Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

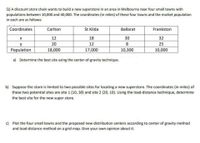

Transcribed Image Text:Q) A discount store chain wants to build a new superstore in an area in Melbourne near four small towns with

populations between 10,000 and 40,000. The coordinates (in miles) of these four towns and the market population

in each are as follows:

Coordinates

Carlton

St Kilda

Ballarat

Frankston

12

18

30

32

20

12

8

25

Population

18,000

17,000

10,300

10,000

a) Determine the best site using the center-of-gravity technique.

b) Suppose the store is limited to two possible sites for locating a new superstore. The coordinates (in miles) of

these two potential sites are site 1 (10, 30) and site 2 (20, 10). Using the load-distance technique, determine

the best site for the new super store.

c) Plot the four small towns and the proposed new distribution centers according to center of gravity method

and load-distance method on a grid map. Give your own opinion about it.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 4 images

Knowledge Booster

Similar questions

- William Green, vice president of manufacturing for computer products (CPC), and his staff are studying three midwestern alternative locations for a new production facility for producing high-resolution scanners. His staff analysts predict that the scanners will be a growing market over the next ten years, and the analyst's group shares marketing's enthusiasm for planning facilities for producing this new product line. The analysts have developed these estimates for the three locations; In what range of production volume would each of the locations be preferred (at the minimum cost)? Variable cost locations Annual Fixed costs per scanner Cleveland, Ohio $390,000 $34 South Bend, Indiana $360,000 $37 Grand Rapids, Michigan $310,000 $40arrow_forwardThe university administration would like to add some additional parking locations. To make everyone happy, they would like each building to be within a 5 minute walk of one set of new parking spaces (the spaces will be added in blocks of 10 parking spaces). The university is considering six locations for the new parking spaces, but would like to minimize the overall cost of the project. In addition to the walking time requirement, the university would like to add at least 40 new parking spaces (at least 4 blocks of 10). To help with the decision, the management science department formulated the following linear programming model: Min 350x1 + 425x2 + 425x3+ 465x4 + 485x5 + 365x6 s.t. x1 + x2 + x5 + X6 2 1 (Residence Hall A constraint) x1 + x2 + X3 2 1 {Residence Hall B constraint) X4 + X5 + X6 2 1(Science building constraint) X1 + X4 + X5 2 1{Music building constraint} x2 + x3 + X4 2 1{Math building constraint} x3 + X4 + X5 2 1{Business building constraint} x2 + x5 + X6 2 1{Auditorium…arrow_forward1. Using the center-of-gravity method, compute the centralized coordinates among the following locations, which are indicated via black cells with white text in LOCATION.xlsx: 7,1 10,1 4,2 2,5 6,6 9,6 2,8 6,10 2. Using the weighted average center-of-gravity, which accounts for quantities to be shipped from locations, compute the centralized coordinates among the following locations: 7,1 10,1 4,2 2,5 6,6 9,6 2,8 6,10 *Quantities to be shipped are listed within the existing locations (i.e. Location 7,1 ships 17 units) in LOCATION.xlsxarrow_forward

- Eagle Electronics must expand by building a second facility. The search has been narrowed down to locating the new facility in one of four cities: Atla nta (A),Baltimore (B), Chicago (C), or Dallas (D). The factors, scores,and weights follow: a) Using the factor-rating method, what is the recommended site for Eagle Electronics's new facility?b) For what range of values for the weight (currently w7 = I 0) does the site given as the answer to part (a) remain a recommended site?arrow_forward~m8h5q2~arrow_forwardProblem 15-10 (Algo) A small manufacturing facility is being planned that will feed parts to three heavy manufacturing facilities. The locations of the current plants with their coordinates and volume requirements are given in the following table: PLANT LOCATION Peoria Decatur Joliet COORDINATES (x, y) 306, 307 373, 468 468, 175 Cx Cy VOLUME (PARTS PER YEAR) 4,200 6,150 2,900 Use the centroid method to determine the best location for this new facility. (Round your answers to 1 decimal place.)arrow_forward

- In which of the following site selection techniques, a weightage between ‘0’ to ‘1’ is provided to factors that influence its location decision?(a) Location rating factor technique(b) Transportation technique(c) Centre-of-gravity technique(d) None of thesearrow_forward3. A company desires to locate a new facility. Based on preliminary analysis, the choice has been reduced to four locations: A, B, C, and D. These four locations were rated on a scale from 1 worst to 10 best on each of four criteria. Each criterion was also weighted to indicate its importance (i.e., the higher the weight, the more important). The list of ratings and weights follows. Location Weight A Factor Wages Labor climate B 0.40 7 3 5 0.35 9. Local regulation Weather 0.15 4 3 2 0.10 2 8 a- What would be the best location b- If the wights of weather and regulation be divided that the weather would be double of the regulations, what would be the best location LOarrow_forwardA food manufacturer wants to locate a warehouse to serve its major customers. The customers, annual volume and the X and Y coordinates are shown in the table below. Customer Annual Volume X Coordinate Y Coordinate Judy Inc 25 3 7 Zac Supermarket 13 5 2 Harry Inc 6 8 4 Sky Productions 4 1 5 Using the centre of gravity location technique, determine the location coordinates that will minimize the transportation costs for their family of products.arrow_forward

- b. An operations manager has narrowed down the search for a new King Kola plant to three locations. Fixed and variable costs follow. Location Fixed Cost Variable Cost A $100,000 $10 B $150,000 $7 C $200,000 $5 600 Annual 500 Cost ($000) 400 300 200 100 6 8 10 14 16 18 20 0 (000s of units) i. Plot the total cost curves in the chart provided above and identify the range over which each location would be best. ii. Use break-even analysis to calculate exactly the break-even quantity that defines each range.arrow_forwardThe fixed and variable costs for three potential manufacturing plant sites for a rattan chair weaver are shown: a) Over what range of production is each location optimal?b) For a production of 200 units, which site is best?arrow_forwardXun Xu Health and Fitness has several productionfacilities scattered around the central and northern pa rt ofIowa. It would be desirable to have a distribution center fromwhich to send product to retailers such as Sears, WaiMart,Kmart, and large sporting equipment re tailers. Using the datain the following table, calculate the center of gravity locationfor the proposed new facility.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.