Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

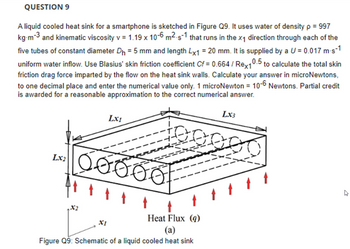

Transcribed Image Text:QUESTION 9

A liquid cooled heat sink for a smartphone is sketched in Figure Q9. It uses water of density p = 997

kg m-3 and kinematic viscosity v = 1.19 x 10-6 m²-s-1 that runs in the x₁ direction through each of the

five tubes of constant diameter D₁ = 5 mm and length Lx1 = 20 mm. It is supplied by a U = 0.017 m-s-1

uniform water inflow. Use Blasius' skin friction coefficient Cf = 0.664 / Rex1

0.5 to calculate the total skin

friction drag force imparted by the flow on the heat sink walls. Calculate your answer in microNewtons,

to one decimal place and enter the numerical value only. 1 microNewton = 10-6 Newtons. Partial credit

is awarded for a reasonable approximation to the correct numerical answer.

Lx₂

X2

Lx1

X1

Ő ve

Heat Flux (9)

(a)

Figure Q9: Schematic of a liquid cooled heat sink

LX3

4

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Problem 6-1: The Reynolds number is an engineering parameter that relates to the volume flow rate of a fluid 4Q where vis πνd m² through a tube of diameter d as Red the fluid kinematic viscosity. Determine the Reynolds number and its uncertainty by general analysis given d = 50.4 ±0.1 mm, Q = 0.213 +0.005 S v = 0.999 × 10-6 ± 0.005 × 10-6 m². Which variable contributes the most to the overall uncertainty? Assume uncertainties are at 95 % confidence. Sarrow_forwardProblem 2 The apparatus sketched in the figure below serves as a viscometer i.e. it can be used to measure the viscosity of a liquid. In the drawing, D is a large reservoir containing a viscous liquid A and E is a cylindrical tube of radius R, open at both ends, surrounding and coaxial with B, which is a cylindrical "bob" of radius êR that is dragged up through the fluid by a frictionless pulley system (C) utilizing a weight W. Determine a design equation that relates the viscosity of the liquid to the geometry of the system and the weight W. Hint: you can assume that the length of the cylindrical tube is sufficiently long for the flow to reach steady state. W E D Barrow_forwardPlease help me question 2.6arrow_forward

- Working for an engineering consultancy firm, your knowledge of fluid dynamics is required to design a new safety feature for a high-pressure air line in a factory. The air line takes the form of a cylindrical pipe of diameter 150 mm, which is designed to operate between 0.45 MPa and 0.76 MPa. At the end of the pipe a burs9ng disk is placed so that, if the pressure exceeds the maximum opera9ng pressure, the air is vented to atmosphere rather than over-pressuring the chemical reac9on vessel (Figures 4a and 4b). In this ques9on, you should treat the flow as quasione-dimensional and inviscid. The air in the surrounding atmosphere is at 101 kPa and 298 K. a) You have a choice of five disks which can withstand the following forces across them before burs9ng: 10.5 kN, 11.0 kN, 11.5 kN, 12.0 kN, 12.5 kN. Which of these burs9ng disks would you recommend, and why? b) Due to an over-pressurisa9on of the air line, the disk bursts at 9me t = 0. At what pressure in the air line will this occur? c)…arrow_forwardPlease help, will give helpful ratings if correct!!!arrow_forwardCorection the following number k=.02625,Kinematic viscosity(fancy v)=16.55*10^-6m^2/s,Pr=.7 Re(x=L)=54380 Nu(x)=170.1 h(x=L)=29.8 Ts(l)=54.9Carrow_forward

- Example(1-13): steam and water flow through 75 mm inside diameter pipe at flow rate of 0.05 and 1.5 m³/s respectivily. If the mean temperature and pressure are 330 K and 120 kpa, what is the pressure drop per unit length of pipe. Where the pipe roughness 0.00015 mm, liquid and gas viscosities are 0.52x10³ pa.s and 0.0133x10-³ pa.s.arrow_forwardProblem 2 For this problem, use the graph below, also given at the end of the notes on stress concentration. Determine the stress concentration factor in a 0.2 inch thick flat bar with two symmetric grooves (semi-circular notches) of radius 0.3 inches and width 2.6 inches. Use the graph in Fig. 2. 3.0 Nolched rectangular bar in lension or simple compression. a0 = F/A, where A = dt and is the thickness. 2.6 2.2 1.2 K, 1.1 1.8 1,05 14 1.0 0,05 0.10 0.15 0.20 0.25 0.30 rld Fig. 2arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY