Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

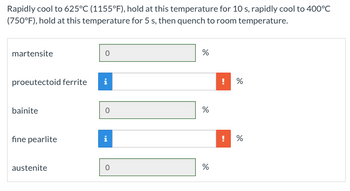

Transcribed Image Text:Rapidly cool to 625°C (1155°F), hold at this temperature for 10 s, rapidly cool to 400°C

(750°F), hold at this temperature for 5 s, then quench to room temperature.

martensite

proeutectoid ferrite i

bainite

fine pearlite

austenite

%

%

%

! %

do

%

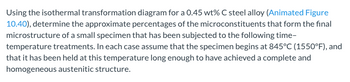

Transcribed Image Text:Using the isothermal transformation diagram for a 0.45 wt% C steel alloy (Animated Figure

10.40), determine the approximate percentages of the microconstituents that form the final

microstructure of a small specimen that has been subjected to the following time-

temperature treatments. In each case assume that the specimen begins at 845°C (1550°F), and

that it has been held at this temperature long enough to have achieved a complete and

homogeneous austenitic structure.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 7. Consider 1.5 kg of a 99.6 wt% Fe-0.4 wt% C steel that is cooled to a temperature just below the eutectoid. (a) How many kilograms of ferrite (a) form? (b) How many kilograms of cementite (Fe;C) form? Include your tie line in the solution. 1600| L 1400 T(°C) 1200 (austenite) y+L 1148°C L+Fe;C 1000 Y + Fe;C 800 727°C 600 a + Fe;C 400 1 2 4 6 6.7 C, wt% C Fe;C (cementite)arrow_forwardUse the phase diagrams for Cu-Ni and Cu-Ag systems below to answer the question: Based on the mechanism, would you expect a solution containing 80 wt% Cu to be stronger if the remaining 20% of the alloy was Ni or Ag? Briefly explainarrow_forward1. four processes. 2. Fill out the blanks by labeling the phase regions. 3. Identify the Indicate an in- termediate compound, if any. 3. Temperature (°C) 1600 1400 1200 1000 800 600 400 1538°C 0 (Fe) -1493°C 1394°C 912°C y, Austenite 1 2 0.16 5 0,022 a, Ferrite A N 2.14 Composition (at% C) 15 10 3 1147°C L4 3 4 Composition (wt% C) 4.30 727°C Sketch the microstructure at A, label phases, figure out compositions. 20 Cementite (Fe3C). 5 6 25 6.70arrow_forward

- Use the Lead-Tin (Pb-Sn) phase diagram below to answer the following questions: Place the following microstructures in the correct order of formation for slowly cooling a 98 wt% Sn alloy from 300 °C to room temperature (point A to point B).arrow_forwardiii) For a 68 wt% Zn-32 wt% Cu alloy, make schematic sketches of the microstructure that would be observed for conditions of very slow cooling at the following temperatures: 1000°C, 760°C, 600°C and 400°C. Label all phases and indicate their approximate compositions. Comportion a In 20 40 60 100 1200 |2200 H2000 Liquid 1000 - 1800 デ+ダ H1600 J400 E 1200 600 400 『+キ 600 200 400 40 60 Conpositon tet% Zroarrow_forwardAccording to the following graph, two samples of 1080 steel are cooled from the eutectoid temperature, one at a cooling rate of 250°C/s and the other at a cooling rate of 7.27x10-8 °C/s. Specify the phases obtained and explain their formation from thermodynamic and kinetic perspectives. Also, briefly describe their formation. Draw the microstructure of the phases obtained. Sıcaklık (C) 800 700 600 500 400 300 200 100 0 10 1 T M(başlama) M(% 50) M(% 90) 10 M+O -Otektoid Sıcaklık 10² Zaman (s) % 50 10³ 104 105arrow_forward

- A 50 wt% Pb-50 wt% Mg alloy is slowly cooled from 700 °C (1290 °F) to 400 °C (750 °F). (a) At what temperature does the first solid phase form? (b) What is the composition of this solid phase? (c) At what temperature does the liquid solidify? (d) What is the composition of this last remaining liquid phase? Temperature (°C) 700 600 500 400 300 200 100 2 0 0 (Mg) 560°C First solid (21 wt% Pb) α 20 465°C 5 a + L Composition (at% Pb) 40 10 L a + Mg₂Pb 20 60 Composition (wt% Pb) Last liquid (67 wt% Pb) 30 Mg₂Pb 40 T T L + Mg₂Pb M 18 80 L + Mg₂Pb 70 100 B B+ Mg₂Pb T B + L D T 1200 1000 800 600 400 200 100 (Pb) Temperature (°F)arrow_forwardrams A copper-nickel alloy of composition 75 wt% Ni-25 wt% Cu is slowly heated from a temperature of 1300°C (1573). (a) At what temperature does the first liquid phase form? (b) What is the composition of this liquid phase? T(°C) 1600 (c) At what temperature does complete melting of the alloy occur? (d) What is the composition of the last solid remaining prior to complete melting? 1500 1400 1300 1200 1100 1000 17 / 17 0 L (liquid) 20 liquidus + a solidus 100% 40 α (FCC solid solution) 60 80 100 wt% Ni 17arrow_forwardConsider the phase diagram below. The three points A, B, and C are at concentrations of 26.4, 31.3, and 34 wt% Ni respectively. The ends of the tie line are at C1 = 25% wt% Ni and C2 = 35 wt% Ni. What are the weight fractions of the alpha phase at A and the L phase at B, as well as the alpha phase/L phase ratio at C? T(°C) 1300 L (liquid) 1200 20 A B C L + a C1 S liquidus L + a solidus a (solid) 50 wt% Ni a. Walpha=0.21; WL=0.33; Walpha/WL = 13.17 b. Walpha=0.09; WL=0.32; Walpha/WL = 15.00 c. Walpha=0.07; WL=0.46; Walpha/WL = 11.17 d. Walpha=0.14; WL=0.37; Walpha/WL = 9.00arrow_forward

- Is it possible to have a copper-nickel alloy that, at equilibrium, consists of a liquid phase of composition 20 wt% Ni-80 wt% Cu and also an a phase of composition 37 wt% Ni-63 wt% Cu? If so, what will be the approximate temperature of the alloy? If this is not possible, explain why. Temperature (°C) 1600 1500 1400 1300 1200 1100 1000 0 1085°C (Cu) 20 Liquid Liquidus line L B 40 a+L a A 60 Composition (wt% Ni) (a) 1455°C Solidus line 80 2800 2600 2400 2200 2000 100 (Ni) Temperature (°F) Temperature (°C) 1300 1200 20 Liquid Tie line. a + Liquid a 1 KR I 1 1 B ↑ Co a + Liquid -S 30 CL Composition (wt% Ni) (b) 40 1 Ca a 50arrow_forwardthis is material science questionarrow_forwardMaterial science Assuming this system forms a laminar type eutectic, determine the volume proportion of phases for an equilibrium solidified 50% Pb alloy. Sketch the expected microstructure.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY