Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

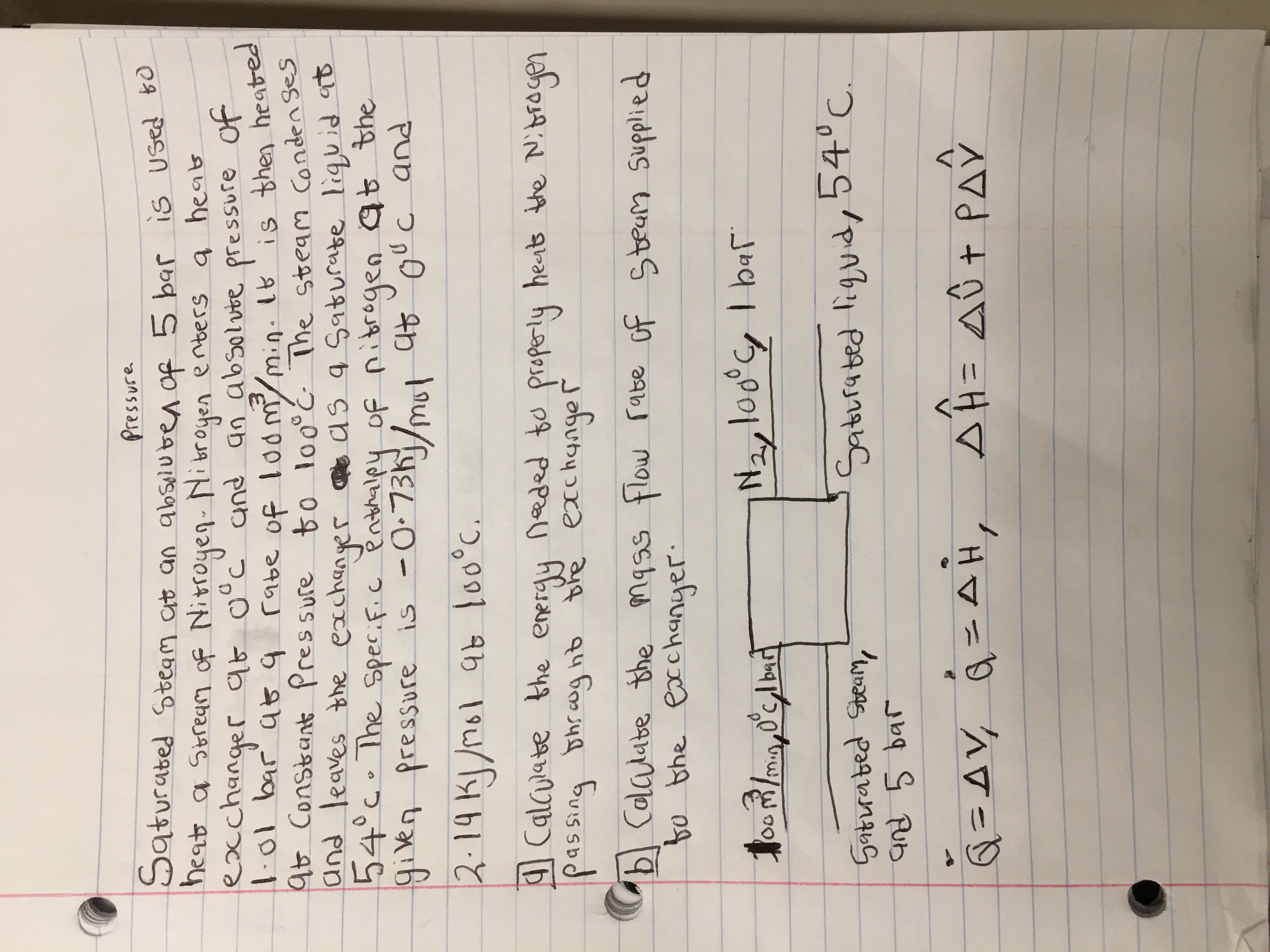

Transcribed Image Text:Saturated Steam ait an abseluben of 5 bar is Used 0

heat a Stream of Nitroyen- Nibroyen enters a heas

exchanger 9t 0°c° und an absolute pressure of

l01 bar at q rabe of loom/min: 18'is then heated

45 Constant Pressure to loa°ć- The steam Conden ses

and leaves the exchanger

54°c.The specif.c enthalpy of nibrogen at the

given pressure is -0:73h/mut at°ouc and

e as q Saturate liquid 9o

2.19K/ol 9b lo0°C.

Transcribed Image Text:TABLE B.6 Properties of Saturated Steam: Pressure Table

V(m³/kg)

Û (kJ/kg)

Ĥ (kJ/kg)

P(bar)

T(°C)

Water

Steam

Water

Steam

Water

Evaporation

Steam

0.001000

0.001000

2375.6

2380.7

+0.0

2501.6

2508.5

0.00611

0.01

3.8

206.2

159.7

zero

2501.6

0.008

15.8

15.8

2492.6

0.010

129.2

108.7

93.9

7.0

0.001000

29.3

2385.2

29.3

2485.0

2514.4

2478.7

2473.2

0.012

9.7

0.001000

40.6

2388.9

40.6

2519.3

0.014

12.0

0.001000

50.3

2392.0

50.3

2523.5

0.016

0.018

14.0

0.001001

82.8

58.9

2394.8

58.9

2468.4

2527.3

15.9

0.001001

74.0

66.5

2397.4

66.5

2464.1

2530.6

0.020

0.022

0.024

0.026

17.5

2399.6

2401.7

2403.6

0.001001

67.0

73.5

73.5

2460.2

2533.6

61.2

56.4

19.0

0.001002

79.8

79.8

2456.6

2536.4

20.4

21.7

0.001002

85.7

85.7

2453.3

2539.0

0.001002

52.3

91.1

2405.4

91.1

2450.2

2541.3

0.028

23.0

0.001002

48.7

96.2

2407.1

96.2

2447.3

2543.6

0.030

0.035

0.001003

101.0

111.8

2408.6

2412.2

2415.3

101.0

111.8

2545.6

2550.4

24.1

45.7

2444.6

26.7

0.001003

39.5

2438.5

0.040

29.0

0.001004

34.8

121.4

121.4

2433.1

2554.5

0.045

0.050

130.0

137.8

2428.2

2423.8

0.001005

130.0

2418.1

2558.2

2561.6

31.0

31.1

32.9

0.001005

28.2

137.8

2420.6

151.5

163.4

0.060

36.2

0.001006

23.74

2425.1

151.5

2416.0

2567.5

0.070

0.080

0.090

163.4

173.9

183.3

2409.2

39.0

41.5

43.8

0.001007

20.53

2428.9

2572.6

0.001008

0.001009

18.10

16.20

14.67

2432.3

2435.3

2438.0

2403.2

2397.9

173.9

183.3

191.8

2577.1

2581.1

2584.8

0.10

45.8

0.001010

191.8

2392.9

0.11

47.7

0.001011

13.42

199.7

2440.5

199.7

2388.4

2588.1

12.36

11.47

10.69

206.9

213.7

220.0

49.4

2442.8

2445.0

2447.0

206.9

2384.3

2591.2

2594.0

2596.7

0.12

0.001012

0.001013

0.001013

0.13

51.1

213.7

2380.4

0.14

52.6

220.0

2376.7

Appendix B Physical Property Tables 645

226.0

231.6

236.9

0.15

54.0

0.001014

10.02

2448.9

226.0

2373.2

2599.2

9.43

8.91

8.45

8.03

0.16

55.3

56.6

0.001015

2450.6

231.6

2370.0

2601.6

2452.3

2453.9

0.001015

2366.9

2603.8

0.17

0.18

236.9

0.001016

242.0

246.8

2363.9

2605.9

2607.9

57.8

242.0

0.19

59.0

0.001017

246.8

2455.4

2361.1

0.001017

0.001018

0.001019

251.5

260.1

268.2

2456.9

2459.6

2462.1

251.5

260.1

268.2

275.7

282.7

2358.4

2353.3

2348.6

0.20

60.1

7.65

2609.9

2613.5

2616.8

2619.9

2622.7

0.22

62.2

7.00

0.24

64.1

6.45

0.26

65.9

0.001020

5.98

275.6

2464.4

2344.2

0.28

67.5

0.001021

5.58

282.7

2466.5

2340.0

0.001022

0.001025

5.23

4.53

0.30

2336.1

2327.2

2319.2

2312.0

2305.4

69.1

289.3

2468.6

289.3

2625.4

0.35

72.7

304.3

2473.1

304.3

2631.5

75.9

3.99

317.6

2477.1

317.7

2636.9

2641.7

2646.0

0.40

0.001027

0.001028

0.45

0.50

78.7

81.3

329.6

340.5

3.58

2480.7

329.6

0.001030

3.24

2484.0

340.6

350.6

359.9

2649.9

0.55

0.60

0.001032

0.001033

0.001035

83.7

2.96

350.6

359.9

2486.9

2299.3

86.0

88.0

2.73

2.53

2489.7

2492.2

2293.6

2288.3

2283.3

2653.6

0.65

368.5

368.6

2656.9

376.7

384.4

0.70

90.0

0.001036

2.36

2494.5

376.8

2660.1

0.75

91.8

0.001037

2.22

2496.7

384.5

2278.6

2663.0

0.80

0.85

0.90

391.6

398.5

405.1

2.087

2498.8

2500.8

93.5

0.001039

2274.1

391.7

398.6

405.2

2665.8

95.2

0.001040

1.972

2269.8

2668.4

96.7

0.001041

0.001042

1.869

2502.6

2265.6

2670.9

2673.2

0.95

98.2

1.777

411.4

2504.4

411.5

2261.7

1.00

1.01325

(1 atm)

99.6

417.5

2257.9

2675.4

0.001043

0.001044

1.694

417.4

2506.1

100.0

1.673

419.0

2506.5

419.1

2256.9

2676.0

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Calculate the heat capacity for formaldehyde at 25°C. Answer should be in kJ/kgmol°Carrow_forwardA sulfur burner, burning sulfur of 98% purity with dry air, discharged gas at 1300°F containing 16% SO2, 5% O2, and 79% N2. Both the sulfur and the air supplied are at 80°F. The heat of combustion of sulfur to SO2 is 127690 BTU/lbmole at 25°C. The burner gas is mixed with more dry air (secondary air) and passed through a converter. Analysis of the converter gas shows 4.2% SO2, 7.5% O2 and 88.3% N2. An absorber subsequently removes 95% of the SO3 in the converter gas by absorbing it in 97% H2SO4 to produce 100% H2SO4 solution. No SO3 is formed in the absorber. a. Calculate the volume of secondary air supplied at 80°F and 735 mmHg per 100 lbs impure sulfur entering.b. How many pounds of 97% H2SO4 solution must be supplied per mole of SO3-free converter gas?arrow_forwardExample. 6.3.How much heat has to be added to a solution of 1g mol of HCl in H2O to concentrate the solution to 1 g mol of HCl in 4 g mol of H,0? g mol ofarrow_forward

- 6.4% CO2, 0.2% 02, 0, 40% CO at 500 C. 50.8% H2. and 200 gmol of synthesis gas, the remainder being Na, is burned with 40% excess dry air at 25 C. It is known that combustion gases exit the chimney at a temperature of 720 C. Determine the mole amounts of the exiting flue gases and the heat transfer from or to the combustion process.arrow_forward1:02 AM ll Verizon 99%- Done 4. The enthalpy of vaporization of water at 100 °C is 2256.9 kJ/Kg. Assuming an average heat capacity for liquid water and heat capacity of vapor calculate the heat of vaporization at 25 °C. At 25 °C the vapor pressure of water is 23.756 mm Hg.arrow_forwardThe purge gases from a synthetic ammonia plant contain 4% ammonia by volume and 96% hydrogen, nitrogen, argon and other inerts. This gas is to be scrubbed at 5 atmosphere pressure with water in a bubble plate tower maintained at 68°F by cooling coils. With water and inert gas rates of 0.88 and 4 lb/min ft2 of tower cross section respectively, how many theoretical plates will be required to produce a solution containing 13% ammonia by weight? The average molecular weight of the inert gas is 21. Data: the following gives the equilibrium partial pressure of ammonia solutions at 68°F 69.6 166 5 10 Partial pressure, torr 12 Pound NH3/100 gram H2O 1 19.2 31.7 1.5 5 50 3.75arrow_forward

