Materials Science And Engineering Properties

1st Edition

ISBN: 9781111988609

Author: Charles Gilmore

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

This is an old exam practice question. The answer key says the answer is Pmax = 52.8kN but I am confused how they got that.

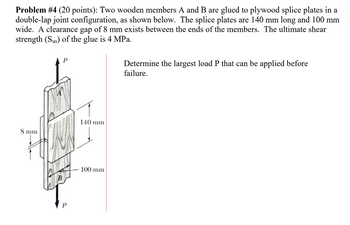

Transcribed Image Text:Problem #4 (20 points): Two wooden members A and B are glued to plywood splice plates in a

double-lap joint configuration, as shown below. The splice plates are 140 mm long and 100 mm

wide. A clearance gap of 8 mm exists between the ends of the members. The ultimate shear

strength (Sus) of the glue is 4 MPa.

P

Determine the largest load P that can be applied before

failure.

140 mm

8 mm

B

P

100 mm

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- A tensile test was performed on a metal specimen having a circular cross section with a diameter 0. 510 inch. For each increment of load applied, the strain was directly determined by means of a strain gage attached to the specimen. The results are, shown in Table: 1.5.1. a. Prepare a table of stress and strain. b. Plot these data to obtain a stress-strain curve. Do not connect the data points; draw a best-fit straight line through them. c. Determine the modulus of elasticity as the slope of the best-fit line.arrow_forwardThe data in Table 1.5.3 were obtained from a tensile test of a metal specimen with a rectangular cross section of 0.2011in.2 in area and a gage length (the length over which the elongation is measured) of 2.000 inches. The specimen was not loaded to failure. a. Generate a table of stress and strain values. b. Plot these values and draw a best-fit line to obtain a stress-strain curve. c. Determine the modulus of elasticity from the slope of the linear portion of the curve. d. Estimate the value of the proportional limit. e. Use the 0.2 offset method to determine the yield stress.arrow_forwardIn Example Problem 12.1, a uniaxial composite material is made into a circular rod Vbith a 1.27-cm diameter from 70 volume percent continuous carbon fibers and 30 volume percent epoxy. The rod is subject to an axial force of 100,000 N. The composite matcrial in Example Problem 12.1 is to be replaced with a less expensive composite made of 70 volume percent continuous E-glass fibers and 30 volume percent epoxy. The elastic moduli are 5 GPa for the epoxy resin and 72.4 GPa fos the E-glass. (a) Compare the elastic modulus, composite strain, fiber and matrix stresses, and density of this composite with the carbon epoxy composite in Example Problem 12.1. Usc the density of UHM carbon, and assume the density of the epoxy is 1.2g/cm3 . (b) Can both the E-glass fiber and matrix withstand the applied force?arrow_forward

- Use the composite beam tables and select a W-shape and stud anchors for the following conditions: Span length = 18 6 Beam spacing = 9 ft Total slab thickness = 51 2 in. (the slab and deck combination weighs 57 psf). Lightweight concrete with a unit weight of 115 pcf is used Construction load = 20 psf Partition load = 20 psf Live load = 225 psf Fy=50 ksi and fc=4 ksi A cross section of the formed steel deck is shown in Figure P9.8-9. The maximum live-load deflection cannot exceed L/360 (use a lower-bound moment of inertia). a. Use LRFD. b. User ASD.arrow_forwardThe frame of a space shuttle type vehicle must have a high yield strength and high stillness, and the most important design factor is weight. Of all the materials presented in this chapter, what material might be the most suitable for the frame of a space shuttle? Assume that there will be both tensile and compressive stresses. For a space shuttle, cost is not a limiting factor. (a) You can eliminate entire classes of materials from consideration with a brief statement about their unsuitability. (b) What material has the highest specific yield strength? Give the yield strength, specific gravity, specific yield strength, elastic modulus, and specific elastic modulus for this material. (c) What material has the highest specific elastic modulus? Give the yield strength, specific gravity, specific yield strength, elastic modulus, and specific elastic modulus for this material. (d) Compare the materials with the highest specific yield strength and highest specific elastic modulus for suitability in the space shuttle frame. (C) Discuss the suitability of the top-rated material for this design from the viewpoint of the ability to produce a frame.arrow_forwardA W1422 acts compositely with a 4-inch-thick floor slab whose effective width b is 90 inches. The beams are spaced at 7 feet 6 inches, and the span length is 30 feet. The superimposed loads are as follows: construction load = 20 psf, partition load = 10 psf, weight of ceiling and light fixtures = 5 psf, and live load = 60 psf, A992 steel is used, and fc=4 ksi. Determine whether the flexural strength is adequate. a. Use LRFD. b. Use ASD.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning, Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning

Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:9781111988609

Author:Charles Gilmore

Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...

Civil Engineering

ISBN:9781337094740

Author:Segui, William T.

Publisher:Cengage Learning

Solid Waste Engineering

Civil Engineering

ISBN:9781305635203

Author:Worrell, William A.

Publisher:Cengage Learning,

Construction Materials, Methods and Techniques (M...

Civil Engineering

ISBN:9781305086272

Author:William P. Spence, Eva Kultermann

Publisher:Cengage Learning