesoftware.de/einigewerte/luft_e.html The compressor is operating at steady-state increasing pressure of R-22 refrigerant from 4 bars to 14 bars. Temperature was rising during the process from 12C to 90C. The inlet volumetric flow rate is 1 m3/min and inlet diameter is 0.03m. At the exit the diameter is the same. Heat flow to the surroundings can be neglected. Determine: a.Mass flow rate [kg/s] b. Inlet and outlet velocity [m/s] c.Power required to run the compressor [kW]arrow_forwardSolve the following problem and show your complete solutions for better understanding.arrow_forward

- A steam turbine operates with 1.6 MPa and 350 deg C steam at its inlet and saturated vapor at 30 deg C at its exit. The mass flow rate of the steam is 22 kg/s, and 610.2 kW of heat is lost through the casing of the turbine. 1. Create a sketch of the problem and indicate the control volume. 2. Write the continuity and energy equations and cross out terms by stating the relevant steady state assumptions. 3. Determine power produced. 4. Determine the specific work.arrow_forwardplease help mearrow_forwardAir (R = 0.3074 psia.cf/lbm.R) is compressed from 14.7 psia and 60°F to a pressure of 150 psia while heat loss rate during the steady compression is 10 Btu/lbm. The volume flow rate of the air at the inlet is 5,000 ft'/min and the power input to the compressor is 700 hp. Determine the temperature at the compressor exit in °F. (1hp = 0.7068 Btu/s) AIR %3D 10 Bru Ibmarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY