Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

Motiyo

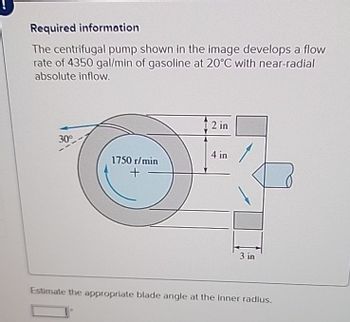

Transcribed Image Text:Required information

The centrifugal pump shown in the image develops a flow

rate of 4350 gal/min of gasoline at 20°C with near-radial

absolute inflow.

1 2 in

30°

4 in

1750 r/min

+

3 in

Estimate the appropriate blade angle at the inner radius.

SAVE

AI-Generated Solution

info

AI-generated content may present inaccurate or offensive content that does not represent bartleby’s views.

Unlock instant AI solutions

Tap the button

to generate a solution

to generate a solution

Click the button to generate

a solution

a solution

Knowledge Booster

Similar questions

- A single stage centrifugal pump has an impeller of 250 mm diameter which rotates at 1,800 rpm and lifts 60 lit/sec to 25 m with an efficiency of 70%. Obtain the number of stages and diameter of each impeller of a similar multi-stage pump to lift 75 lit/sec to 175 m at 1,500 rpm. (8 stages ; 280 mm dia)arrow_forwardAnalyze to select the type of the turbine when its diameter is 600 mm, rotational speed is 600 rpm and working under a water head of 120 meters. The buckets deflect the 100 mm diameter jet through an angle of 165°. Take the coefficient of velocity for the nozzle as 0.97. Use Table given below for selection of turbine. Sr. # Specific speed (rpm) Type of turbine 1 8-30 Pelton wheel with one nozzle 30 - 50 Pelton wheel with 2 or more nozzles 50-250 Francis turbine 4 250-1000 Kaplan turbine 2. 3.arrow_forwardThis course EHide block A centrifugal pump with the following impeller dimensions is used to pump water. The pump is running at 1000 rpm. The ideal head rise through the pump is 190 ft. b2 Poz 72 by The parameters of the impeller are as follows: r2= 9in, b2=3in, B2= 31° Take g= 9.81 m/s23 32.2 ft/s2 pw = 998 kg/m3 = 1.94 Slug/ft. Determine the theoretical flow rate in gpm Choose.. Determine the theoretical Power shaft in (hP) Choose...arrow_forward

- Nonearrow_forwardEX1: Given are the following data for a commercial centrifugal water pump: r1 =10 cm, r2 = 17.5 cm, By =30°, B2 =20°, speed =1440 r/min. Estimate (a) the design point discharge, (b) the water horsepower, and (c) the head if by = b2 = 4.4 cm.(Hint. design point discharge, i.e 11=90°)arrow_forwardProblem 2. Performance data are given in the table below for a centrifugal pump with an impeller diameter of D = 9.0 inches operating at a speed of N = 1750 rpm collected on a pump test stand using water at STP. For this pump test there are no changes in elevation or velocity between the suction inlet and pump discharge. (a) Plot the actual pump head and pump efficiency versus flowrate. (b) Use a curve fit to obtain a pump curve, H₂ = H0 - C₂ Q². (c) Use a curve fit to obtain a 2nd order polynomial fit for the efficiency curve. (d) Calculate the best efficiency point. Q (gpm) 20 40 60 80 100 120 140 Ap (psi) 40.2 40.1 38.1 36.2 33.5 30.1 25.8 Wm (hp) 1.58 2.27 2.67 2.95 3.19 3.49 4.00arrow_forward

- EX1: Given are the following data for a commercial centrifugal water pump: r1 =10 cm, rz = 17.5 em, B1 =30°, B2 =20°, speed =1440 r/min. Estimate (a) the design point discharge, (b) the water horsepower, and (c) the head if bs = bz = 4.4 cm.(Hint. design point discharge, i.e €:=90°)arrow_forward1 The internal and external diameters of the impeller of a centrifugal pump are 200 mm and 400 mm respectively. The pump is running at 1200 rpm. Forward blades make an angle of 150o at exit and at inlet the angle is 20o. The blade thicknesses at the inlet and outlet are 100mm and 70mm respectively. The hydraulic efficiency of the pump is 87%. Assume the water enters the impeller radially. i Draw neatly the outlet velocity diagram and the inlet velocity diagram. ii Find the Euler power of the pump. iii Find the net Head of the pump. Ans: (ii)140.65W; (iii) 43.42marrow_forwardDisplacement (c): 0.2 in3/revShank diameter (d) = 0.625 in.Piston diameter (D) = 1.5 in.Rotation speed (n): 1725 RPMPressure (P): 600 PSIStroke (L) = 18in. a) Calculate the theoretical flow rate of the pump in in3/min and US GPM.Theoretical flow (Q) = Theoretical displacement (C) x Speed of revolution (n)Theoretical flow (Q) = 0.2 in3/rev x 1725 rpmTheoretical flow (Q) = 345 in3/min = 1.49 US GPM b) Calculate the cylinder output speed in in/s.Cylinder output speed (VS) = Piston side flow (Q) / Piston area (Ap)Cylinder output speed (VS) = (Displacement x Speed of revolution) / Piston area (Ap)Cylinder output speed (VS) = (0.2 in3/rev x 1725 RPM) / 1.77 in2Cylinder output speed (VS) = (0.2 in3/rev x 1725 RPM) / 1.77 in2Cylinder output speed (VS) = 196.02in/s = 196.02 / 60s = 3.20 in/s Questions: c) Knowing the output velocity (ram speed), calculate the rod side flow in GPM when the ram is extending. d) Calculate the piston exit time in seconds. e) Calculate the piston entry time in…arrow_forward

- A centrifugal pump impeller has an external diameter of 1.2 m and internal diameter of 0.8 m. The width of the impeller at outlet is 0.175 m and the blade angle at outlet is 65 degrees. The flow velocities at inlet and outlet are the same (Va1 = Va2). This pump delivers 1.55 m3/s of water at 210 rpm. For theoretical performance, calculate: 1-The flow velocity . 2-blade speed at outlet. 3-blade angle at inlet (in degrees). 4-the developed head. 5-The pressure rise across the impeller. 6-The number of blades . 7-The NPSH . %3Darrow_forwardThe three-lobe (on each rotar) rotary pump moves 0.145 gal of a coal slurry in each lobe volume Vlobe = 0.103 gal. Calculate the volume flow rate of the slurry (in gpm) for the case where n. = 220 rpm.arrow_forwardRefer to the “composite performance chart” for a Goulds 3x4-10centrifugal pump operating at 1750 rpm. It shows the pump performance curve for 5 differentimpeller sizes, but also shows the HP required, efficiency, and NPSH required at differentoperating points.Describe the performance of this pump, using an 8 inch impeller and a required flow rate of175 gpm. Give head available, power required (BHP), efficiency, and NPSH req’d. What is the water horsepower (WHP)?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY