International Edition---engineering Mechanics: Statics, 4th Edition

4th Edition

ISBN: 9781305501607

Author: Andrew Pytel And Jaan Kiusalaas

Publisher: CENGAGE L

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

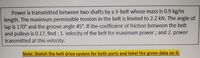

Transcribed Image Text:Power is transmitted between two shafts by a V-belt whose mass is 0.9 kg/m

length. The maximum permissible tension in the belt is limited to 2.2 kN. The angle of

lap is 170° and the groove angle 45°. If the coefficient of friction between the belt

and pulleys is 0.17, find : 1. velocity of the belt for maximum power; and 2. power

transmitted at this velocity.

Note: Sketch the belt drive system for both parts and label the given data on it.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 5 steps with 5 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The clutch described in Prob. 7.75 is to transmit a torque of 120lbft when the total spring force exerted on the pressure plate is 75 lb. If Ri=4in., calculate the minimum acceptable value for RO. Assume that the clutch is new.arrow_forwardIf PCD=6000lb and PGD=1000lb (both compression), find P and Q.arrow_forwardFind the power transmitted by a belt running over a pulley of 600 mm diameter at200 r.p.m. The coefficient of friction between the belt and the pulley is 0.25,angle of lap 160° and maximum tension in the belt is 2500 N.arrow_forward

- Homework 2 A pulley is driven by a flat belt, the angle of lap being 120º. The belt is 100 mm wide by 6 mm thick and density1000 kg/m3. If the coefficient of friction is 0.3 and the maximum stress in the belt is not to exceed 2 MPa, find the greatest power which the belt can transmit and the corresponding speed of the belt.arrow_forwardQ3: An open belt drive with (200 and 150 mm) pulleys diameters, and the central distance equal to (0.5 m). The larger pulley speed is (500 r.p.m.), and the coefficient of friction between the belt and the pulley is (0.35). Calculate the power transmitted by the belt drive when the maximum tension on the belt equal to (2200 N).arrow_forward. Find the width of the belt, necessary to transmit 7.5 kW to a pulley 300 mm diameter, if the pulley makes 1600 r.p.m and the coefficient of friction between the belt and the pulley is 0.22. Assume the angle of contact as 210° and the maximum tension in the belt is not to exceed 8 N/mm width.arrow_forward

- Question 4 A pulley is driven by a flat belt, the angle of lap being 120°. The belt is 100 mm wide by 6 mm thick and density is 1000 kg/m. If the coefficient of friction is 0.3 and the maximum stress in the belt is not to exceed 1.5 MPa. Calculate: 4.1. 4.2. the speed of the belt in m/s using the information related to driving pulley. the centrifugal tension and the tension on the first tight side of the belt T1. the greatest power the belt can transmit. 4.3arrow_forwardA multi-disk clutch consists of two steel disks with one bronze disk. Theinner and outer diameters of the contacting surfaces are 200 and 250 mmrespectively. The coefficient of friction is 0.1 and the maximum pressurebetween the contacting surfaces is limited to 0.4 N/mm2. Assuming uniformwear theory, calculate the required force to engage the clutch and the powertransmitting capacity at 720 rpmarrow_forwardV-belt calculationarrow_forward

- A multiplate clutch has three pairs of contact surfaces. The outer and inner radii of the contact surfaces are 100 mm and 50 mm respectively. The maximum axial spring force is limited to 1 kN. If the coefficient of friction is 0.35 and assuming uniform wear, find the power transmitted by the clutch at 1500 r.p.m.arrow_forwardIn an open flat belt drive, a pulley of 800 mm diameter runs at 300 r.p.m. The coefficient of friction between the belt and the pulley is 0.25, the angle of lap is 170° and the maximum tension in the belt is 2000 N. The power transmitted is: 10.5 kW 9.4 kW 8.9 kW 7.6 kW None of the mentioned 13.1 kWarrow_forwardDetermine the percentage increase in power capacity made possible in changing over from flat belt drive to V-belt drive. The diameter of pulley is same as the pitch diameter of grooved pulley. The pulley rotates at the same speed as the grooved pulley. The coefficient friction for the grooved and flat belt is same and is 0.3. The V-belt pulley groove angle is 60°. The belts are of the same material and have same cross-sectional area. In each case, The angle of warp is 150°.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

International Edition---engineering Mechanics: St...Mechanical EngineeringISBN:9781305501607Author:Andrew Pytel And Jaan KiusalaasPublisher:CENGAGE L

International Edition---engineering Mechanics: St...Mechanical EngineeringISBN:9781305501607Author:Andrew Pytel And Jaan KiusalaasPublisher:CENGAGE L

International Edition---engineering Mechanics: St...

Mechanical Engineering

ISBN:9781305501607

Author:Andrew Pytel And Jaan Kiusalaas

Publisher:CENGAGE L