Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

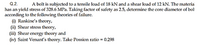

Transcribed Image Text:Q.2.

A bolt is subjected to a tensile load of 18 kN and a shear load of 12 kN. The materia

has an yield stress of 328.6 MPa. Taking factor of safety as 2.5, determine the core diameter of bol

according to the following theories of failure.

(i) Rankine's theory,

(ii) Shear stress theory,

(iii) Shear

(iv) Saint Venant's theory. Take Possion ratio = 0.298

energy theory and

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A brittle material has the properties . Sut = 30 kpsi and Suc = 90 kpsi Using the brittle Coulomb-Mohr and modified-Mohr theories, determine the factor of safety for the following states of plane stress.arrow_forwardThe shaft is supported by journal bearings at A and B that exert force components only in the x and z directions. Part A d= PLÅ Value Ĵ t O Determine the smallest diameter of the shaft. Use the maximum shear stress theory of failure with Tallow Express your answer to three significant figures and include appropriate units. Units HATT F = 200 lb ? X 8 in. 1 4 in. 8 in. N A 8 ksi 4 in. D F. = 50 lb 8 in. 4 in. F = 250 lb 4 in. SE B yarrow_forwardQ1) A ductile hot-rolled steel bar has a minimum yield strength in tension and compression of Syt = 50 kpsi and Sye = 65 kpsi. Using the ductile Coulomb-Mohr theory, determine the factor of safety for the states of plane stress. 0x = 35 kpsi, and oy = 20 kpsi, Txy бу 0 Submit your answer in 4 significant digits. =arrow_forward

- Required information A ductile hot-rolled steel bar has a minimum yield strength in tension and compression of 350 MPa. Using the distortion- energy and maximum-shear-stress theories, determine the factors of safety for the following plane stress states. 0x² =104 MPa, 0y = 19 MPa, and Txy = -19 MPa I The factor of safety from the maximum-shear-stress theory is 3.8 3.45 and the factor of safety from the distortion-energy theory isarrow_forwardProblem 19.1 The shaft shown in the following diagram is supported by two self-aligning bearings at A and B and is subjected to the loads shown on the chain sprockets. 50 mm 100 mm. 100 mm F 30 mm 3000 N 100 mm 50 mmarrow_forwardTwo steel plates are held together by two bolts. (/6) a. Determine the required diameter of the bolts if the failure shear stress is 300 MPa using a Factor of Safety (FS) of 2. b. Using the answer from a. above, determine the steel plate thickness if the failure bearing stress of the steel is 350 MPa using FS = 1.5. Show your work. OKN Two Bolts P=60KNarrow_forward

- please helparrow_forward5. A brittle steel bar has the dimensions shown. Determine the maximum axial force P that can be applied not to exceed the allowable tensile stress of allow= 100 MPa. (Make sure to determine and account for the stress concentration factors). K 3.0 2.8 2.6 2.4 2.2 2.0 1.8 1.6 1.4 1.2 1.0 0 P 0.1 0.2 0.3 W h W h 30 mm - 4.0 = 3.0 W Jang W h W h II = || 24 mm it P ht 2.0- = 1.5. T AL W W 12 mm 1.2- - 0.4 0.5 0.6 0.7 0.8 0.9 r 1.0 K 60 mm 3.2 3.0 2.8 2.6 2.4 2.2 2.0 0 0.1 r = 15 mm P 0.2 2r avg 0.3 2r P (w – 2r)t 0.4 0.5arrow_forwardWhy does the answer of this problem consider radial stress if it is a thin walled?arrow_forward

- The principal stresses at a point in a critical section of a machine component are sigma_{1} = 60MPa, sigma_{2} = 5MPa and sigma_{3} = - 40MPa For the material of the component, the tensile yield strength is sigma_{y} = 200 MPa According to the maximum shear stress theory,what is the factor of safety.arrow_forwardPlease provide the correct solution asap. Handwritten recommendedarrow_forwardThe material for the bolt shown in Figure 2, the angled joint has an ultimate tensile strength of 600 MPa and shear strength of 300 MPa. The diameter of the bolt is 10 mm. Determine the factor of safety. Assume force of F = 25 kN. F+ 60% Figure. 2 Farrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY