Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

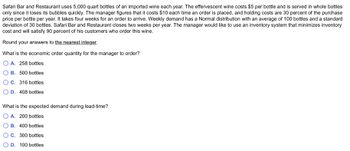

Transcribed Image Text:Safari Bar and Restaurant uses 5,000 quart bottles of an imported wine each year. The effervescent wine costs $5 per bottle and is served in whole bottles

only since it loses its bubbles quickly. The manager figures that it costs $10 each time an order is placed, and holding costs are 30 percent of the purchase

price per bottle per year. It takes four weeks for an order to arrive. Weekly demand has a Normal distribution with an average of 100 bottles and a standard

deviation of 30 bottles. Safari Bar and Restaurant closes two weeks per year. The manager would like to use an inventory system that minimizes inventory

cost and will satisfy 90 percent of his customers who order this wine.

Round your answers to the nearest integer.

What is the economic order quantity for the manager to order?

A. 258 bottles

B. 500 bottles

C. 316 bottles

D. 408 bottles

What is the expected demand during lead-time?

A. 200 bottles

B. 400 bottles

C. 300 bottles

D. 100 bottles

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- 7. Sam's Cat Hotel operates 52 weeks per year, 5 days per week, and uses a continuous review inventory system. It purchases kitty litter for $11.00 per bag. The following information is available about these bags. Refer to the standard normal table for z-values. ≻Demand = 95 bags/week ≻Order cost = $57/order ≻Annual holding cost = 30 percent of cost ≻Desired cycle-service level=98 percent ≻Lead time = 1 week(s) (5 working days) ≻Standard deviation of weekly demand = 20 bags ≻Current on-hand inventory is 350 bags, with no open orders or backorders. d. The store currently uses a lot size of 490 bags (i.e., Q=490). What is the annual holding cost of this policy? (Enter your response rounded to two decimal places.) and (Enter your response rounded to two decimal places.) **select the correct multiple choice answer** e. What would be the annual cost saved by shifting from the 490-bag lot size to the EOQ? (Enter your responses rounded to two decimal places.)arrow_forwardA certain successful entrepreneur purchases high-quality term papers ("guaranteed A") from an even bigger entrepreneur for resale to unethical students. Annual demand is 34000 papers, carrying cost is $3 per paper per year, and ordering cost is $90 per order. Students, being as desperate as they are, never backorder. The purchase price is stiff $35 per paper. What is the optimal order quantity (round your final answer to the nearest integer) ?MY answer 1428Correct answer 1565arrow_forwardExplain concepts of inventory like carrying costs, ordering costs, inventory models.arrow_forward

- Retail business's inventory includes goods in process and raw material. True Falsearrow_forwardMichigan State figurines Inc. sells Crystal figurines to spartan fans. They buy the figurines from the manufacture for $19 per unit. They send orders electronically to the manufacturer, cost and $33 per order and they experience an average sleep time of six days for each order to arrive from the manufacture. Their inventory Karen cost is 20%. The average daily demand for the figurines is two units per day. They are open for business 250 days a year. Answer the following questions. I am struggling with the last two.arrow_forwardThomas Kratzer is the purchasing manager for the headquarters of a large insurance company chain with a central inventory operation. Thomas’s fastest-moving inventory item has a demand of 6,000 units a year. The purchasing cost of each unit is $16 (additional 5% discount applies if at lease 150 units ordered a time), and the inventory carrying cost is $3 per unit per year. The average ordering cost is $10 per order. It takes about 3 working days for an order to arrive. (This is a corporate operation, and there are 300 working days per year.) Answer the following questions, Q1~Q5. Note that you must include Excel formulas/calculations showing how you arrive at the answer. Q1: Assume that the demand is consistent throughout the year. What is the ROP? Note that stockouts and unnecessary inventory holding should be avoided at any times. Q2: Assume that the demand is consistent throughout the year. Based on the EOQ model, to minimize the costs of purchasing, ordering and inventory holding…arrow_forward

- Potter Machine Company expects total sales of $60,000. The price per unit is $10. The firm estimates an ordering cost of $25 per order, with an inventory carrying cost of $0.70 per unit. What is the optimal order size?arrow_forwardInvestigate the effects of demand variability on the overall effectiveness of the Wilson approach in inventory management.arrow_forwardYellow Press, Inc., buys paper in 1,500-pound rolls for printing. Annual demand is 3,000 rolls. The cost per roll is $1,000, and the annual holding cost is 28 percent of the cost. Each order costs $75. Part 2 a. How many rolls should Yellow Press order at a time? Yellow Press should order enter your response here rolls at a time. (Enter your response rounded to the nearest whole number.) Part 3 b. What is the time between orders? (Assume 200 workdays per year.) The time between orders is enter your response here days. (Enter your response rounded to one decimal place.)arrow_forward

- Please do not give solution in image format thankuarrow_forwardRegional Supermarket is open 360 days per year. Daily use of cash register tape averages 10 rolls. Usage appears normally distributed with a standard deviation of 2 rolls per day. The cost of order-ing tape is $1, and carrying costs are 40 cents per roll a year. Lead time is three days. a. What is the EOQ?b. What ROP will provide a lead time service level of 96 percent?arrow_forwardEOQ, reorder point, and safety stock Alexis Company uses 916 units of a product per year on a continuous basis. The product has a fixed cost of $60 per order, and its carrying cost is $3 per unit per year. It takes 5 days to receive a shipment after an order is placed, and the firm wishes to hold 10 days' usage in inventory as a safety stock. a. Calculate the EOQ. b. Determine the average level of inventory. (Note: Use a 365-day year to calculate daily usage.) c. Determine the reorder point. d. Indicate which of the following variables change if the firm does not hold the safety stock: (1) order cost, (2) carrying cost, (3) total inventory cost, (4) reorder point, (5) economic order quantity. a. Alexis' EOQ is units. (Round to the nearest whole number.)arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.