FINANCIAL ACCOUNTING

10th Edition

ISBN: 9781259964947

Author: Libby

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Question

A1

Transcribed Image Text:Question 6 of 7

<

>

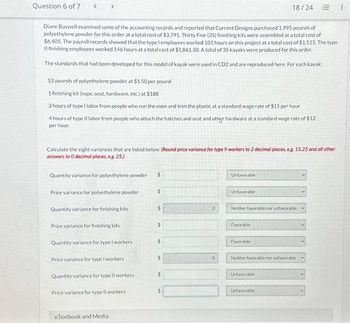

Diane Buswell examined some of the accounting records and reported that Current Designs purchased 1,995 pounds of

polyethylene powder for this order at a total cost of $3,791. Thirty Five (35) finishing kits were assembled at a total cost of

$6.405. The payroll records showed that the type I employees worked 101 hours on this project at a total cost of $1,515. The type

Il finishing employees worked 146 hours at a total cost of $1,861.50. A total of 35 kayaks were produced for this order.

The standards that had been developed for this model of kayak were used in CD2 and are reproduced here. For each kayak:

53 pounds of polyethylene powder at $1.50 per pound

1 finishing kit (rope, seat, hardware, etc.) at $188

3 hours of type I labor from people who run the oven and trim the plastic at a standard wage rate of $15 per hour

4 hours of type Il labor from people who attach the hatches and seat and other hardware at a standard wage rate of $12

per hour.

Calculate the eight variances that are listed below. (Round price variance for type II workers to 2 decimal places, e.g. 15.25 and all other

answers to O decimal places, e.g. 25.)

Quantity variance for polyethylene powder $

Price variance for polyethylene powder

Quantity variance for finishing kits

Price variance for finishing kits

Quantity variance for type I workers

Price variance for type I workers

Quantity variance for type ll workers

Price variance for type Il workers

eTextbook and Media

$

$

0

0

Unfavorable

Unfavorable

18/24 E

Neither favorable nor unfavorable v

Favorable

Favorable

Neither favorable nor unfavorable

Unfavorable

Unfavorable

***

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 10 images

Knowledge Booster

Similar questions

- What information is included in Form 10-K?arrow_forwardHansen Corporation. a C Corporation (mot a manufacturer) reports the following items in income and expenses for 2021 Gross Revenue $900,000 Dividend Received from 30% owned Corp 200,000 LTCG 30,000 STCL 12000 City of Lee's Summit Bond Interest 10000 COGS 375000 Administrative Expenses 325000 Charitable Contribution 60,000 Compute Hansen's C Corp Taxable income?arrow_forwardProblem 20-96 from pic.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning,

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning, Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON

Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education

Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Accounting

Accounting

ISBN:9781337272094

Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.

Publisher:Cengage Learning,

Accounting Information Systems

Accounting

ISBN:9781337619202

Author:Hall, James A.

Publisher:Cengage Learning,

Horngren's Cost Accounting: A Managerial Emphasis...

Accounting

ISBN:9780134475585

Author:Srikant M. Datar, Madhav V. Rajan

Publisher:PEARSON

Intermediate Accounting

Accounting

ISBN:9781259722660

Author:J. David Spiceland, Mark W. Nelson, Wayne M Thomas

Publisher:McGraw-Hill Education

Financial and Managerial Accounting

Accounting

ISBN:9781259726705

Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting Principles

Publisher:McGraw-Hill Education