- A sulfur bumer, burning sulfur of 98% purity with dry air, discharged gas at 1300°F containing 16% SO2, 5% O2, and 79% Na. Both the sulfur and the air supplied are at 80°F. The heat of combustion of sulfur to SO, is 127690 BTU/Ibmole at 25°C. The burner gas is mixed with more dry air (secondary air) and passed through a converter. Analysis of the converter gas shows 4.2% SO2, 7.5% Oz and 88.3% Na. An absorber subsequently removes 95% of the SOs in the converter gas by absorbing it in 97% H,SO, to produce 100% H,SO. solution. No SOs is formed in the absorber. a. Calculate the volume of secondary air supplied at 80°F and 735 mmHg per 100 lbs impure sulfur entering. b. How many pounds of 97% HaSO. solution must be supplied per mole of SO3-free converter gas?arrow_forwardI need the answer as soon as possiblearrow_forward2 A triple-acting evaporator with direct current power must concentrate 15000 kg/h of an aqueous solution entering 25 C from 10% to 40% by weight. For the heating is available live steam at 2.2 at, and on the third effect a vacuum is maintained that allows the solution to boil at 30ºC. The dissolution does not present an appreciable increase in the point of boiling and its specific heat is equal to the unit for all concentrations. The integral heat transmission coefficients for effects I, II, III, in Kcal/m2*h*ºC, they are worth 2800, 2500 and 1600. Apply to each effect: a) Hourly consumption of heating steam b) Boiling temperature c) The heating surface.arrow_forward

- A fruit juice at 20°C with 5% total solids is being concentratedin a single-effect evaporator. The evaporator is being operatedat a suffi cient vacuum to allow the product moisture to evaporate at 80°C, and steam with 85% quality is being supplied at 169.06 kPa. The desired concentration of thefi nal product is 40% total solids. The concentrated productexits the evaporator at a rate of 3000kg/h. Calculate the(a) steam requirements and (b) steam economy for theprocess, when condensate is released at 90°C. The specifi cheat of liquid feed is 4.05kJ/(kg°C), and of concentratedproduct is 3.175kJ/(kg°C). A single-effect evaporator is being used to concentrate10,000 kg/h of tomato juice from 5% total solids to 30% totalsolids. The juice enters the evaporator at 15°C. The evaporatoris operated with steam (80% quality) at 143.27 kPa. Thevacuum inside the evaporator allows the juice to boil at 75°C.Calculate (a) the steam requirements and (b) steam economyfor the process. Assume the…arrow_forwardThe result of air temperature measurement obtained dry ball temperature 37°C and wet ball temperature 27.5 °C. Using a graph of psychotry, determine the properties of the air as follows:a. RH : %B. Moisture content : kg of water / kg of airc. Specific volume : m3/kgd. Enthalpi : kJ/kgE. Condensation temperature : °CIf the air is within 162 m3 of space, specify theF. Weight of air (dry air and moisture) : Kgg. amount of water content in the room: kgarrow_forward2. It is desired to produce 10 kg.mol lime from calcinations of CaCO, (pure) in a rotary kiln. Producer gas of composition 7.2% CO,, 1.6% O, 16.6% CO and 74.6% N, is combusted with 20% excess air to obtain the desired temperature in the kiln. The limestone and air are supplied at 298K, whereas producer gas is heated to 900K. Lime is discharged at 1200K and at 500K. Calculate the amount of the producer gas (latm and 273K).arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The