Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

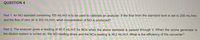

Transcribed Image Text:QUESTION 4

Part 1: An NO standard containing 100 mL/m3 is to be used to calibrate an analyzer. If the flow from the standard tank is set to 200 mL/min,

and the flow of zero air is 300 mL/min, what concentration of NO is produced?

Part 2: The analyzer gives a reading of 40.0 mL/m3 for NOx when the above standard is passed through it. When the ozone generator in

the dilution system is turned on, the NO reading drops and the NOx reading is 39.2 mL/m3. What is the efficiency of the converter?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- A simple batch still (one equilibrium stage) is separating a 50 mole feed charge to the still pot that is 80.0 mol% methanol and 20.0 mol% water. An average distillate concentration of 88.6 mol% methanol is required. Find the amount of distillate collected, the amount of material left in the still pot, and the concentration of the material in the still pot. Pressure is 1 atm. Note: There's no additional information to the question above.arrow_forwardA chemical engineer must calculate the maximum safe operating temperature of a high-pressure gas reaction vessel. The vessel is a stainless-steel cylinder that measures 54.0 cm wide and 64.8 cm high. The maximum safe pressure inside the vessel has been measured to be 7.40 MPa. For a certain reaction the vessel may contain up to 9.04 kg of carbon dioxide gas. Calculate the maximum safe operating temperature the engineer should recommend for this reaction. Write your answer in degrees Celsius. Round your answer to 3 significant digits. temperature: || °C |x10 ?arrow_forwardProblem 2: Liquid-liquid extraction A liquid feed stream of 1500 kg/h consisting of 35 wt. % acetonitrile (1) and 65% water (2) is to be extracted using isobutyl methyl ketone (3) as the solvent. If the flow rate of the solvent is 500 kg/h, determine the flow rates and compositions of the exit streams using the phase diagram (mass fractions) below. The overall process takes place at a constant temperature of 303 K. Acetonitrile OA 1 Extract Phase 0.2 0.8 0.4 0.6 F 0.6 E 0.4 F M 0.8 0.2 Raffinate Phase Isobutyl 1 methyl ketone 0.2 0.4 0.6 0.8 1° Water Settler,arrow_forward

- A container contains 600 kg solution which includes 6% sugar. It is homogeneously stirred. Another solution which includes 15% sugar is entering the container at 1000 kg/h constant flow rate. At the same time, it is also started a constant withdrawal rate at 700 kg/h. Derive an equation that relates the concentration of outlet withdrawal as a function of time. Calculate the concentration after 1.5 hours as well.arrow_forward10. A container is separated into two halves by a membrane. Your lab partner assistant, Thurmond, is supposed to place a MgCl2 solution on side 1 and a NaCl solution on side 2. He is then supposed to measure the rate of water movement across the membrane. Unfortunately, Thurmond is not very good about keeping complete lab notes and he has forgotten to write down some data and calculations. Using your knowledge of osmosis, complete the following table. Temperature is 15°C and the hydraulic conductivity for the membrane is 0.4 ml/atm sec. MgCl2 Concentration on Side 1 NaCl Concentration on Side 2 80 mM Osmolarity on Side 1 Osmolarity on Side 2 Difference in osmotic pressure 60 mosM across the membrane Jy 0.95 ml/sec Reflection coefficient (ơ) Direction of water movementarrow_forwardA feed of a distillation column contains 40 mol% of n-pentane and 60 mol% of n-hexane will be separated to recover 92 mol% of n-pentane as distillate at the column condition of 1 atm. The column receives a saturated liquid feed with a flow rate of 1,200 kmol/h. A total condenser is used and reflux is a saturated liquid. Bottoms from the column contains 94 mol% of n-hexane from the feed. The carbon steel column is equipped with carbon steel sieve trays which have efficiency of 43%. Determine the design specifications of the distillation column using the appropriate heuristics. Hint: You need to find densities for vapour of distillate by using the chemical engineering principles that you have learnt. Use data in Table 2 and equation below to determine relative volatility of component.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The