Adelie Enterprises is exploring a new service to provide

weekly delivery of grocery items to homes in the greater

Greenwood area. The company’s customers place Web-based

orders and Adelie’s team assembles and delivers the orders in

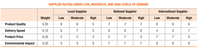

specially designed cardboard boxes. Management, interested

in locating a supplier that can provide boxes cheaply and efficiently, has discovered that each potential supplier’s abil-

ity to satisfy the company’s requirements is influenced by the

level of demand. The following table provides Adelie’s ven-

dor selection criteria, criterion weights, and rankings (1–10

with 10 being the highest) under the assumption that low,

moderate, or high demand is generated for their service.

a. Which supplier should be selected if there is low demand

for Adelie’s new service? Which supplier should be

selected under moderate demand assumptions? Under

high demand assumptions?

b. Which supplier is selected if Adelie evaluates each

alternative using a Maximin decision criterion (see

Supplement A, “Decision Making”)?

c. Which supplier achieves the highest expected ranking

if the probability of low demand is 35 percent, moderate demand is 45 percent, and high demand is

20 percent?

Step by stepSolved in 5 steps with 11 images

- The electronics industry has often come under scrutiny due to:a.) Primarily high pricesb.) Limited supplyc.) Aggravated demandd.) Planning streams of new productsarrow_forwardCustomer – Supplier Relationships of tim hortons based on crmarrow_forward3. Suppose that a logistics company is designing its offering for a manufacturer of frozen foods to deliver their products to various retailers. Assume that the logistics company follows differentiation strategy to gain competitive advantage. How would this logistics company design the following aspects of the offering in order to create value for the frozen food manufacturer? (a) Product (b) Service (c) Delivery (d) Advicearrow_forward

- Consider a three-firm supply chain consisting of a retailer, manufacturer, and supplier. The retailer's demand over an 8-week period was 110 units each of the first 2 weeks, 220 units each of the second 2 weeks, 280 units each of the third 2 weeks, and 400 units each of the fourth 2 weeks. The following table presents the orders placed by each firm in the supply chain. Notice, as is often the case in supply chains due to economies of scale, that total units are the same in each case, but firms further up the supply chain (away from the retailer) place larger, lessfrequent, orders. Week Retailer Manufacturer Supplier 1 110 220 660 2 110 3 220 440 4 220 5 280 560 1360 6 280 7 400 800 8…arrow_forwardPlease provide long detailed answers…… OPMFORMULA is a medium-sized baby formula production plant in Boston, Massachusetts. The company has been in business for over 20 years, mainly producing baby formula for infant nutrition industry and selling the formula exclusively through its distribution network across the United States. Over the years, OPMFORMULA gradually expanded its production capacity and consumer base. However, over the past 24 months, the company has been faced with an unprecedented and unanticipated increase in demand, which has cleared out its storage facilities and exceeded its production capabilities. At this time, the demand continues to be extremely high. The company has an existing storage facility, specifically designed for long-term storage of baby formula (controlled climate, humidity, etc.), which can be converted to a new production line. The new production line would increase the existing manufacturing capabilities by 50%. However, this would require a…arrow_forwardS2→ S1→ S→ M→ D→ R→ C→ C1→C2Consider a FMCG firm which purchases raw material from different suppliers, manufacturer has variety of goods and sell across all Pakistan.a. Identify scope and structure of manufacturing firm.b. Identify 1st-Tier and 2nd-Tier supplier.c. Mention all possible dyadic relationship.arrow_forward

- Week 1 2 3 4 5 6 7 8 Retailer 110 110 190 190 310 310 410 410 Manufacturer 220 380 620 820 Supplier 600 1,440arrow_forwardwith the complexity of the product range and the need for high levels of quality, she has found it difficult to influence sourcing strategy. Formal procurement procedures and systems at PEC are very limited. Currently, the buyer waits to receive a requisition from the production function to place orders for equipment, materials and products. This means that orders are usually urgent and the buyer has little opportunity to review alternative suppliers or sourcing approaches. Low value maintenance, repair and operations (MRO) requirements cause particular problems as the requisitions are difficult to aggregate. This causes excessive and time-consuming administration for the buyer. Testing requirements Pressure testing machinery used for testing the quality of seams in the protective work-wear is nearing the end of its life and will soon require replacement. Product testing is essential to confirm final quality of manufacture and conformance to industry standards. The test equipment is…arrow_forward

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON

Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning

Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON

Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON

Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON

Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON