Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

The demand for assembly of product A is 150 units at the start of week 6. Each unit of product A needs 2 units of part T and 3 units of part U. Each unit of part T requires 2 units of part V, 1 unit of part W, and 4 units of part X. Also, each unit of part U requires 3 units of part Y and 1 unit of part X. It takes 1 week to make part A, 2 weeks to make part T, 2 weeks to make part U, 2 weeks to make part V, 3 weeks to make part W, 1 week to make part X, and 2 weeks to make part Y. One firm manufactures all items.

a) Construct a product BOM.

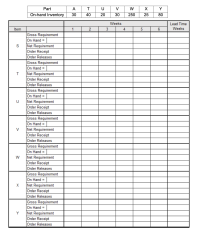

b) Construct the MRP table using the following on-hand inventory

Transcribed Image Text:Part

A

T

V

W

Y

On-hand Inventory

30

40

20

30

250

25

80

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- The product structure for product X is illustrated below. Level 0 Level 1 4 Level 2 Level 3 Part H B C D H K M N X Z с K B Lead Time (in weeks) 1 1 3 2 3 2 3 3 4 M D N The lead time for manufacturing any number units for an item and the required number of units for the lower level part in the product structure are reported in the following table. For example, each unit of Part X requires 1 units of Part C and, in turn, each unit of Part C requires 2 units of Part H and 2 units of Part K. 2 1 4 2 2 2 4 1 2 Required number of units X Z H K 100 units of product X are to shipped at the end of week 25. There is no inventory on hand. How many units of part N are required for production? 3200 Specify only the number.arrow_forwardA production process at Brianna Bryant Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). 6 units/hr 2.5 units/hr Sawing Sanding Q Assembly 0.8 units/hr Welding 5 units/hr Assembly 0.8 units/hr Drilling 2.1 units/hr a) is the bottleneck. b) The bottleneck time is minutes per unit (round your response to two decimal places). c) The throughput time of the overall system is minutes (round your response to two decimal places). Assembly 0.8 units/hr d) If the firm operates 11 hours per day, 20 days per month, the monthly capacity of the manufacturing process is units (enter your response as a whole number).arrow_forwardThe diagram below represents a process where two components are made at stations A1 and A2 (one component is made at A1 and the other at A2). These components are then assembled at station B and moved through the rest of the process, where some additional work is completed at stations C, D, and E. Assume that one and only one person is allowed at each station. Assume that the times given below for each station represent the amount of work that needs to be done at that station by that person, with no processing time variation. Assume that inventory is not allowed to build in the system. Al 0.3 min. A2 0.4 min. B 0.75 min. D 0.65 min. 0.60 min. E 0.55 min. What is the average hourly output of the process when it is in normal operation? Average hourly output unitsarrow_forward

- The total manufacturing overhead cost allocated to the Basic model and the Advanced model using the activity-based approach. BASIC ADVANCED ACTIVITY ACTVIVITY RATE ACTIVITY OVERHEAD ACTIVITY OVERHEAD MACHINING 18.98 12,000.00 227,760.00 10,000.00 189,800.00 ASSEMBLE AND PACK 9.42 20,000.00 188,400.00 10,000.00 94,200.00 ORDER PROCESSING 920.00 50.00 46,000.00 200.00 184,000.00 SETUPS 523.08 50.00 26,154.00 600.00 313,848.00 TOTAL MANUFACTURING OVERHEAD 488,314.00 781,848.00 The total…arrow_forwardAn assembly line is to be designed to operate 13 hours per day and supply a steady demand of 325 units per day. Here are the tasks and their performance times: TASK PRECEDINGTASKS PERFORMANCE TIME (SECONDS) TASK PRECEDINGTASKS PERFORMANCETIME (SECONDS) a — 48 g d 43 b — 58 h e 38 c — 73 i f 23 d a 63 j g 33 e b 88 k h, i 53 f c 23 l j, k 67 A) What is the efficiency of your line balance? B) Suppose demand increases by 10 percent. How would you react to this? Assume that you can operate only 13 hours per day in regular time. (Round your answers to the nearest whole number.)arrow_forwardWhat is the relationship between ERM and ERD? What are their respective components? How does UML come into play?arrow_forward

- A medical equipment testing and calibration service is shown below. The customer usually brings the equipment to the service center. The service process requires service technicians to perform three process steps #1 to #3. Each technician is cross-trained so they can perform any of the three steps. The inspector does step #4 alone. After step #4, two parallel work activities are performed. That is, a shipping clerk packs the work (step #7), while simultaneously, a billing clerk prepares the invoice (step #5), and the customer is contacted by phone for pick-up (step #6). The average throughput is three equipment units per hour. The table below shows the work content of the process steps, activity times in minutes per unit, shared and non-shared work activities, and the type of resource required. There are three service technicians on duty, one inspector, one billing clerk, and one shipping clerk. Activity Time Activity Activity (minutes) Performed By Start - 1 7 Service…arrow_forwardProduct Z is made from three units of A, two of B, and four of C. A, in turn, is made of one unit of C and five of D. A customer order was received for 200 units of Z in Week 8. (Hint: You will need to use "low-level coding", i.e., pull each item to the lowest level it appears on the BOM.) Item Lot Size On Hand Lead Time Z LFL 30 3 A LFL 40 1 B LFL 100 4 C 1000 50 3 D 500 2000 3 a. Show the Bill of Materials b. Develop MRP schedules showing gross/net requirements and planned order releases/receipts for each item.arrow_forwardAbnormal spoilage was 100 units and normal spoilage is 400 units. Beginning Work-in-ProcessInventory consisted of 5,000 units; 20,000 units were started; and 22,000 units were completed thisperiod. How many units were in ending Work-in-Process?arrow_forward

- A production process at Brianna Bryant Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). a) is the bottleneck. 1.8 units/hr Sawing minutes per unit (round your response to two decimal places). 5 units/hr Sanding Drilling 5 units/hr b) The bottleneck time is c) The throughput time of the overall system is minutes (round your response to two decimal places). d) If the firm operates 11 hours per day, 20 days per month, the monthly capacity of the manufacturing process is Welding 2.5 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr units (enter your response as a whole number). Qarrow_forwardA production process at Brianna Bryant Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). a) is the bottleneck. 1.8 units/hr Sawing minutes per unit (round your response to two decimal places). 5 units/hr Sanding Drilling 5 units/hr b) The bottleneck time is c) The throughput time of the overall system is minutes (round your response to two decimal places). d) If the firm operates 11 hours per day, 20 days per month, the monthly capacity of the manufacturing process is Welding 2.5 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr units (enter your response as a whole number). Qarrow_forwardA production process at Kenneth Day Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). 2.1 units/hr Sawing 5 units/hr Sanding Drilling 5 units/hr Welding 2.5 units/hr a) Sawing is the bottleneck. b) The bottleneck time is 28.57 minutes per unit (round your response to two decimal places). c) The throughput time of the overall system is 89.58 minutes (round your response to two decimal places). Assembly Q 0.8 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hrarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.