Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:<>

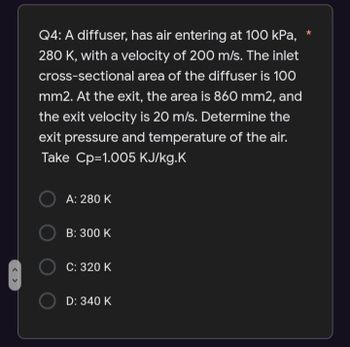

Q4: A diffuser, has air entering at 100 kPa,

280 K, with a velocity of 200 m/s. The inlet

cross-sectional area of the diffuser is 100

mm2. At the exit, the area is 860 mm2, and

the exit velocity is 20 m/s. Determine the

exit pressure and temperature of the air.

Take Cp=1.005 KJ/kg.K

OA: 280 K

OB: 300 K

OC: 320 K

D: 340 K

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 100% High pressure water and compressed air are delivered to some operating rooms. Bored one day, with no patients around, you take the cap off the nozzle to see what would happen. Water flows through the vertical pipe and nozzle and then exhausts into the air as shown in the diagram. The water pressure in the pipe at position 1 is 3 atm. The pressure when the water discharges to the air is 1 atm. Position 2 identifies the nozzle, 0.75 m above position 1, where the water flow has been constricted from an 8-cm diameter pipe to a 3-cm diameter nozzle. Assume that the free jet remains a stream of water with a 3-cm diameter. Assume no friction losses. Free jet -3 cm diameter 0.75 m a) Determine the mass flow rate of water through pipe at position 1 in kg/s. 3 atm 8 cm diameter b) Determine the height, h, the water jet can rise. c) Calculate the friction factor inside the 8-cm pipe and determine if the assumptions of negligible friction losses was reasonable. Water AR d 128 PM 10/3/2021…arrow_forwardQ4. Water from a reservoir is conveyed via a pipeline of constant diameter and 1000m length to a turbine situated 90m below the reservoir surface level. The velocity of flow through the pipeline is 5m/s and the energy loss due to friction in the pipeline is 200J/kg. The water leaves the turbine at atmospheric pressure (100 kN/m2) and with negligible velocity. Assuming an efficiency of 85% for the turbine, determine: a). Pipeline diameter b). Pressure at entry to turbine c). Turbine power output. Take f = 0.025arrow_forwardHi please help me answer this question with complete solutionarrow_forward

- Air enters a turbine at temperature and pressure of 800°C, 10bar respectively. The actual exit airtemperature is 180°C. The turbine isentropic efficiency is estimated to be 85%. Calculate the turbine exit pressure and the actual expansion index (n).arrow_forwardProblem (6.1) Steam at 1.8 MPa and 275 °C expands through a convergent- divergent nozzle to 0.1 MPa. If there is 10 % loss in energy between the throat and the nozzle exit and the vapor flow rate is 0.5 kg/s, determine the cross- sectional area of the throat and the nozzle exit.arrow_forward2. An ideal gas, following the relationship (Pv = 75 m2/s²), flows in a horizontal pipe at a constant temperature. The internal diameter of the pipe is 0.025 m and the pressure drop is 11 kPa for each 5m length. Calculate the mass flow rate per unit area in kg/sm2, assuming the pressure at the end of the pipe is 12 kpa and the friction factor f = 0.009. Ignore the kinetic energy.arrow_forward

- A steady stream of n-butanol is needed to be fed into the reactor at 40 ̊C. However, the inlet of the reactor is located 7.5 m above the reservoir tank. As such, a highly effective centrifugal pump (70% efficiency) is used for such a purpose. It was understood that the needed volumetric flow rate into the reactor is fixed at 20 m3/h. It was also noted that the n-butanol reservoir is closed but not pressurized, while the gauge pressure at the endof the discharge line is measured at 275 kPa. Given that the density of n-butanol is 810kg/m3. If the discharge pipeline was 5 cm in diameter, calculate: (i) The velocity of n-butanol at the discharge line. (ii) The total power input from the centrifugal pump. (iii) The power delivered to the n-butanol fluid.arrow_forwardChoose the following and define alsoarrow_forwardThe power output of a steam turbine is 5 MW. The inlet conditions are 2 MPa of pressure, 400 degrees * C of temperature, 50 m/s of velocity and 10 m of elevation. The exit conditions are 15 kPa, 0.9 dry quality, 180 m/s and 6 m elevation. Compute: (i) The magnitude of A h, A ke, Ape, (ii) Work done per kg of steam,arrow_forward

- 2. Two gaseous streams enter a combined tube in a steady flow manner and leave as a single mixture Gas A at Tube A Gas B at Tube B A= 400 cm? V= 150 m/s V=0.6 m³/kg A= 250 cm? m= 455kg/min p= 2kg/m³. Data at exit: V= 100 m/s v=0.55 m/kg Find the following: a. Speed of gas at tube B b. Mass flow rate at exitparrow_forwardSolve it correctly please. I will rate accordingly.arrow_forwardAn ideal gas passes a diffuser. At the diffuser inlet, the temperature is T1 = 350.00 K, the pressure P1 = 100.00 kPa, the velocity V1 = 200.00 m/s, and the inlet area A1 = 0.30 m2. At the exit, the velocity is very small. The specific heat of the ideal gas at the constant pressure is cp = 1.0050 kJ/(kg·K). The gas constant is R = 0.2870 kPa·m3/(kg·K). Determine the enthalpy per unit mass at the exit, h2__________(kJ/kg)arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY