Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

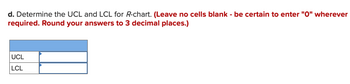

Transcribed Image Text:d. Determine the UCL and LCL for R-chart. (Leave no cells blank - be certain to enter "0" wherever

required. Round your answers to 3 decimal places.)

UCL

LCL

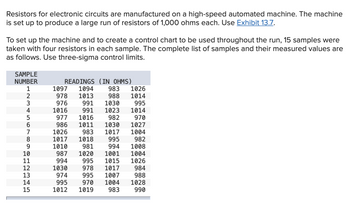

Transcribed Image Text:Resistors for electronic circuits are manufactured on a high-speed automated machine. The machine

is set up to produce a large run of resistors of 1,000 ohms each. Use Exhibit 13.7.

To set up the machine and to create a control chart to be used throughout the run, 15 samples were

taken with four resistors in each sample. The complete list of samples and their measured values are

as follows. Use three-sigma control limits.

SAMPLE

NUMBER

1

H234STO OHN345

5

6

7

8

9

10

11

ΕΕΕΕΕ

12

13

14

15

READINGS (IN OHMS)

1097 1094

978

1013

976

1016

977

986

983

1026

988 1014

991 1030

995

991

1023

1014

982

970

1030 1027

1017

1004

995

982

994

1008

1001

1004

995 1015

1026

978 1017

984

995

1007

988

970

1004 1028

1019

983

990

1026

1017

1010

987

994

1030

974

995

1012

1016

1011

983

1018

981

1020

Expert Solution

arrow_forward

Step 1

Formulae used:

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Similar questions

- Lay's potato chip filling process has a lower specification limit of 9.5 oz. and an upper specification of 10.5 oz. The mean is 10 oz. What should be the value for standard deviation in this process to achieve a ppm of 5110? A. 0.1786 B. 0.2675 OC. 0.4453 OD. 0.3564arrow_forwardControl charts for X-bar and S are maintained for the fill volume of protein shake drink. The specifications are 330 + 10 mL. After 40 samples of size n=7 are analyzed, we find that: 40 40 = 13,200 Si = 296 i=1 i=D1 Find the best estimate of the process standard deviation. 7.498 7.400 7.570 2.737 7.713 8.032arrow_forward60 pt 1 plz helparrow_forward

- A shirt manufacturer buys clothes by the 100-yard roll from a supplier. For setting a control chart to manage the irregularities (e.g., loose threads and tears), the following data were collected from a sample provided by the supplier. Sample 1 2 3 4 5 6 7 8 9 10 Irregularities 3 5 2 6 5 4 6 3 4 5 Which type of control chart should be used? Construct a control chart with two-sigma control limits. Suppose the next five rolls from the supplier had three, two, five, three, and seven irregularities. Is the supplier process under control? Explain and show workarrow_forwardA producer of windshields decides to monitor the material handling system used in the plant. The producer is concerned about if there are scratches that are appearing on their finished product. The best kind of control chart to use in this case is a: r chart b: x chart c: cpk chart d: P chartarrow_forwardThe smallest defect in a computer chip will render the entire chip worthless. Therefore, tight quality control measures must be established to monitor these chips. In the past, the percent defective at Chieh Lee's Computer Chips has been 1.5%. The sample size is 1,000. Determine upper and lower control chart limits for these computer chips. Use z = 3. Upper Control Limit (UCL) = (round your response to four decimal places). Lower Control Limit (LCLp) = (round your response to four decimal places).arrow_forward

- 54 Boxes of Honey-Nut Oatmeal are produced to contain 14.0 ounces, with a standard deviation of 0.20 ounce. For a sample size of 64, the 3-sigma X chart control limits are: Upper Control Limit (UCL) = ounces (round your response to two decimal places).arrow_forwardThe Road King Tire Company in Birmingham wants to moni-tor the quality of the tires it manufactures. Each day the com-pany quality-control manager takes a sample of 100 tires, tests them, and determines the number of defective tires. The re-sults of 20 samples have been recorded as follows:Construct a p-chart for this process using 2 limits and for each of the last 30 weekdays are shown as follows:describe the variation in the process. Sample Defectives Sample Defectives1 14 11 182 12 12 103 9 13 194 10 14 205 11 15 176 7 16 187 8 17 188 14 18 229 16 19 2410 17 20 23arrow_forward7. An ad agency tracks the complaints, by week received, about the billboards in its city: Week No. of Complaints 1 3 2 6 3 4 4 12 5 2 6 9 This exercise contains only parts a, b, and c. Part 2 a) The type of control chart that is best to monitor this process is c minus chart ______ . Part 3 b) Using z = 3, the control chart limits for this process are (assume that the historical complaints rate is unknown): UCLc = ________ complaints per week (round your response to two decimal places). The upper control limit is: ________ The lower control limit is: _________ The central limit is ___________arrow_forward

- concernedas to whether caulking tubes are being properly capped. Ifa significant proportion of the tubes are not being sealed,Webster is placing its customers in a messy situation.Tubes are packaged in large boxes of 144. Several boxes areinspected, and the following numbers of leaking tubes arefound: Calculate p-chart three-sigma control limits to assesswhether the capping process is in statistical control.arrow_forwardJus de Fruit Co. has set up for automated production of its new bottled Triple Berry Colada. Six samples were taken during the first week of production. The OM team wants to check if the dispersion of the process is in control. What will be the 3-sigma upper and lower control limits, respectively? Sample Bottle 1 Bottle 2 Bottle 3 Bottle 4 1 16.5 16.3 15.7 16.2 2 16.1 16 15.5 16.1 3 16.3 16.5 15.8 15.7 4 15.6 16 16.3 16.2 5 16 15.9 16.2 15.8 6 15.9 16.3 16.1 15.5arrow_forwardLinda Boardman, Inc., an equipment manufacturer in Boston, has submitted a sample cutoff valve to improve your manufacturing process. Your process engineering department has conducted experiments and found that the valve has a mean (u) of 12.00 and a standard deviation (a) of 0.04. Your desired performance is μ = 12.00 +3 standard deviations, where a = 0.045. For the given information, the process capability index (Cpk) - (round your response to three decimal places).arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.