Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

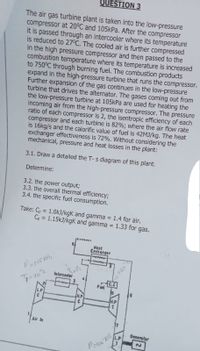

Transcribed Image Text:QUESTION 3

The air gas turbine plant is taken into the low-pressure

compressor at 20°C and 105kPa. After the compressor

it is passed through an intercooler where its temperature

is reduced to 27°C. The cooled air is further compressed

in the high pressure compressor and then passed to the

combustion temperature where its temperature is increased

to 750°C through burning fuel. The combustion products

expand in the high-pressure turbine that runs the compressor.

Further expansion of the gas continues in the low-pressure

turbine that drives the alternator. The gases coming out from

the low-pressure turbine at 105kPa are used for heating the

incoming air from the high-pressure compressor. The pressure

ratio of each compressor is 2, the isentropic efficiency of each

compressor and each turbine is 82%; where the air flow rate

is 16kg/s and the calorific value of fuel is 42MJ/kg. The heat

exchanger effectiveness is 72%. Without considering the

mechanical, pressure and heat losses in the plant:

3.1. Draw a detailed the T- s diagram of this plant.

Determine:

3.2. the power output;

3.3. the overall thermal efficiency;

3.4. the specific fuel consumption.

Take: Cp = 1.0kJ/kgK and gamma

Cp = 1.15kJ/kgK and gamma = 1.33 for gas.

1.4 for air.

%3D

Heat

Exchanger

Interceoler

7=20°

C.C

Fuel

16

L.P

H.P

H.P

Air in

Generalor

L.P

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Hi, can you only help with part a of the following?arrow_forwardQuestion 3 Consider the turbocharger of an internal combustion engine. The exhaust gases enter the turbine at 450°C at a rate of 0.02 kg/s and leave at 400°C. Air enters the compressor at70°C and 95 kPa at a rate of 0.018 kg/s and leaves at 135 kPa. The mechanical efficiency between the turbine and the compressor is 95 percent (5 percent of turbine work is lost duringits transmission to the compressor). Using air properties for the exhaust gases, determine:(a).The turbine power output, compressor power input, air temperature at the compressor exit,(b).The air temperature at the compressor for the case of isentropic process and isentropic efficiency of the compressor.arrow_forwardBiomass is used as fuel to power the following cogeneration plant on a school. The turbine drives an electric generator to produce electricity, and part of the steam is extracted to provide heating to campus buildings. The boiler provides 106 kg/h of steam at 6 MPa, 520 °C, of which 4x105 kg/h is extracted between the first and second turbine stages at 1 MPa and diverted to the building heating load. Condensate returns from the building heating load at 0.95 MPa, 115 °C, and it is mixed with liquid exiting the lower pressure pump at 0.95 MPa. The entire flow is then pumped to the boiler pressure. Saturated liquid at 6 kPa leaves the condenser. The turbine stages and the pumps operate with isentropic efficiencies of 89 and 85%, respectively. The efficiency of the electric generator is 93% for converting turbine mechanical power into electricity. Calculate the heating load in kJ/h. Calculate the electric power generated in MWe.arrow_forward

- first 2 parts pleasearrow_forwardA boiler furnace releases 10 400 kj of heat for each kg of fuel burned and produces dry staturated steam at 14000 kpa from feedwater at 200 degrees celcius . How many kg of steam will be produced for each kg of fuel burned if the boiler had an efficiency of 66% ? .arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY